Silver-coated cobalt powder and preparation method thereof

A technology of silver-coated cobalt powder and cobalt salt, which is applied in the direction of coating, etc., can solve the problems of low reduction efficiency, difficult kinetics, and inability to obtain pure cobalt powder, and achieve high production efficiency, simple process, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

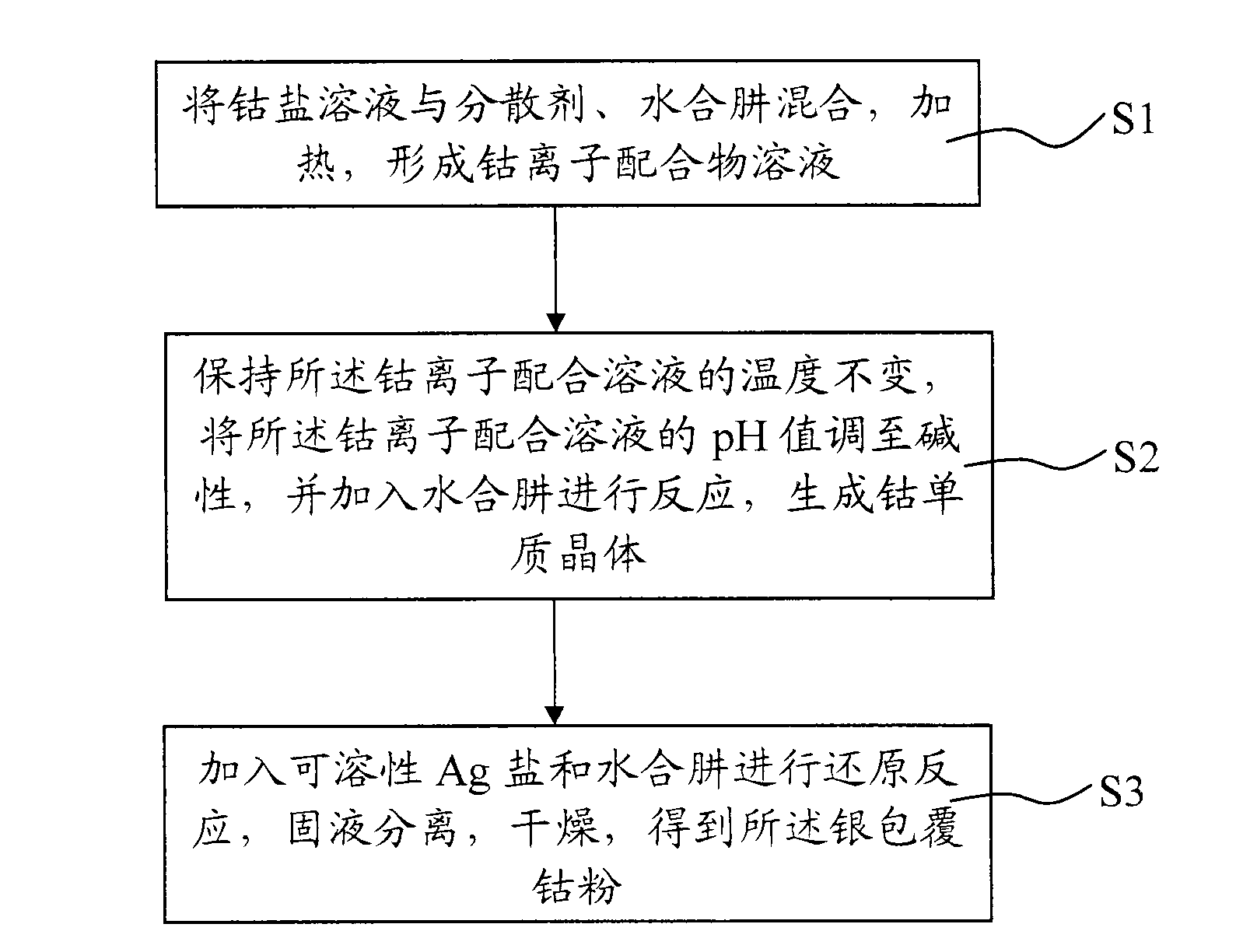

[0023] The embodiment of the present invention provides a method for preparing silver-coated cobalt powder by adding hydrazine hydrate step by step, which is simple in process, easy to control, low in cost, and suitable for industrial production. The technological process of this silver-coated cobalt powder preparation method is as follows figure 1 shown, including the following steps:

[0024] S1: Mix the cobalt salt solution with the dispersant and hydrazine hydrate, and heat to form a cobalt ion complex solution; the molar ratio of the hydrazine hydrate to the cobalt salt is 1.3-1.5:1;

[0025] S2: keep the temperature of the cobalt ion complex solution constant, adjust the pH value of the cobalt ion complex solution to alkaline, and add hydrazine hydrate to react to generate cobalt elemental crystals; then

[0026] S3: adding soluble Ag salt and hydrazine hydrate to carry out reduction reaction, separating solid and liquid, and drying to obtain the silver-coated cobalt po...

Embodiment 1

[0038] A silver-coated cobalt powder, the preparation method of which is as follows:

[0039] S11: First CoCl 2 ·6H 2 The O solution was mixed with sodium hypophosphite for 30 minutes, then heated to 83°C, and then hydrazine hydrate was added for mixing to form Co 2+ Complex solution; among them, hydrazine hydrate and CoCl 2 ·6H 2 The molar ratio of O is 1.4:1, CoCl 2 ·6H 2 The mol ratio of O and sodium hypophosphite is 1: 1.3;

[0040] S12: Keep the Co 2+ The temperature of the complex solution remains unchanged (83° C.), the pH value of the cobalt ion complex solution is adjusted to pH=12, and hydrazine hydrate is added to react to form cobalt elemental crystals, wherein the hydrazine hydrate and cobalt ion complex The molar ratio of cobalt ions in the medium is 2.5:1;

[0041] S13: at a temperature of 83°C, add silver nitrate and hydrazine hydrate for a reduction reaction for 50 minutes, filter, and dry to obtain the silver-coated cobalt powder, wherein the amount o...

Embodiment 2

[0045] A silver-coated cobalt powder, the preparation method of which is as follows:

[0046] S21: CoSO 4 The solution was mixed with sodium hypophosphite for 20 minutes, then heated to 80°C, and then added with hydrazine hydrate for mixing to form Co 2+ Complex solution; among them, hydrazine hydrate and CoSO 4 The molar ratio is 1.3:1, CoSO 4 The molar ratio to sodium hypophosphite is 1:1.5;

[0047] S22: keep the Co 2+ The temperature of the complex solution remains unchanged (80° C.), the pH value of the cobalt ion complex solution is adjusted to pH=13, and hydrazine hydrate is added to react to form cobalt elemental crystals, wherein the hydrazine hydrate and cobalt ion complex The molar ratio of cobalt ions in the medium is 3:1;

[0048] S23: at a temperature of 80°C, add silver nitrate and hydrazine hydrate for a reduction reaction for 60 minutes, filter, and dry to obtain the silver-coated cobalt powder, wherein the amount of silver nitrate added is 10% of the mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com