Integrated microfluidic spinning chip and method for preparing regenerated silk fibroin by using same

A technology for regenerating silk fibroin and microfluidics, which is applied in the direction of single-component fibroin artificial filaments, dry spinning, artificial silk manufacturing, etc., and can solve the problem that microfluidic spinning chips are too simple, have low degree of bionics, and have single functions and other problems, to achieve the effect of improving the degree of bionic spinning, improving the degree of bionics, and simplifying the operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

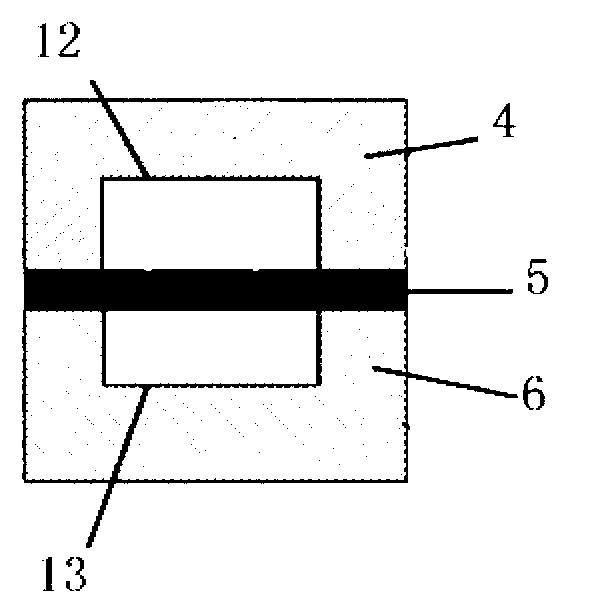

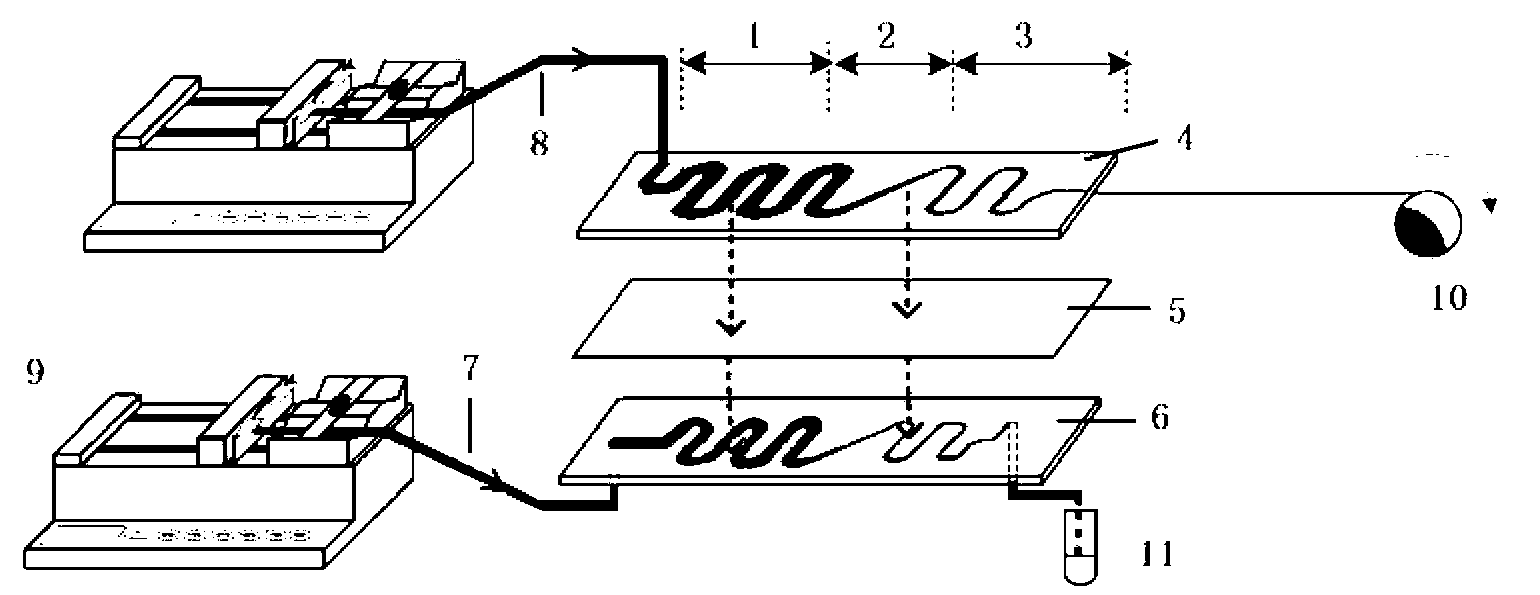

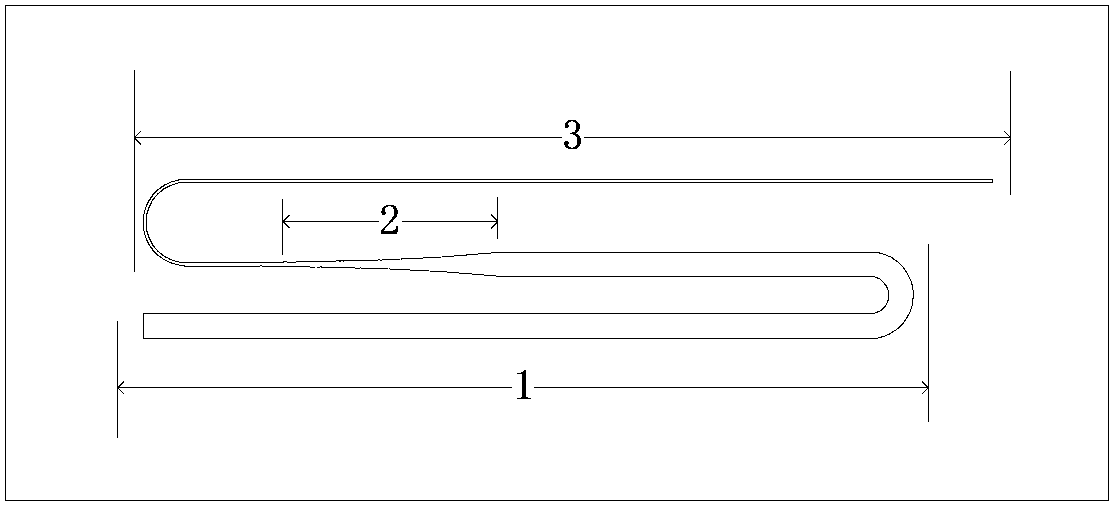

[0067] The microfluidic chip of the present invention is a three-layer structure, including the upper and lower PDMS membranes and the middle dialysis membrane layer. There are grooves on the PDMS membrane, and the grooved surfaces of the upper and lower membranes are bonded to the dialysis membrane to form an upper and lower membrane. Two microfluidic channels; the channels have an equal depth of 50 μm throughout. The horizontal cross-sectional shape of the microfluidic channel in the lower layer is in a mirror image relationship with the horizontal cross-sectional shape of the upper layer channel. The channels are arranged in a longitudinal serpentine shape on the diaphragm: the serpentine channel in the adjustment section has 3 bends, the width is 2mm, the vertical part of the channel is 7mm long, and the diameter of the semicircle of the curved part is 4mm; the shearing section has 3 Each bend has a width of 150 μm, the length of the vertical part of the serpentine channel...

Embodiment 2

