Method for co-producing furfural and 5-hydroxymethylfurfural by using lignocellulose-containing biomass

A technology of lignocellulose and hydroxymethylfurfural, applied in the field of biomass chemistry, can solve the problems that the yield needs to be further improved, achieve the effects of improving resource utilization efficiency, low price, and solving recycling problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Mechanically mix cellulose and sodium bisulfate at a mass ratio of 100:1;

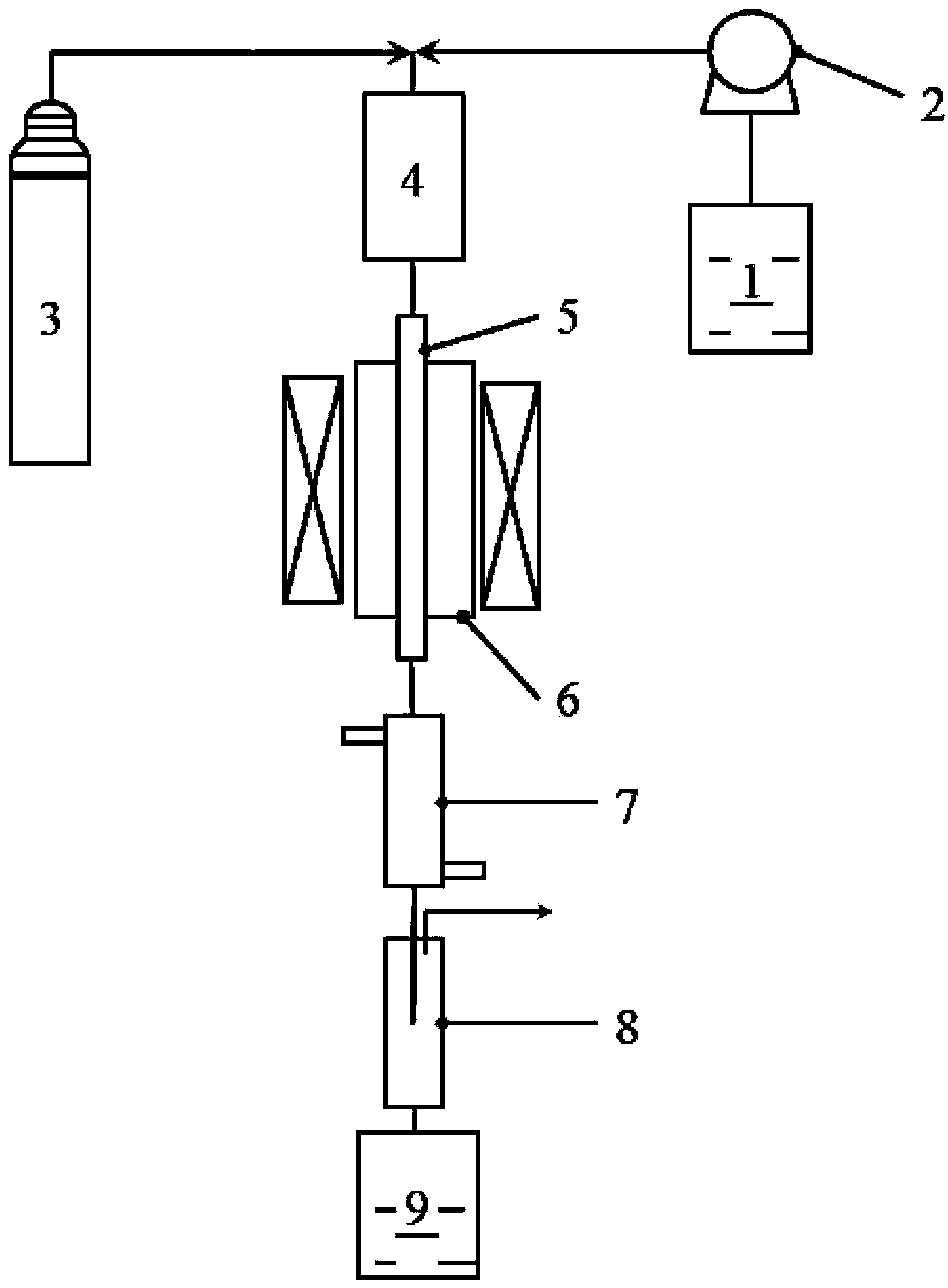

[0028] (2) Weigh 0.5 g of the above-mentioned reaction raw materials mixed with the catalyst and put them into the fixed-bed reactor 5, and tighten the joint of the fixed-bed reactor 5;

[0029] (3) Pass the carrier gas (nitrogen) into the fixed bed reactor 5, increase the system pressure to 0.5Mpa, and set the carrier gas flow rate to 0.5L / min;

[0030] (4) Set the temperature of the fixed bed reactor 5 to 160°C and the temperature of the vaporization chamber 4 to 160°C, and start to raise the temperature of the fixed bed reactor 5 and vaporization chamber 4;

[0031] (5) When the temperature of the vaporization chamber 4 and the fixed bed reactor 5 rises to the predetermined temperature respectively, water is supplied to the vaporization chamber 4 through the high-pressure advection pump 2, and the water flow rate is 0.5ml / min, and the water is vaporized in the vaporization chamber 4 to pr...

Embodiment 2

[0035] (1) Mechanically mix cellulose and potassium hydrogen sulfate according to the mass ratio of 5:1;

[0036] (2) Weigh 0.5 g of the above-mentioned reaction raw materials mixed with the catalyst and put them into the fixed-bed reactor 5, and tighten the joint of the fixed-bed reactor 5;

[0037] (3) Pass the carrier gas (argon gas) into the fixed bed reactor 5, increase the system pressure to 1.0Mpa, and set the carrier gas flow rate to 0.5L / min;

[0038] (4) Set the temperature of the fixed bed reactor 5 to 200°C, and the temperature of the vaporization chamber 4 to 200°C, and start to raise the temperature of the fixed bed reactor 5 and vaporization chamber 4;

[0039] (5) When the temperature of the vaporization chamber 4 and the fixed bed reactor 5 rises to the predetermined temperature respectively, water is supplied to the vaporization chamber 4 through the high-pressure advection pump 2, and the water flow rate is 1.0ml / min, and the water is vaporized in the vapori...

Embodiment 3

[0043] (1) Lithium hydrogen sulfate (mass ratio of lithium hydrogen sulfate to cellulose: 1:10) was loaded on the surface of cellulose by impregnation method, and dried at 70°C;

[0044] (2) Weigh 0.5 g of the above catalyst-loaded reaction raw materials into the fixed-bed reactor 5, and tighten the joint of the fixed-bed reactor 5;

[0045] (3) Pass the carrier gas (helium) into the fixed bed reactor 5, increase the system pressure to 2.0Mpa, and set the carrier gas flow rate to 0.3L / min;

[0046](4) Set the temperature of the fixed bed reactor 5 to 240°C, and the temperature of the vaporization chamber 4 to 240°C. When the temperatures of the vaporization chamber 4 and the fixed bed reactor 5 respectively rise to the predetermined temperature, the high pressure advection pump 2 will supply the vaporization chamber 4 with Water, the water flow rate is 1.5ml / min, the water is vaporized in the vaporization chamber 4 to produce water vapor and mixed with the carrier gas and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com