Device and method for balancing alumina concentration of aluminium electrolysis tank

An aluminum electrolytic cell and alumina technology, which is applied in the field of electrolytic aluminum, can solve problems such as the absence of materials with alumina concentration, unbalanced alumina consumption in anodic reactions, and limited service life of carbon anodes, so as to avoid excessively low alumina concentration , reduce the flicker effect, reduce the effect of anode side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

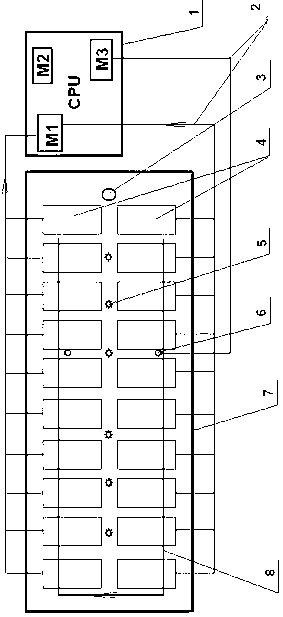

Embodiment 1

[0049]Install the anode current density monitoring module M1, the alumina concentration estimation module M2 and the alumina small cutting control module M3 in the CPU of the 300KA series (20 sets of double anode) electrolytic cell control system; the M1 module continuously performs the anode equidistant pressure drop Measurement, anode current calculation, anode current density calculation and other operations, and then report the anode current density data to the CPU; the CPU analyzes the anode current density and finds that the current density at the anodes A4 and A16 is high, and the CPU starts the alumina concentration estimation module M2 to Estimate the alumina concentration at the anodes A4 and A16, if the alumina concentration at the anodes A4 and A16 is low, the CPU will issue a small cutting command to the M3 module, and the M3 module will move the small feeder 6 to the anodes A4 and A16 , according to the amount of alumina determined by the CPU, perform a small blan...

Embodiment 2

[0051] Install the anode current density monitoring module M1, the alumina concentration estimation module M2 and the alumina small cutting control module M3 in the CPU of the 300KA series (20 sets of double anode) electrolytic cell control system; the M1 module continuously performs the anode equidistant pressure drop Measurement, anode current calculation, anode current density calculation and other operations, and then report the anode current density data to the CPU; the CPU analyzes the anode current density and finds that the current density at A7 of the newly replaced anode is low, and the CPU starts the alumina concentration estimation module M2 to The alumina concentration at the anode A7 is estimated. If the alumina concentration at the anode A7 is too high, the CPU will issue an instruction to reduce the feeding to the intermediate feeder 5 near the anode A7. After that, the CPU starts the M2 module to estimate the alumina concentration again. And confirm whether the...

Embodiment 3

[0053] Install the anode current density monitoring module M1, the alumina concentration estimation module M2 and the alumina small cutting control module M3 in the CPU of the 350KA series (48 groups of single anode) electrolytic cell control system; the M1 module continuously implements the anode equidistant pressure drop Perform operations such as measurement, anode current calculation, and anode current density calculation, and then report the anode current density data to the CPU. The CPU analyzes the anode current density and finds that the current density at the anodes A21, A22, and A35 is relatively high, and the CPU starts the alumina concentration estimation module. M2 estimates the alumina concentration at the anodes A21, A22 and A35, if the alumina concentration at the anodes A21, A22 and A35 is low, the CPU will issue a small cutting command to the M3 module, and the M3 module will move the small feeding device 6 To the anodes A21 and A35, carry out a small blanking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com