Production method of acid calcium pyrophosphate for food leavening agent

A technology of calcium pyrophosphate and production methods, applied in chemical instruments and methods, applications, food science, etc., can solve the problems of no production process, etc., and achieve the effect of convenient process, strong operability and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

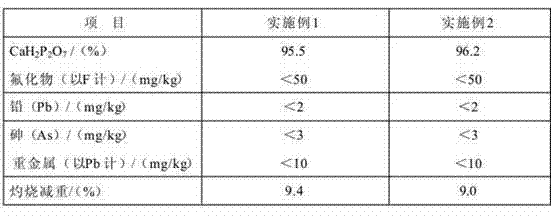

Examples

Embodiment 1

[0012] Add 1000kg phosphoric acid (85% H 3 PO 4 ), slowly and continuously add 1732kg lime milk (18% Ca(OH) 2 ), the reaction temperature is about 70°C, and the reaction is about 1h. The slurry obtained by the reaction is sent to the spray drying tower for drying. The inlet temperature is 550°C, and the outlet temperature is 110°C. The dried powder is sent to the polymerization furnace for polymerization. The polymerization temperature is controlled at At about 260°C, control the partial pressure of water vapor to 5.0Mpa, and react for about 2 hours to obtain the acid calcium pyrophosphate product, which is used as a food leavening agent.

[0013] The whole reaction process equation is:

[0014] Ca(OH) 2 ﹢2H 3 PO 4 → Ca(H 2 PO 4 ) 2 ﹢2H 2 O;

[0015] Ca(H 2 PO 4 ) 2 → CaH 2 P 2 o 7 + H 2 O.

Embodiment 2

[0017] Add 1000kg phosphoric acid (75% H 3 PO 4 ), slowly and continuously add 500kg of milk of limestone (45% CaCO 3 ), the reaction temperature is about 80°C, the reaction is about 0.5h, and then continue to add 575kg lime milk (20% Ca(OH) 2 ), the reaction temperature is about 65°C, and the reaction is about 1h. The slurry obtained from the reaction is sent to a spray drying tower for drying. The inlet temperature is 600°C and the outlet temperature is 125°C. The dried powder is sent to a polymerization furnace for polymerization. The polymerization temperature is controlled at about 280°C, and the water vapor partial pressure is controlled at 6.0Mpa. After reacting for about 2 hours, an acid calcium pyrophosphate product is obtained, and the acid calcium pyrophosphate is used as a food leavening agent.

[0018] The whole reaction process equation is:

[0019] CaCO 3 + 2H 3 PO 4 → Ca(H 2 PO 4 ) 2 + H 2 O + CO 2 ;

[0020] Ca(OH) 2 + 2H 3 PO 4 → C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com