Preparation method of graphene/titanium dioxide photocatalyst

A titanium dioxide and photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as difficulty in dispersion, avoid agglomeration, reduce the chance of impurities, and react quickly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of preparation method of graphene / titanium dioxide photocatalyst, comprises the steps:

[0028] (1) To prepare solution A, slowly add 0.07 g of tetrabutyl titanate to 40 mL of chloroform at a concentration of 1.75 g / L; to prepare solution B, add 0.024 g of graphene oxide prepared by the Hummers method to 40 mL In the mixture of deionized water and ethanol, the concentration of graphene oxide was 0.6 g / L. The obtained mixed solution B was added dropwise into the solution A while stirring, and stirred evenly to obtain a mixed solution of A and B.

[0029] (2) Put the mixed solution of A and B into a hydrothermal kettle and keep it warm at 180°C for 12 hours; after natural cooling to room temperature, separate and wash to obtain a graphene / titanium dioxide photocatalyst with excellent photocatalytic performance.

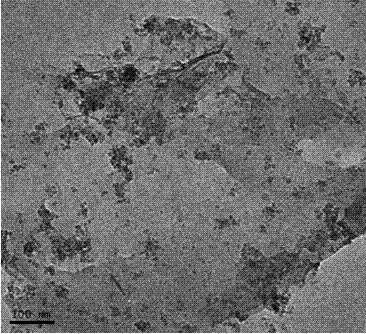

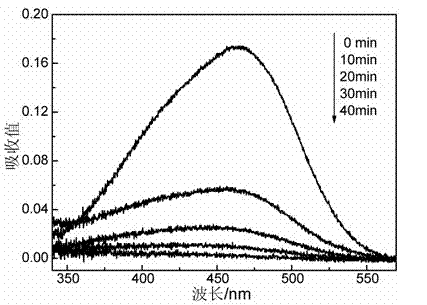

[0030] Through transmission electron microscopy analysis, it can be seen that titanium dioxide nanoparticles are dispersed on graphene sheets, such as f...

Embodiment 2

[0032] A kind of preparation method of graphene / titanium dioxide photocatalyst, comprises the steps:

[0033] (1) To prepare solution A, slowly add 0.17 g of tetrabutyl titanate to 40 mL of chloroform at a concentration of 4.2 g / L; to prepare mixed solution B, add 0.008 g of graphene oxide prepared by the Hummers method to 40 mL In the mixed solution of deionized water and ethanol, the concentration of graphene oxide was 0.02 g / L. Add the mixed solution B dropwise to the solution A while stirring, and continue to stir and mix evenly to obtain a mixed solution of A and B.

[0034] (2) Put the mixed solution of A and B into a hydrothermal kettle and keep it warm at 160°C for 20 hours; after natural cooling to room temperature, separate and wash to obtain a graphene / titanium dioxide photocatalyst with excellent photocatalytic performance.

Embodiment 3

[0036] A kind of preparation method of graphene / titanium dioxide photocatalyst, comprises the steps:

[0037] (1) To prepare solution A, slowly add 0.034 g of tetrabutyl titanate to 40 mL of chloroform at a concentration of 0.85 g / L; to prepare mixed solution B, add 0.032 g of graphene oxide prepared by the Hummers method to 40 mL In the mixed solution of deionized water and ethanol, the concentration of graphene oxide was 0.8 g / L. The obtained mixed solution B was added dropwise into the solution A while stirring, and stirred evenly to obtain a mixed solution of A and B.

[0038] (2) Put the mixed solution of A and B into a hydrothermal kettle and keep it warm at 200°C for 5 hours; after natural cooling to room temperature, separate and wash to obtain a graphene / titanium dioxide photocatalyst with excellent photocatalytic performance.

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com