Groove MOS (metal oxide semiconductor) structure Schottky diode and preparation method thereof

A technology of Schottky diode and MOS structure, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems that cannot be applied in high-voltage environment, fast turn-on and turn-off speed, low forward turn-on voltage, etc., to achieve The effect of compact product structure, reduced production cycle, and reduced process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

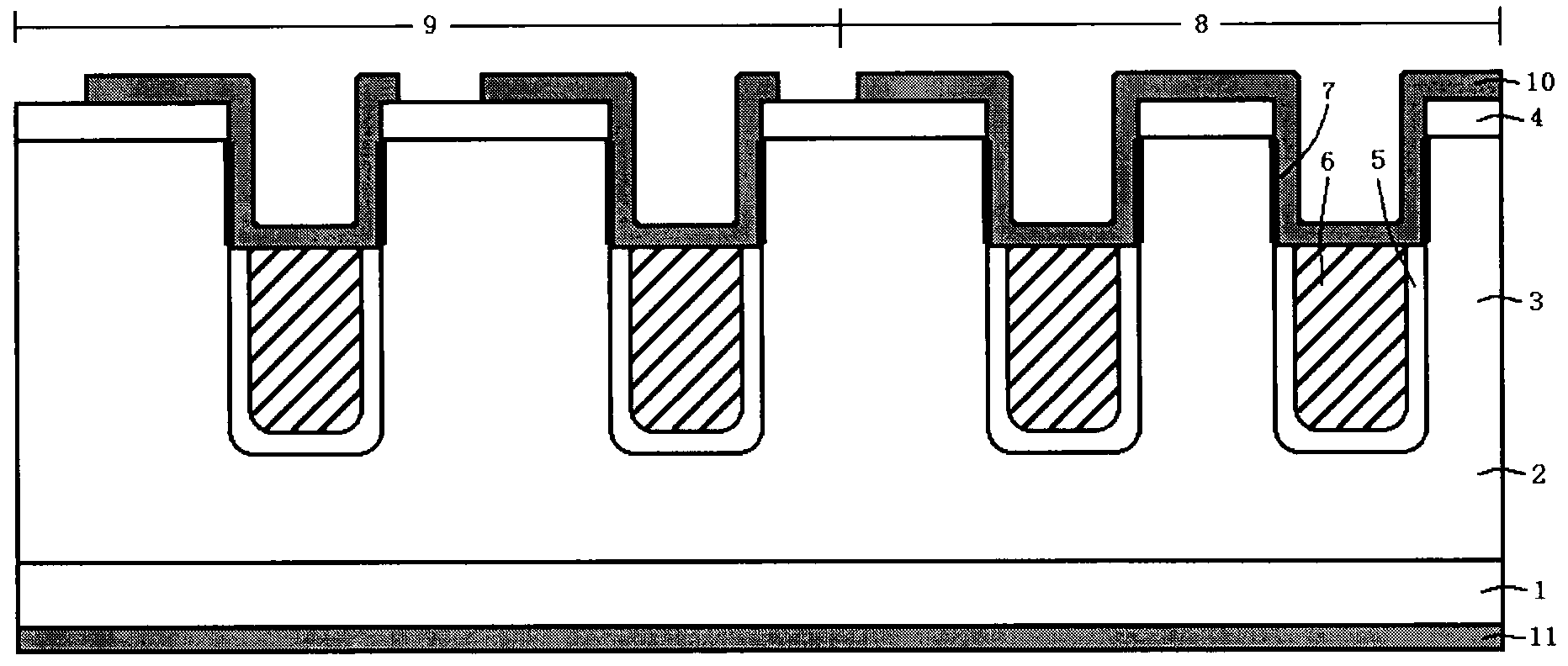

[0027] figure 1 Be a kind of trench MOS structure Schottky diode of the present invention, combine below figure 1 The semiconductor device of the present invention will be described in detail.

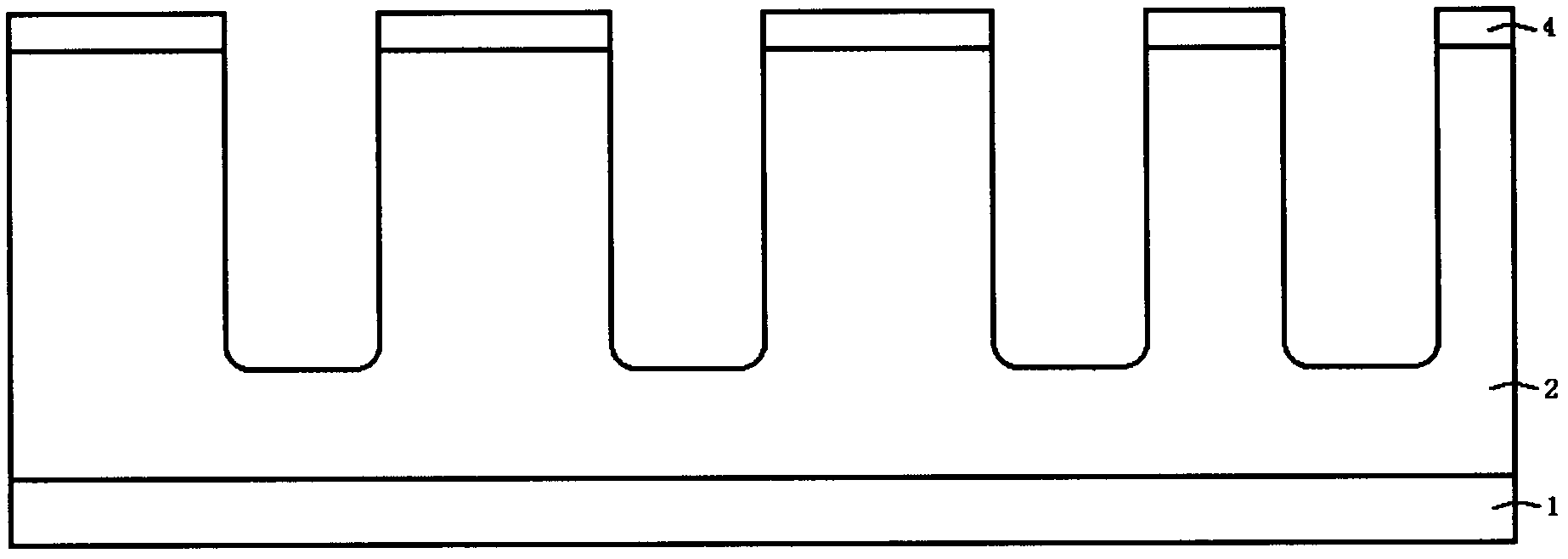

[0028] A Schottky diode with a trench MOS structure, comprising: a substrate layer 1, which is an N-conductive semiconductor silicon material, on the lower surface of the substrate layer 1, an electrode is drawn out through a metal layer 11 on the lower surface; a drift layer 2, located on the substrate layer 1 The upper part is a semiconductor silicon material of N conductivity type; the drift layer trench region 3 is located on the upper part of the drift layer 2; the thermal oxidation layer 4 is located on the upper surface of the drift layer 2 and is an oxide of semiconductor silicon material; the vertical trench is located in the silicon body, A gate oxide layer 5 is grown on its inner wall, the trench is filled with gate polysilicon 6, and there is a Schottky barrier junction 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com