Bio vapor stimulation system

A biological and steam technology, applied in gas production bioreactors, biochemical equipment and methods, and microbial determination/inspection, etc., can solve problems such as uneven distribution of moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

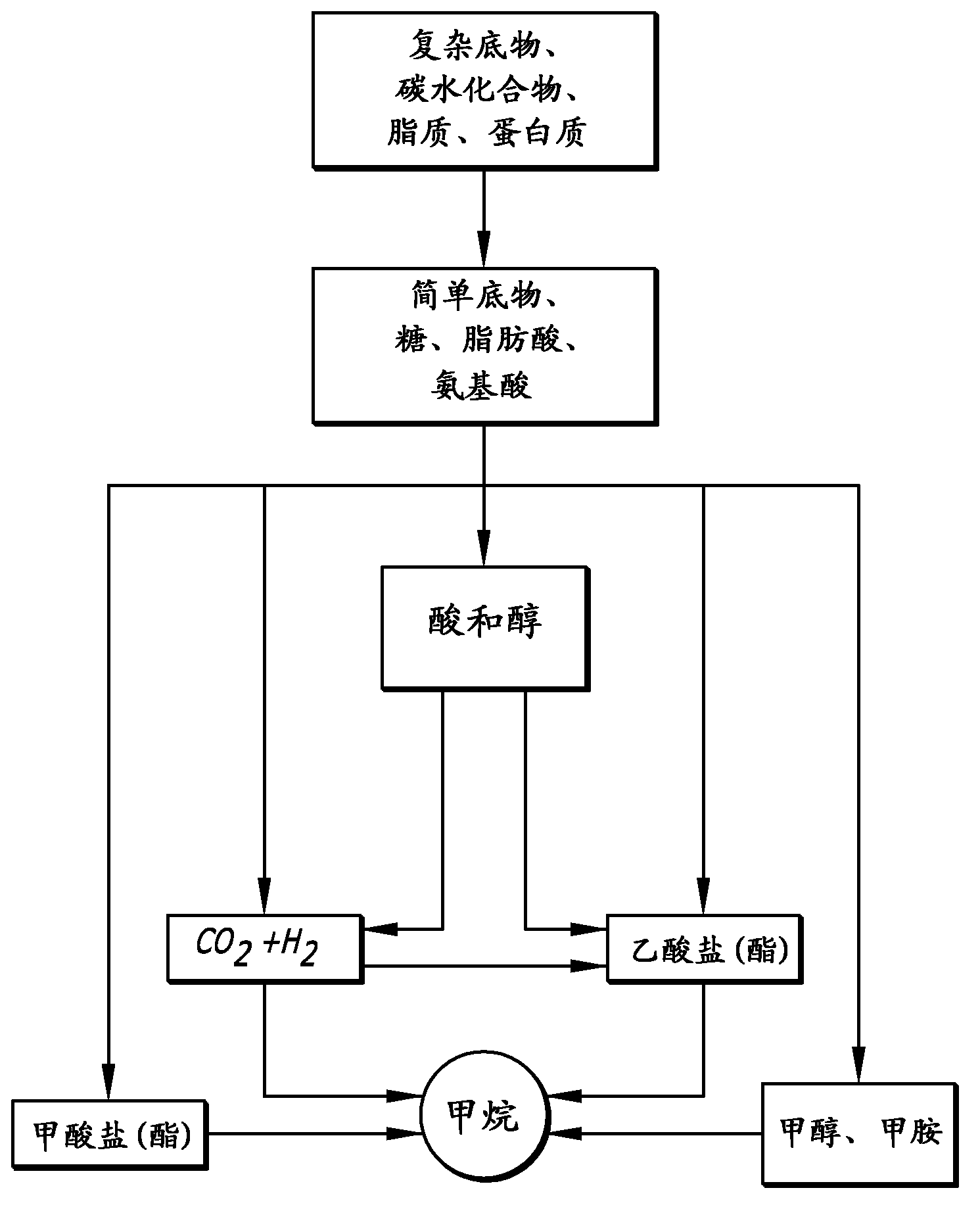

[0036] Desired degradation of organic compounds by hydrogen-producing bacteria as long as hydrogen partial pressure can be kept below -4 Atmospheric pressure will happen.

