Nano-modification waterborne polyurethane pressure-sensitive adhesive for protective film and preparation method of nano-modification waterborne polyurethane pressure-sensitive adhesive

A water-based polyurethane, nano-modified technology, applied in fibrous fillers, adhesive additives, dyed organosilicon compound treatment, etc., to achieve the effect of excellent temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

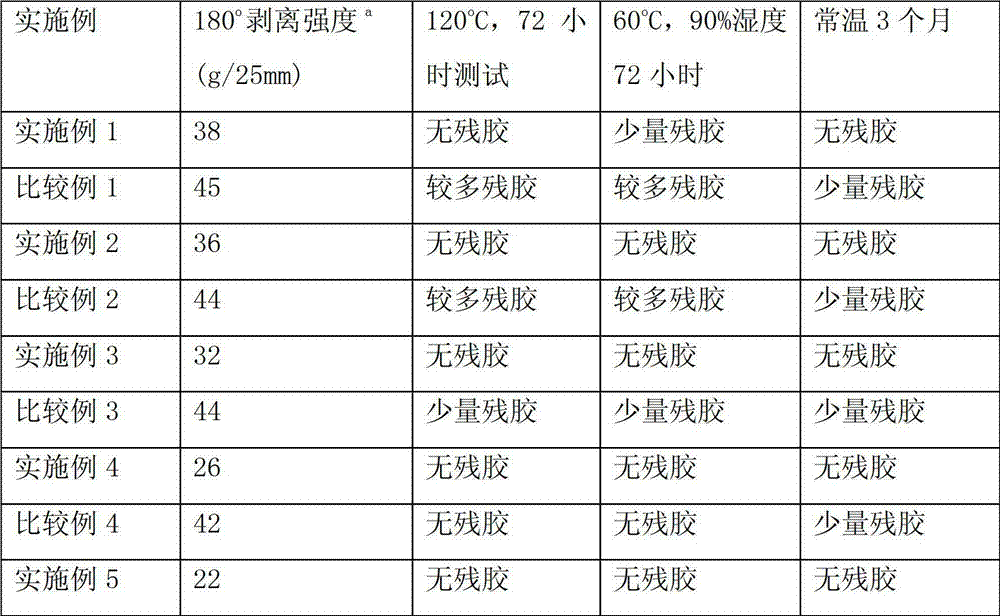

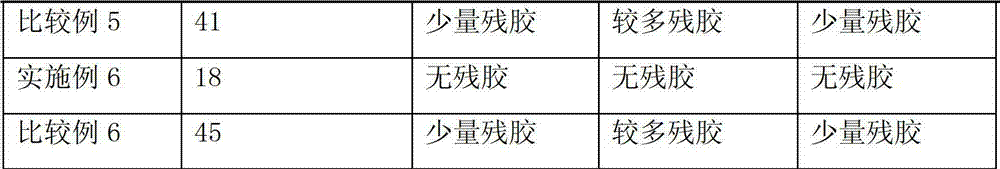

Examples

Embodiment 1

[0042] 1. Preparation of nano-modified TiO 2 :

[0043] 50g nano TiO 2 (particle size of 100nm) was dispersed in 2.4kg of toluene, ultrasonically dispersed for 10 minutes, added 35g ethyltrimethoxysilane, 2.5g triethylamine, reflux reaction at 120°C for 5 hours, filtered after the reaction, and used anhydrous Washed with ethanol and dried in a vacuum oven for 24 hours to obtain nano-modified TiO 2 .

[0044] 2. Preparation of nano-modified water-based pressure-sensitive adhesive:

[0045] 100g of polyoxypropylene diol (molecular weight 1000), 23.3g of isophorone diisocyanate, 0.2g of triethylamine, 0.5g of dimethylol propionic acid and 0.6g of diethylene glycol were stirred and mixed, under nitrogen protection Raise the temperature to 90°C and react for 2 hours, then cool down to 40°C after fully reacting and add nano-modified TiO 2 . 2g, 0.8g of sodium polyacrylate and 350g of distilled water, fully stir the mixed solution until uniform and keep it warm for 1 hour, afte...

Embodiment 2

[0049] 1. Preparation of nano-modified TiO 2 :

[0050] The method is the same as in Example 1.

[0051] 2. Preparation of nano-modified water-based pressure-sensitive adhesive:

[0052] Stir and mix 100 g of polyethylene glycol (molecular weight 1000), 23.3 g of isophorone diisocyanate, 0.15 g of triethylamine, 0.4 g of dimethylol propionic acid and 0.5 g of diethylene glycol, and heat up under nitrogen protection React at 90°C for 2 hours, cool down to 40°C after fully reacting and add nano-modified TiO 2 3g, 0.6g of sodium polyacrylate and 350g of distilled water, fully stir the mixed solution until uniform and keep it warm for 1 hour, after cooling, the pressure-sensitive adhesive solution is obtained.

Embodiment 3

[0056] 1. Preparation of nano-modified TiO 2 :

[0057] The method is the same as in Example 1.

[0058] 2. Preparation of nano-modified water-based pressure-sensitive adhesive:

[0059] 100g of polyoxypropylene diol (molecular weight 1000), 17.6g of hexamethylene diisocyanate, 0.2g of triethylamine, 0.4g of dimethylol propionic acid and 0.5g of diethylene glycol were stirred and mixed, under nitrogen protection Raise the temperature to 90°C and react for 2 hours, then cool down to 40°C after fully reacting and add nano-modified TiO 2 3g, 0.7g of sodium polyacrylate and 350g of distilled water, stir the mixture until uniform and keep it warm for 1 hour, after cooling, the pressure-sensitive adhesive solution is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com