Controllable atmosphere rotary hearth furnace process for producing direct reduction iron

A technology of rotary hearth furnace and reduced iron, which is applied in the field of production of reduced iron, which can solve the problems of reducing the coke ratio, leakage of double-screw discharger, and low iron grade, so as to increase production, avoid secondary oxidation, and improve The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

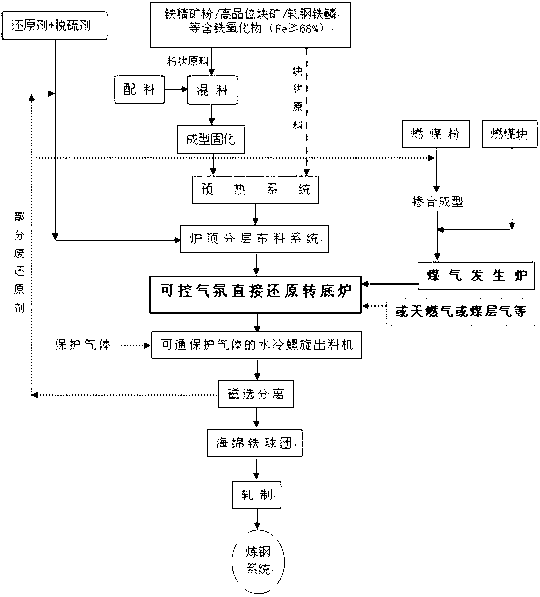

[0022] Embodiment 1: as figure 1 As shown, the reducing agent used in this embodiment is a mixture of anthracite and desulfurizing agent, the quality of anthracite: the quality of desulfurizing agent=1:0.15, the present invention is carried out according to the following steps: (1) powdery iron-containing oxide and binder Mix the materials at a weight ratio of 1:0.01, and then use a forming machine to roll them into pellets with a diameter of 30mm; (2) Put the pellets into the grate rotary kiln and preheat to 800°C; (3) The preheated material The material is sent to the 2-stage distribution port of the furnace roof through the feeder; the controllable atmosphere rotary hearth furnace top is equipped with 3 height-adjustable distributors, and the 1st and 3rd-level distribution ports are equipped with reducing agents, and the reducing agent is anthracite. Quality: quality of desulfurizer = 1:0.15, 2nd level distribution of iron pellets; (4) distribution operation: controllable a...

Embodiment 2

[0023] Embodiment 2: as figure 1 A controllable atmosphere rotary hearth furnace process for the production of direct reduced iron is shown, which is carried out in the following steps:

[0024] (1) Mix powdery iron-containing oxide, binder and carbon powder at a weight ratio of 1:0.01:0.15, and then use a molding machine to roll into internal carbon pellets with a diameter of 30mm;

[0025] (2) The internal carbon pellets are preheated to 900°C through the grate rotary kiln;

[0026] (3) The preheated material is sent to the second-stage material distribution port on the top of the rotary hearth furnace through the feeder;

[0027] (4) Material distribution operation: the bottom plate of the controllable atmosphere rotary hearth furnace rotates counterclockwise, and carbon pellets are distributed from the second-level material distribution port, and the material distribution height is set to 70mm;

[0028] (5) All the materials are run in the rotary hearth furnace at about ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com