Method of recovering Pb<2+> from electrolytic zinc rinsing waste water by using manganese oxide modified diatomite

A technology of diatomite and manganese oxide, applied in chemical instruments and methods, metallurgical wastewater treatment, water/sewage treatment, etc., can solve the problems of small adsorption capacity of diatomite, and achieve the effect of high recovery rate and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

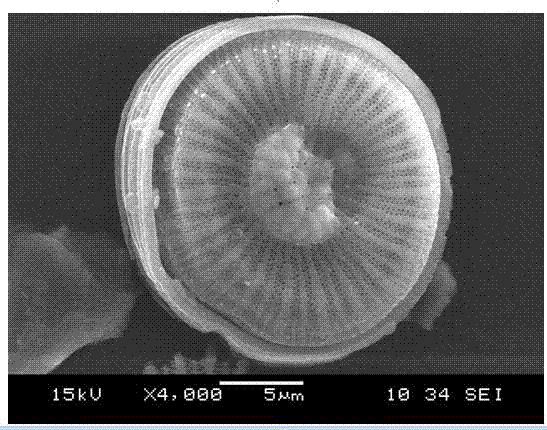

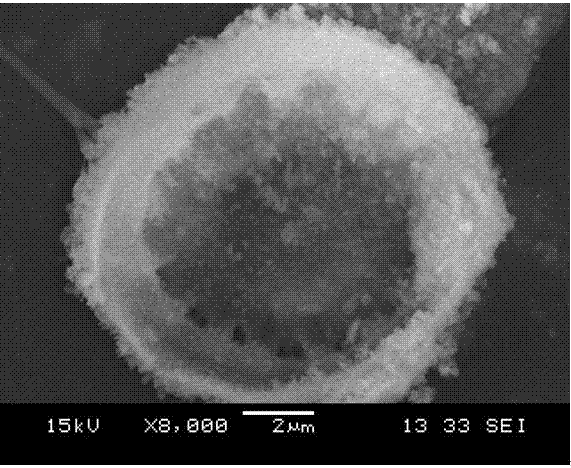

Image

Examples

Embodiment

[0016] (1) Take 15g of purified diatomaceous earth and add it to 50 mL of NaOH solution with a concentration of 4mol / L, shake at 90°C for 100 minutes, then remove the upper layer solution, and then add 100mL of MnCl with a concentration of 2mol / L 2 The solution was adjusted to pH 1.5 with analytical pure HCl, left to stand for 120 minutes, stirred for 60 minutes, then left to stand for 24 hours, and the supernatant was removed.

[0017] (2) Add 25 mL of MnCl with a concentration of 2 mol / L to the resultant of step (1) 2 The solution was stirred and allowed to stand.

[0018] (3) Repeat the operation process of step (2), remove the supernatant, wash with pure water until neutral, centrifuge to separate the solid from the liquid, take the solid and dry it at 105°C, crush it through a 200-mesh sieve, and prepare the adsorbent Manganese oxide modified diatomaceous earth.

[0019] (4) Put 0.1g of the adsorbent manganese oxide modified diatomite obtained in step (3) into a 250mL c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com