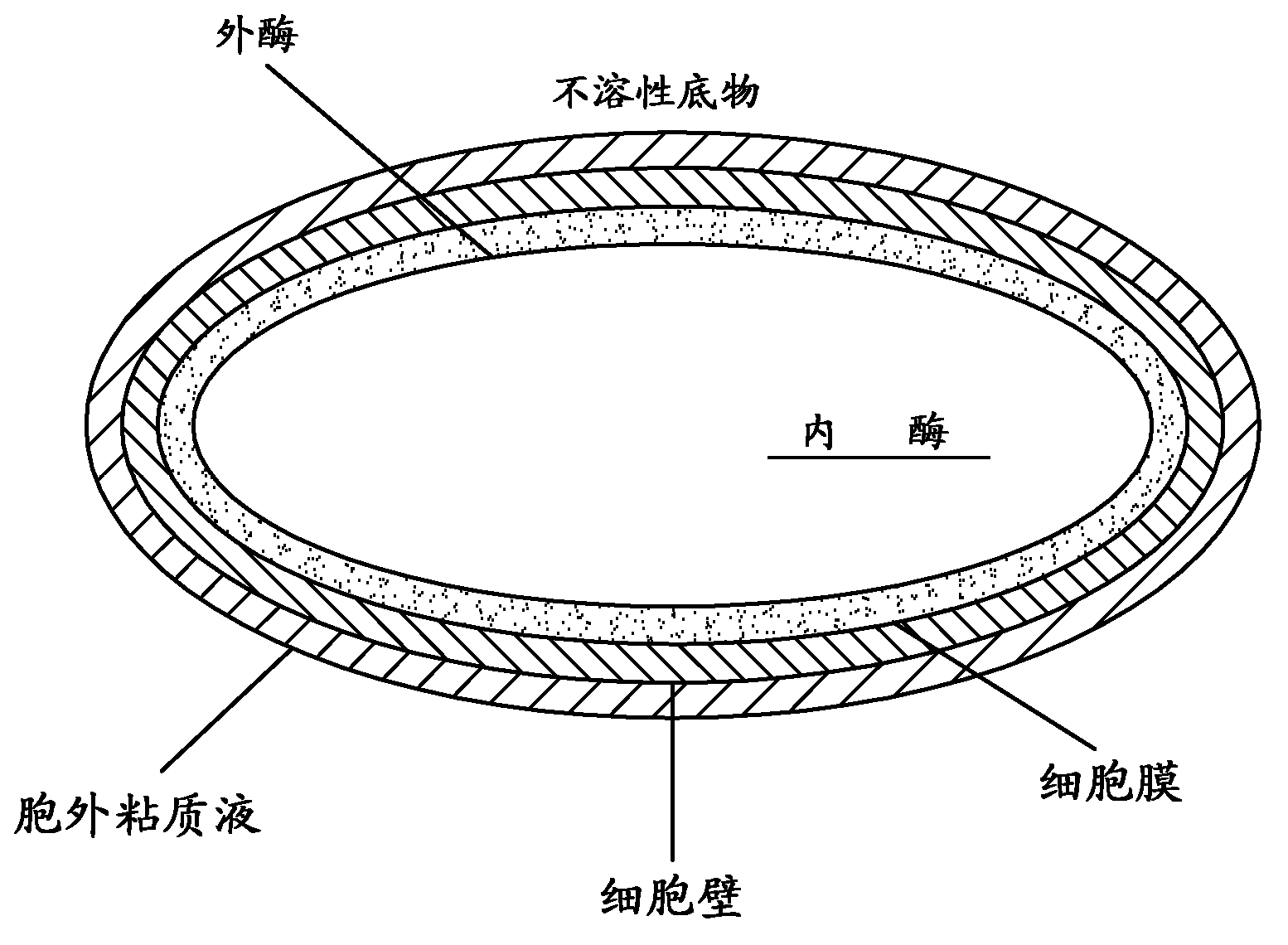

[0037] No single species of bacteria produces all the extracellular enzymes required for the degradation of the large variety of particulate and colloidal substrates found in solid waste and other biomass. Each exoenzyme, as well as each endoenzyme, only degrades a specific substrate or group of substrates.

[0038] Therefore, a large and diverse population of bacteria is required to ensure that the appropriate types of endo- and exo-enzymes are available to degrade existing substrates. Table 3 exemplifies the enzymes required for certain substrates, while Table 4 exemplifies how enzymes are used in the critical pathway for the formation of methane from solids.

[0039] Methane gas production by anaerobic bacteria can be facilitated by coenzymes. Coenzymes are metal-loaded organic acids that are introduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com