[0071]The microfluidic chip of the present invention is a three-layer structure, including the upper and lower PDMS membranes and the middle dialysis membrane layer. There are grooves on the PDMS membrane, and the grooved surfaces of the upper and lower membranes are bonded to the dialysis membrane to form an upper and lower membrane. Two microfluidic channels; the horizontal cross-sectional shape of the lower microfluidic channel is in a mirror image relationship with the horizontal cross-sectional shape of the upper channel. The depth of the entire microfluidic channel is equal to 100 μm. The microfluidic channels are arranged in a longitudinal serpentine shape on the membrane: the serpentine channel in the adjustment section has 2 bends, the width is equal to 2.5 mm, the vertical part of the channel is 8 mm long, and the diameter of the semicircle of the curved part is 10 mm; The cut section has 2 bends, the width is 200 μm, the vertical part of the serpentine channel is 10...

Embodiment 3

[0075] The microfluidic chip of the present invention is a three-layer structure, including the upper and lower PDMS membranes and the middle dialysis membrane layer. There are grooves on the PDMS membrane, and the grooved surfaces of the upper and lower membranes are bonded to the dialysis membrane to form an upper and lower membrane. Two microfluidic channels; the horizontal cross-sectional shape of the lower microfluidic channel is in a mirror image relationship with the horizontal cross-sectional shape of the upper channel. The depth of the whole microfluidic channel is equal to 85 μm. The microfluidic channels are arranged in a longitudinal serpentine shape on the membrane: the serpentine channel in the adjustment section has 3 bends, the width is equal to 2.5 mm, the vertical part of the channel is 7 mm long, and the diameter of the semicircle of the curved part is 9 mm; The section has a bend with a width of 300 μm, the vertical part of the serpentine channel is 10 mm l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com