Warehousing quantification and conveying control method of cement production resource comprehensive utilization

A technology of production resources and control methods, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problem of lack of accurate quantitative and alarm systems, inability to integrate and utilize waste, and can only be used in preheaters after grinding. Some of them need to be processed and directly sprayed into the decomposition furnace and rotary kiln after drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

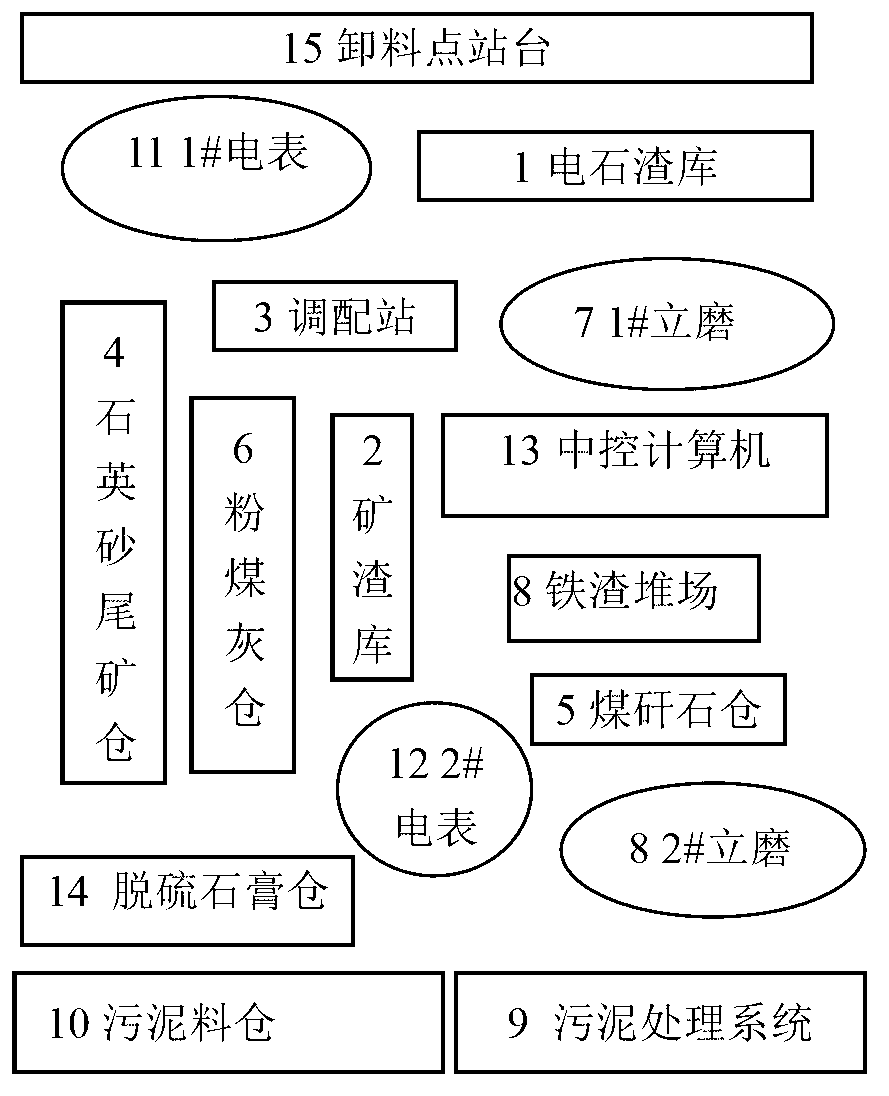

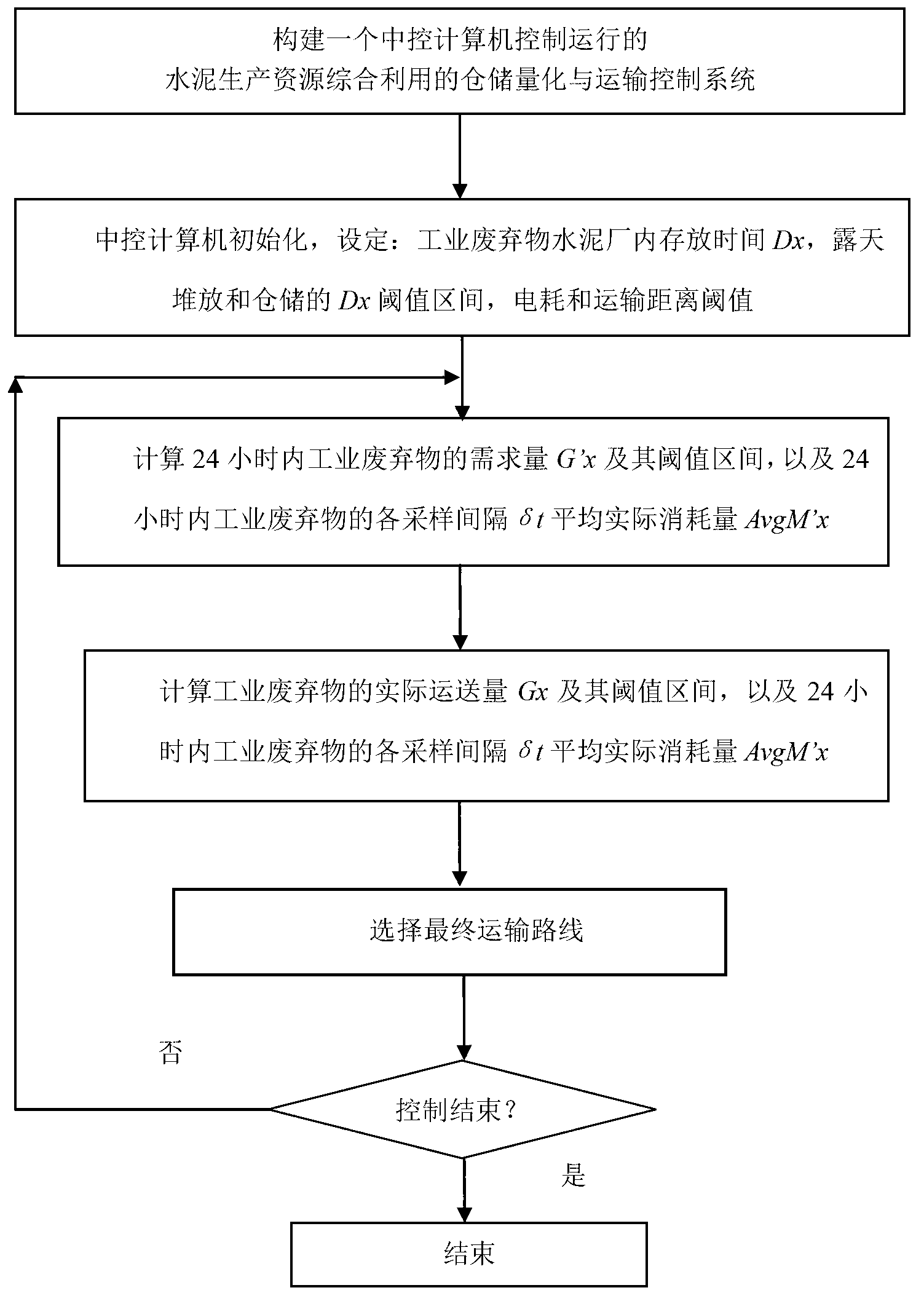

[0085] According to the accompanying drawings in the following figure 1 and figure 2 , and the embodiment further illustrates the invention.

[0086] Such as figure 1 and figure 2 As shown, construct a warehousing quantification and transportation control system for the comprehensive utilization of cement production resources controlled by the central control computer, initialize the central control computer,

[0087] The design scale of the cement production line in the embodiment is 2000t clinker / day, and the actual output is 2400t clinker / day.

[0088] These include the establishment of the following quantitative storage units in the area of the cement plant, that is, storage yards and silos: calcium carbide slag warehouses, iron slag storage yards, quartz sand tailings warehouses, slag storage yards, coal gangue pre-homogenization storage yards, powder Coal ash silos, desulfurized gypsum silos and sludge silos, of which:

[0089] Carbide slag warehouse, storing in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com