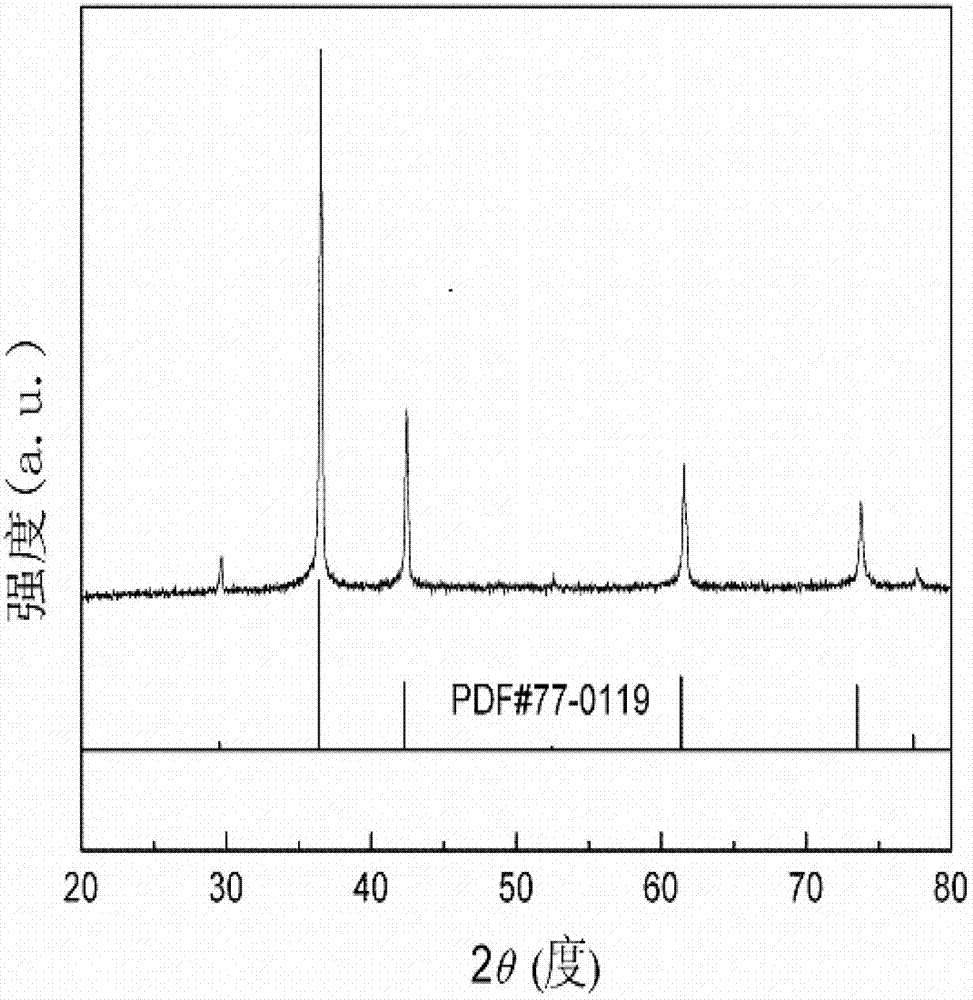

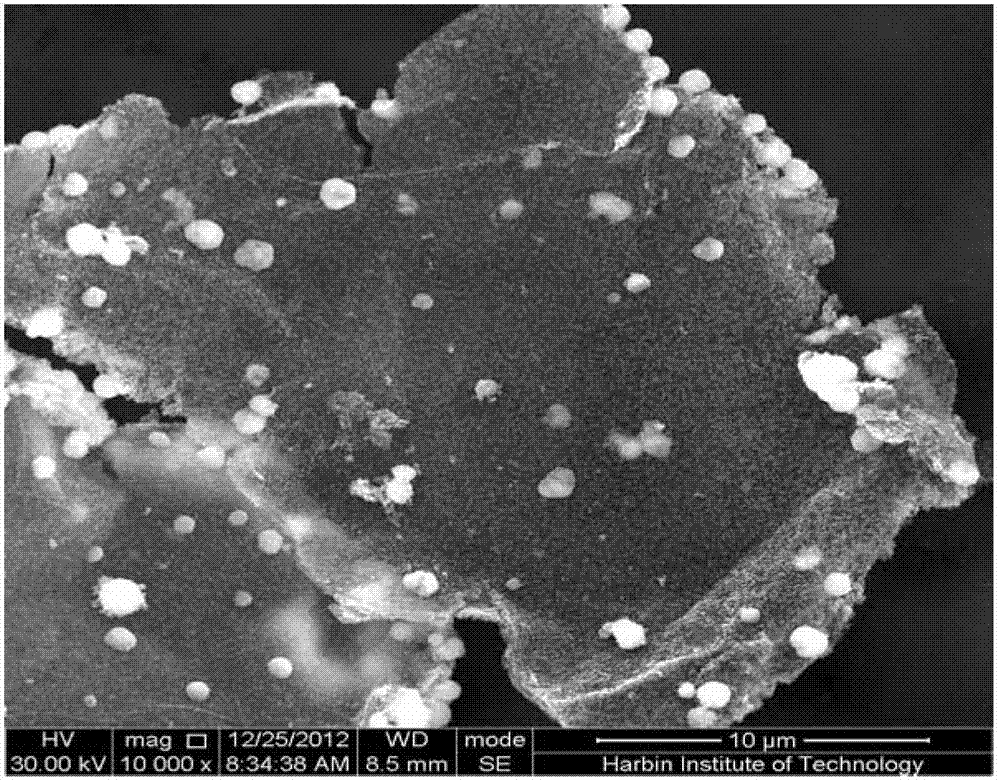

Preparation method for cuprous oxide/reduced graphene oxide composite functional material

A graphene composite, cuprous oxide technology, applied in copper oxide/copper hydroxide, graphene, nanotechnology for materials and surface science, etc., can solve the problems of environmental pollution, complex synthesis process, etc. Contamination-free, high purity, mild effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0010] Embodiment 1: The preparation method of a cuprous oxide / reduced graphene oxide composite functional material of this embodiment is carried out through the following steps: 1. First, weigh graphite oxide, add water, and disperse by ultrasonic for 0.5-1.5 h Then the concentration is 0.008~0.012g·ml -1 Graphene oxide dispersion liquid A; Two, take by weighing copper salt and glucose, be dissolved in deionized water, obtain the mixed solution B of copper salt and glucose, wherein the mol ratio of copper salt and glucose is 1: (0.5~0.8), The final concentration of copper salt is 0.4~0.62mol·L -1 , the final concentration of glucose is 0.2~0.48mol·L -1 3. Weigh the alkali and dissolve it in deionized water to obtain a concentration of 0.8-1.8 mol·L -1 Alkaline solution C; 4. Under the condition that the dispersion liquid A of graphene oxide is still, add the mixed solution B dropwise, and let stand for 25~35min to obtain the mixed solution D, wherein the dispersion liquid A...

specific Embodiment approach 2

[0012] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the copper salt in step 2 is copper acetate monohydrate, copper sulfate pentahydrate, trihydrate and copper nitrate or copper chloride dihydrate. Others are the same as the first embodiment.

specific Embodiment approach 3

[0013] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the alkali in step 3 is sodium hydroxide or potassium hydroxide. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com