Active sulfur black dye and preparation method thereof

A technology of sulfur black and dyes, which is applied in the direction of organic dyes, can solve the problems of insufficient reactivity and limit the industrial application of dyes, and achieve the effect of improving solubility, improving coloring rate and dyeing performance, and meeting high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

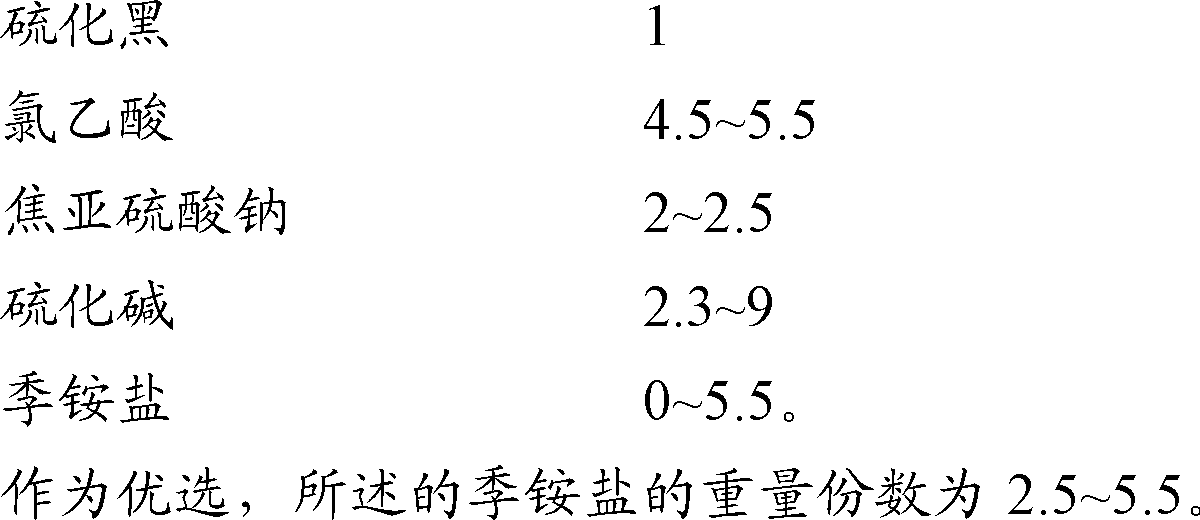

[0038] The raw material of the reactive sulfur black dye of the present embodiment comprises sulfur black and modifier, and modifier is made up of chloroacetic acid, sodium pyrosulfite, quaternary ammonium salt etc., the weight ratio of each component (sulfur black: chloroacetic acid: sodium pyrosulfite: Alkali sulfide: quaternary ammonium salt) is 1: 5.0: 2.5: 2.2: 1.5. The commercial brand of the used sulfur black is self-made UNIFIT sulfur black 200%.

[0039] The production process of reactive sulfur black dye includes the configuration of sulfur black solution, the configuration of modifier solution, the mixing process of sulfur black solution and modifier solution, drying, and pulverization; the configuration process of modifier solution includes chloroacetic acid The preparation of sodium solution and the configuration of sodium pyrosulfite aqueous solution, the configuration of sodium pyrosulfite aqueous solution is the same as the configuration method in the existing ...

Embodiment 2

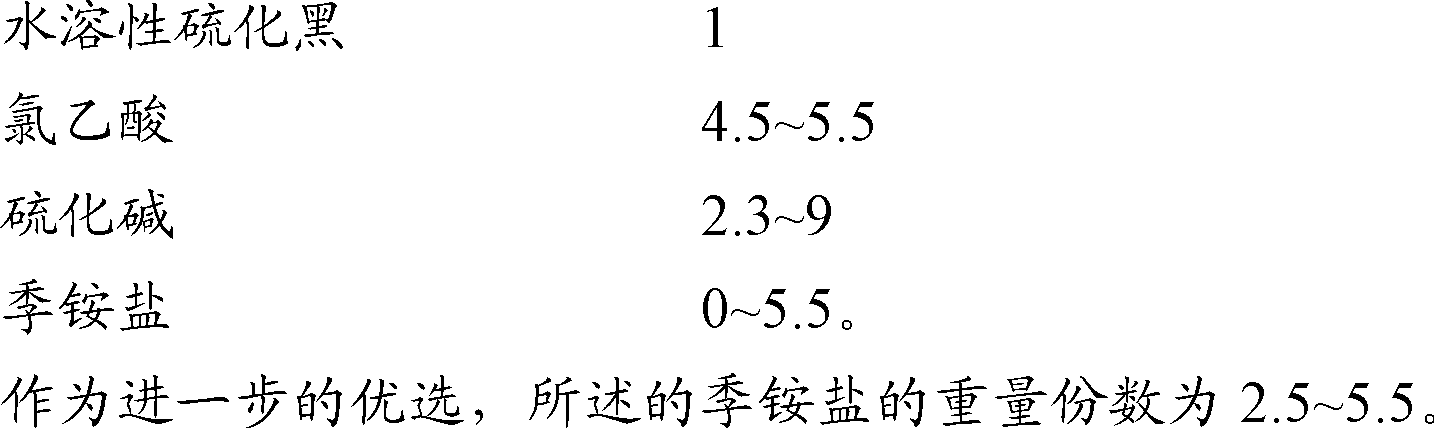

[0046] The raw material of reactive sulfur black dyestuff of this embodiment includes modified water-soluble sulfur black and special modifier, and modifier is made up of chloroacetic acid, sulfide alkali, caustic soda, quaternary ammonium salt, and the weight ratio of each component is water-soluble sulfur black The ratio of black: chloroacetic acid: sodium sulfide: quaternary ammonium salt is 1: 5.0: 2.0: 1.5, and the trade name of the water-soluble sulfur black used is UNIFIT. Its production process includes the configuration of water-soluble sulfur black solution, the configuration of modifier solution, the mixing reaction process of sulfur black solution and modifier solution, drying and crushing process. The specific process is as follows:

[0047] (1) Configuration of sulfur black solution: add an appropriate amount of water to the reaction kettle, and stir, add water-soluble sulfur black to the water, heat up to 85°C, add alkali sulfide, adjust the specific gravity of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dyeing rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com