System and method for efficiently and economically processing coal ash and bottom slag of coal-fired units of power plants

A coal-fired unit and processing device technology, applied in the direction of combustion method, removal of solid residue, treatment of combustion products, etc., to achieve the effect of ensuring uniformity, good uniformity, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0032] Example.

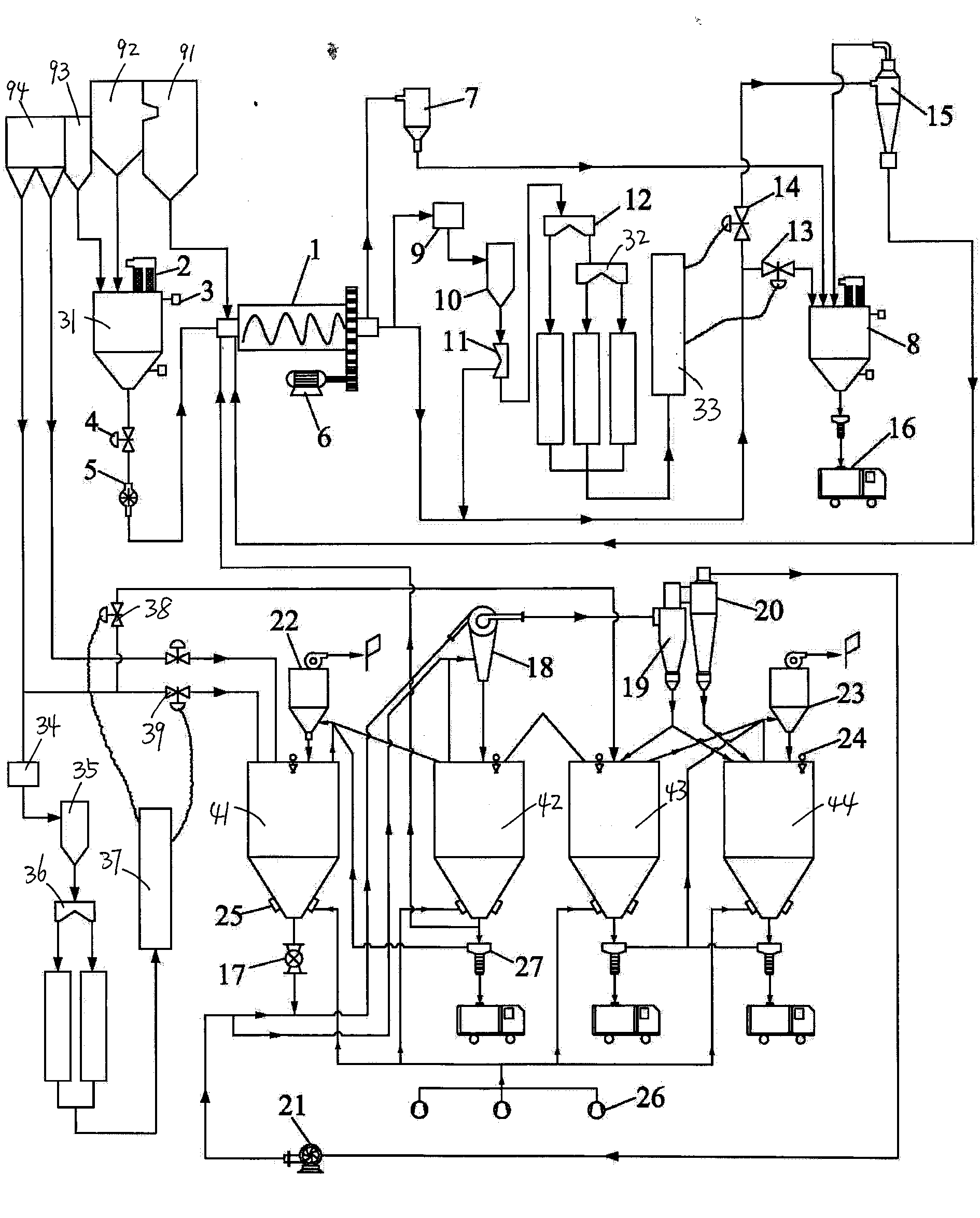

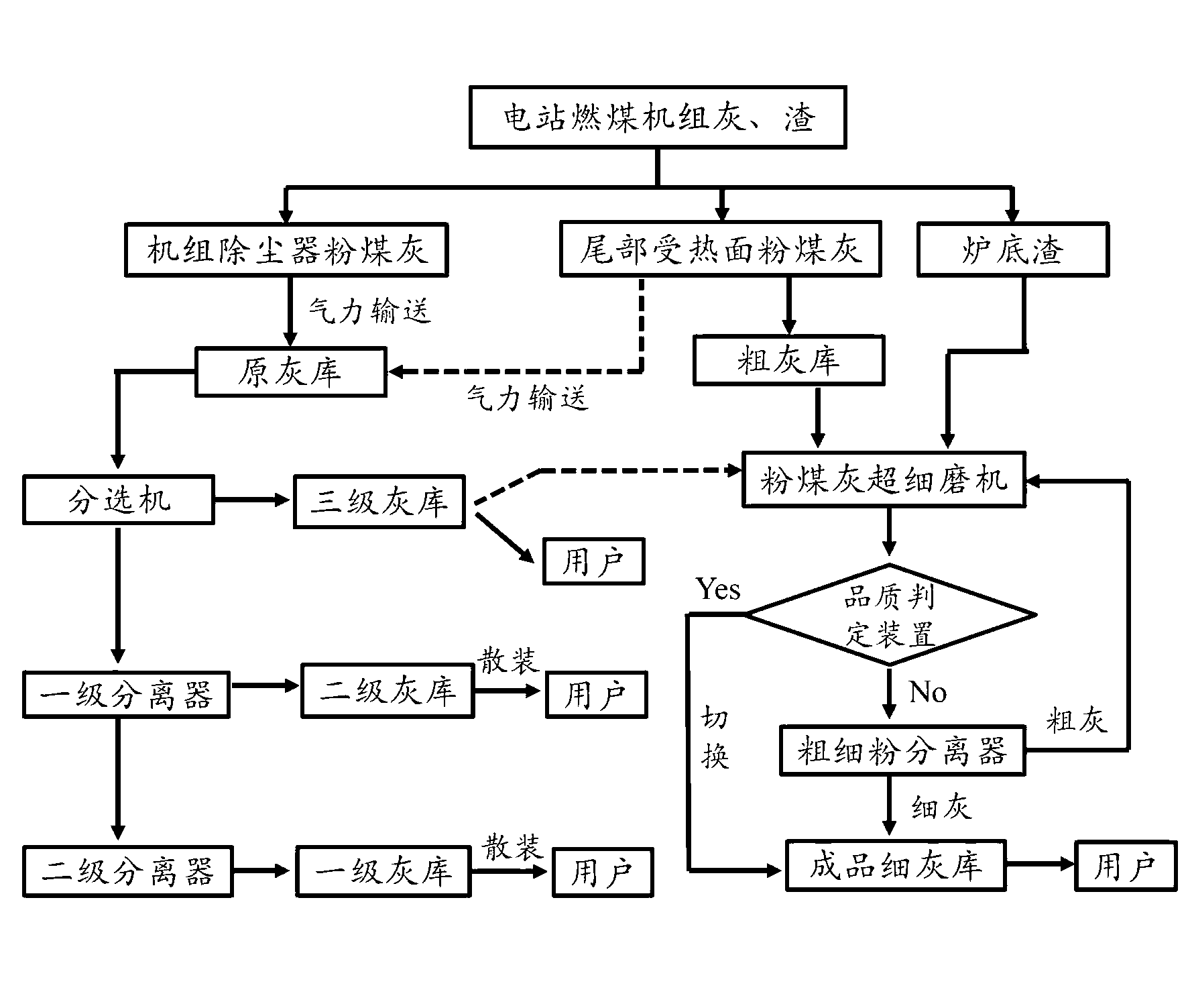

[0033] see Figure 1 to Figure 2 , the high-efficiency and economical processing device for fly ash and furnace bottom slag of the coal-fired unit of the power station in this embodiment includes a coarse ash storehouse 31 connected with an economizer 92 and an air preheater 93 on the heating surface of the boiler tail, installed in the coarse ash storehouse 31 Coarse ash storehouse deduster 2 and coarse ash storehouse material level indicating device 3 on the upper, fly ash superfine mill 1 connected with power station coal-fired unit pulverized coal furnace 91 and coarse ash storehouse 31, installed in coarse ash storehouse 31 and Coarse ash storage pneumatic gate valve 4 and lifting device betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com