Variable load multiple ultra-low speed inner curve wind energy absorbing plunger pump

An inner curve, ultra-low speed technology, applied in the field of wind energy absorption plunger pump, can solve the problems of large volume, poor speed-up performance, large quality, etc., to achieve high overall efficiency, improve pump working conditions, and reduce leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

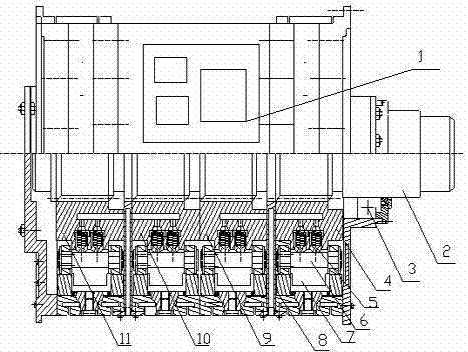

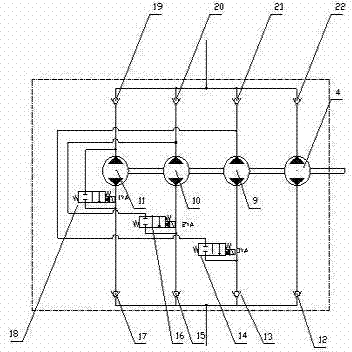

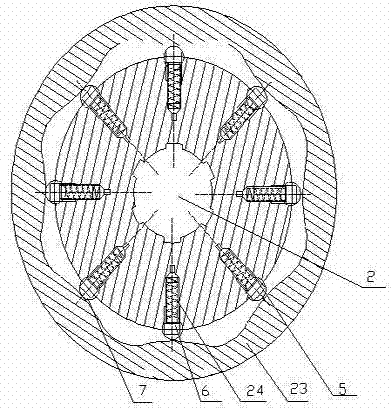

[0017] The variable load multi-connected ultra-low speed internal curve wind energy absorption plunger pump consists of a controller 1, a main shaft 2, a rolling bearing 3, a first rotor 4, a plunger 5, a beam 6, a roller 7, a flow distribution plate 8, a second rotor 9, and a second rotor. Three rotors 10, fourth rotor 11, first one-way valve 12, second one-way valve 13, first two-position four-way electromagnetic reversing valve 14, third one-way valve 15, second two-position four-way electromagnetic reversing valve One-way valve 16, fourth one-way valve 17, third two-position four-way solenoid directional valve 18, fifth one-way valve 19, sixth one-way valve 20, seventh one-way valve 21, eighth one-way valve 22 , Stator 23, back-moving spring 24, sealing ring 25 are formed.

[0018] The main shaft 2 has four external splines in the axial direction, the inner surfaces of the first rotor 4, the second rotor 9, the third rotor 10 and the fourth rotor 11 have internal splines, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com