Method of determining polyether polyol content in drilling fluid in field

A polyether polyol and drilling fluid technology, which is applied in the measurement of color/spectral characteristics, etc., can solve the problems of small detection range, cumbersome steps, complicated operation, etc., and achieves low cost, simple and fast analysis process, and good reproducibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

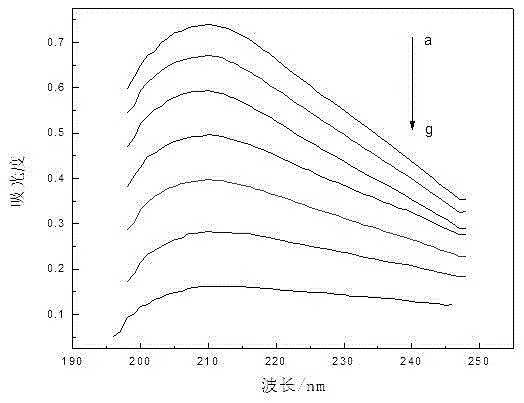

[0022] 1. Drawing of linear relationship standard curve:

[0023] 1. Accurately weigh 7 parts of 15g drilling fluid in a 250mL volumetric flask, add different quality polyether polyol standard samples, so that the polyether polyol mass fractions are 0, 0.3495%, 0.7006%, 1.025%, 1.431% , 1.873%, 2.294%, dilute to 250mL with deionized water. Dilute 5 times with deionized water for later use.

[0024] 2. Take seven 5mL centrifuge tubes, add 3.5mL of the above-mentioned 7 parts of standard polyether polyol drilling fluid, and then add a drop of hydrochloric acid aqueous solution (V HCl :V H2O =1:4), so that the pH of the mixed system in the 7 centrifuge tubes was 2. Add 1 mL of barium chloride with a mass percentage of 30% to each of the seven centrifuge tubes for reaction, and then add 100.00 μl of a 5% mass percentage of silicomomolybdic acid aqueous solution to the seven centrifuge tubes after the reaction The reaction was carried out, and after the reaction was completed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com