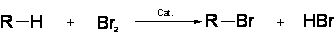

Bromination reaction method

A technology of bromination reaction and reaction formula, which is applied in the field of organic synthesis, can solve problems such as unfavorable large-scale industrial production, influence of target product yield, and bromination reaction does not avoid water, so as to improve the production environment, facilitate separation, and reduce consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Preparation of m-bromonitrobenzene.

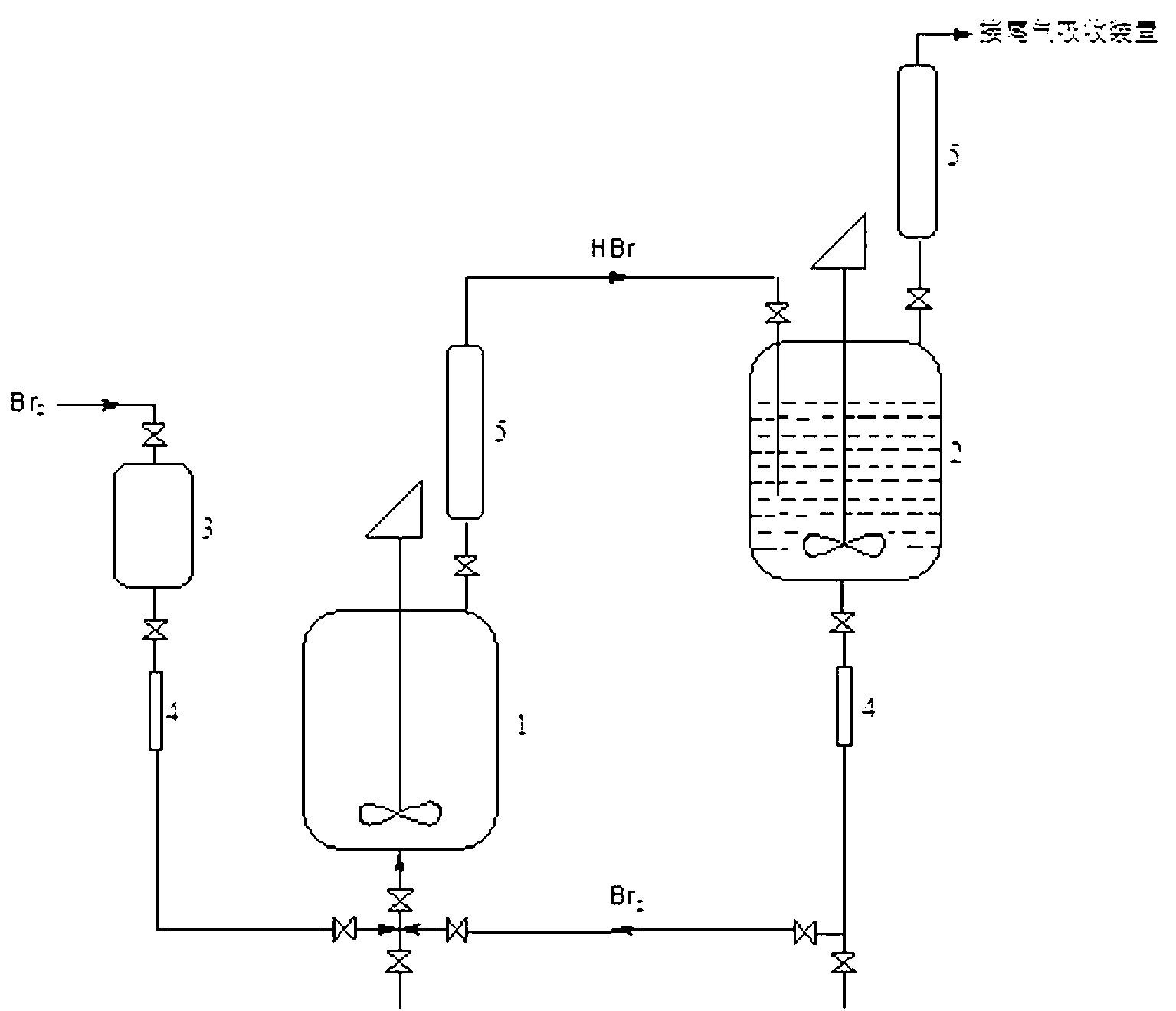

[0027] Take 16.8kg of liquid bromine in the bromine metering tank 3 for use; add three-quarters of the volume to the bromine regeneration tank 2 with condenser 5 containing 25% free SO 3 To maintain the temperature of the bromine regeneration tank 2 at 35℃~60℃.

[0028] Take 26.4kg of freshly steamed nitrobenzene and 0.2kg of iron powder into the brominated reaction tank 1 with condenser 5, stir evenly, raise the temperature of the oil bath to 135℃~145℃, and put the bromine metering tank 3 under rapid stirring. The liquid bromine in the bromine is slowly injected into the bromine reaction tank 1 from the bottom through the flow meter 4, and the injection rate is at the level of the substantially bromine-free steam overflow. The overflowing hydrogen bromide gas is passed into the fuming sulfuric acid in the bromine regeneration tank 2 through the pipe In the regeneration.

[0029] After the liquid bromine in the bromine metering...

Embodiment 2

[0032] Example 2: Preparation of 9-bromophenanthrene.

[0033] Take 16.6kg of liquid bromine and put it in the bromine metering tank 3 for use; add three-quarters of the volume to the bromine regeneration tank 2 with condenser 5 containing 20% free SO 3 To maintain the temperature of the bromine regeneration tank 2 at 35℃~60℃.

[0034] Take 35.6kg of refined phenanthrene, 0.1kg of iodine, and 70L of dry carbon tetrachloride into the brominated reaction tank 1 with condenser 5, stir well, and raise the temperature to slightly boiling. Under rapid stirring, the liquid bromine in the bromine metering tank 3 is slowly injected into the brominated reaction tank 1 from the bottom through the flow meter 4, and the injection rate is to maintain the slightly boiling of the reaction liquid. The overflowing hydrogen bromide gas is introduced through the pipe The bromine regeneration tank 2 is regenerated in fuming sulfuric acid.

[0035] After the liquid bromine in the bromine metering tank ...

Embodiment 3

[0038] Example 3: Preparation of tetrabromoparaene.

[0039] Take 67.5kg of liquid bromine and put it in the bromine metering tank 3 for use; add three-quarters of the volume to the bromine regeneration tank 2 with condenser 5 containing 40% free SO 3 To maintain the temperature of the bromine regeneration tank 2 at 35℃~60℃.

[0040] Take 21.2 kg of o-xylene and 100 L of dry carbon tetrachloride into the brominated reaction tank 1 with condenser 5, stir evenly, and raise the temperature to reflux. Stir quickly and under the irradiation of a 500W ultraviolet lamp, the liquid bromine in the bromine metering tank 3 is slowly injected into the bromine reaction tank 1 from the bottom through the flow meter 4, and the injection rate is basically no bromine overflow, and the overflowing bromine The hydrogen gas is passed into the fuming sulfuric acid in the bromine regeneration tank 2 through the pipe for regeneration.

[0041] After the liquid bromine in the bromine metering tank 3 is add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com