Diamond thick film prepared with direct-current plasma jet method

A diamond thick film, plasma technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve problems such as diamond tool restriction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

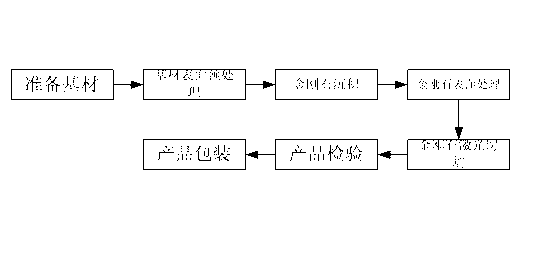

[0020] When producing thick diamond films, the following steps are used:

[0021] 1) Prepare the substrate: Mo is generally used as the substrate material;

[0022] 2) Substrate surface pretreatment: Use diamond powder to pre-grind or pre-sow seed crystals on the substrate surface. In particular, W20 diamond powder was used for pretreatment. ;

[0023] 3) Diamond deposition: 150 kW DC arc plasma spraying equipment is used to deposit diamond on the surface of the substrate, at a high temperature of 1180 ° C and 10 5 Under the high pressure of Pa, argon, hydrogen and methane are fully mixed according to the volume ratio of 10-20:5-9:1-6, and the diamond is deposited on the surface of the substrate at a flow rate of 20-40 l / min. The deposition rate of diamond is 0~20 microns / hour;

[0024] 4) Diamond surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com