Shale brick processing process with low radon exhalation rate

A technology of radon precipitation rate and processing technology is applied in the field of processing technology of shale bricks with low radon precipitation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

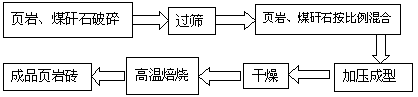

[0015] A processing technology for shale bricks with a low radon precipitation rate. This process is to crush and mix the main raw materials shale and coal gangue, and then press molding, drying and roasting to make shale bricks. The process flow chart is as follows figure 1 shown. The specific operation method is:

[0016] First, the raw material shale is crushed four times, and the coal gangue is crushed twice, and then the crushed raw materials are stored in different storage warehouses, and are screened by a vibrating screen with an aperture of 2 mm, and those larger than this size are returned to the crushing process. The final stage is crushed and then mixed with a sensor, the ratio is 1:1.

[0017] Secondly, pressurize the mixed material at 80kPa, dry at 80°C, and bake at 1000°C to obtain finished shale bricks.

[0018] The shale bricks prepared by this process are adsorbed by activated carbon boxes, and then measured by a high-purity germanium gamma spectrometer, an...

Embodiment 2

[0020] The process method and steps are the same as those in the examples, except that the negative pressure used in this process is 75kPa, the mixing ratio of shale and coal gangue is 3:2, the drying temperature is 100°C, and the roasting temperature is 1020°C . The shale bricks prepared by this process are adsorbed by activated carbon boxes, and then measured by high-purity germanium gamma spectrometer, and the radon precipitation rate of shale bricks is 2.251±0.18mBq.m -2 .s -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com