Preparation method of synthetic graphite and application thereof

A technology of artificial graphite and graphitization treatment, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of difficult to meet the application requirements of lithium-ion batteries, high production costs and energy consumption, cumbersome preparation process, etc., and achieve compatibility effects Good, cost saving, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

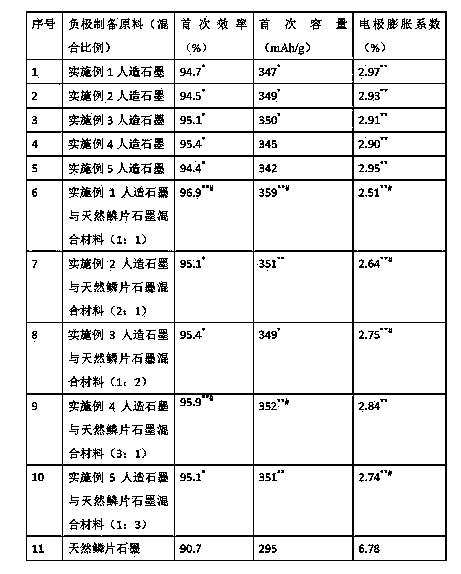

Examples

Embodiment 1

[0020] Embodiment 1 The preparation method of artificial graphite of the present invention

[0021] Using asphalt as raw material, put the asphalt into the reactor, control the temperature at 350°C and polymerize at a stirring rate of 1000r / min for 24 hours to obtain mesophase pitch, and the polymerization pressure is 4.5Mpa; carbonize the mesophase pitch at 600°C Treatment: the carbonized mesophase pitch is subjected to graphitization treatment at 3000° C. for 3 hours to obtain the artificial graphite of the present invention.

Embodiment 2

[0022] The preparation method of embodiment 2 artificial graphite of the present invention

[0023] Using asphalt as raw material, put the asphalt into the reactor, control the temperature at 380°C and polymerize at a stirring rate of 600r / min for 20 hours to obtain mesophase pitch, and the polymerization pressure is 3Mpa; carbonize the mesophase pitch at 700°C ; The carbonized mesophase pitch is graphitized at 2900° C. for 3 hours to obtain the artificial graphite of the present invention.

Embodiment 3

[0024] The preparation method of embodiment 3 artificial graphite of the present invention

[0025] Using asphalt as raw material, put the asphalt into the reactor, control the temperature at 400°C and polymerize at a stirring rate of 700r / min for 17 hours to obtain mesophase pitch, and the polymerization pressure is 3Mpa; carbonize the mesophase pitch at 900°C ; The artificial graphite of the present invention can be obtained by graphitizing the carbonized mesophase pitch at 2850°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com