Zinc alloy chilling alcohol group paint by utilizing melt and sublimation of substance to absorb heat

A zinc alloy and alcohol-based technology, applied in the field of coatings for casting metal molds and chilling coatings, can solve the problems of reduced surface quality of castings, exposure of non-fine grain areas, affecting design efficiency, etc., to increase cooling speed and improve mechanical properties , The effect of reducing the design cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] Alcohol-based coatings for zinc alloy metal mold casting were formulated in the weight percentages (%) shown in the following table:

[0026] Table 1 Coating formulation

[0027]

[0028] Table 2 Alcohol-based solvent formula

[0029]

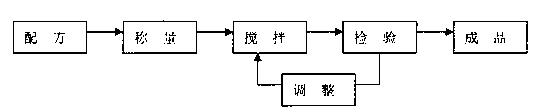

[0030] Such as figure 1 According to the above table, formulate, weigh, stir, test the basic properties of the suspension, surface strength, and gas generation of the paint, adjust, and re-stir the test to make the finished paint; where: when adding materials, pay attention to the suspending agent, binder and additives. Add graphite powder, zinc oxide, tin powder and sulfur powder in turn after mixing the agent and solvent evenly; prepare 1 kg of chilled coating in a single batch, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com