Hard alloy with iron-nickel as binder metal and preparation method thereof

A technology for bonding metals and hard alloys, applied in the field of hard alloys and their preparation, can solve problems such as shortages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

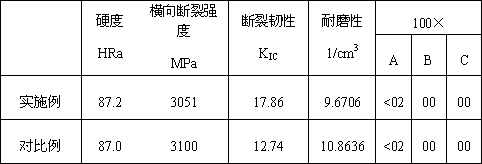

Examples

preparation example Construction

[0017] The preparation process of the cemented carbide with iron and nickel as the bonding metal is: firstly, WC powder and Fe-Ni alloy powder are wet-milled and mixed in a solvent. The solvent is alcohol, acetone, hexane, water or any combination of them. The mixture is then dried, shaped, and sintered.

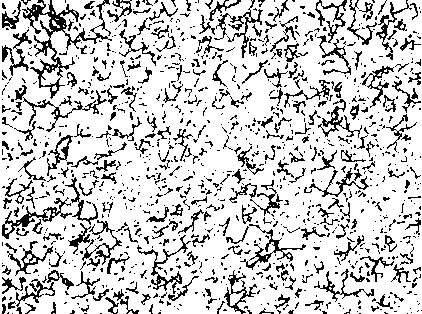

[0018] Use WC as the hard phase and 3-20% (weight ratio) Fe-Ni as the binder metal. The bonding metal is Fe-Ni alloyed metal, Fe and Ni are mixed at the atomic level, in which Fe accounts for 50-80%, and Ni is 20-50%. Fe-Ni alloy powder has good wettability to WC under vacuum liquid conditions, and the phase composition is face-centered cubic austenite and martensite (among which austenite is 65% and martensite is 35%), It is beneficial to ensure that the alloy has high strength while also having high toughness. In order to make the Fe-Ni alloy powder and WC powder easy to mix uniformly, the Fe-Ni alloy powder is made into a spherical shape with a particle size figure 2 , It...

Embodiment

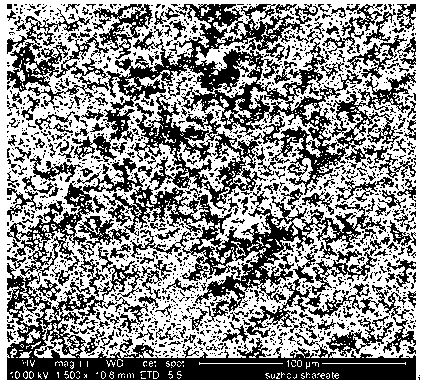

[0020] Ultrafine WC powder with a particle size of 1.0μm and Fe-Ni alloy powder with a particle size of 1.2μm are used (the morphology of the alloy powder is shown in the picture figure 1 ), according to the weight ratio WC: Fe-Ni = 9: 1 powder, the ball-to-battery ratio is 3.5:1, the grinding agent is alcohol, add 350ml per kilogram of powder, after 48 hours of ball milling, the powder is in Drying at a temperature of 120°C, the powder is mixed with forming agent after drying, and pressed into shape, and sintered at 1390°C for 60 minutes in a low-pressure (10MPa) sintering furnace integrated with mold release agent and sintering to make cemented carbide products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com