LED (Light-Emitting Diode) lamp housing with anticorrosive, heat-dissipation, high-insulation ceramic thermal spraying mode

A technology of LED lamps and thermal spraying, applied in lighting and heating equipment, damage prevention measures for lighting devices, semiconductor devices of light-emitting elements, etc., can solve problems affecting heat dissipation effects, etc., achieve low production cost, long service life, and production high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

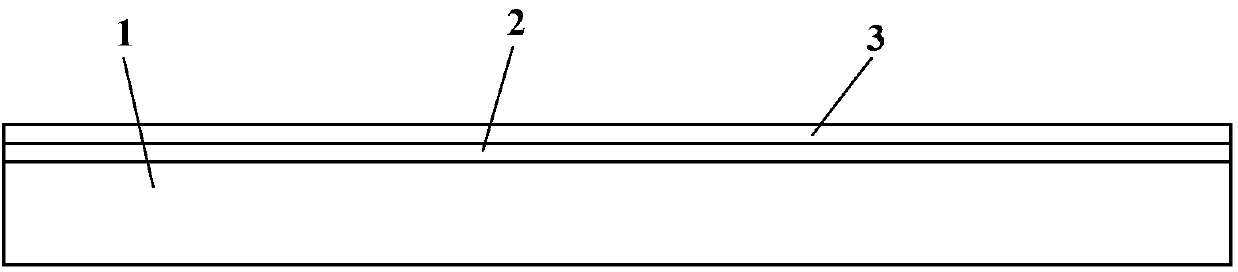

[0015] From attached figure 1 It can be seen from the structural schematic diagram that this embodiment provides an LED lamp shell with anti-corrosion and heat dissipation high-insulation ceramic thermal spraying mode, which includes a metal shell 1, a ceramic coating 3 coated on the surface of the metal shell 1, and the surface of the metal shell 1 It has a rough surface layer 2 formed after the oxide layer is removed by grinding, and a ceramic coating 3 is coated on the rough surface layer 2 .

[0016] The metal shell 1 can be metal lamp shells of various shapes and sizes, and can also be a metal heat dissipation bar or a heat dissipatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com