Sludge thermal drying dry silo safety control system

A technology of safety control and dry silo, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of difficult guarantee of safety and reliability, and achieve complete monitoring data, perfect system structure and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

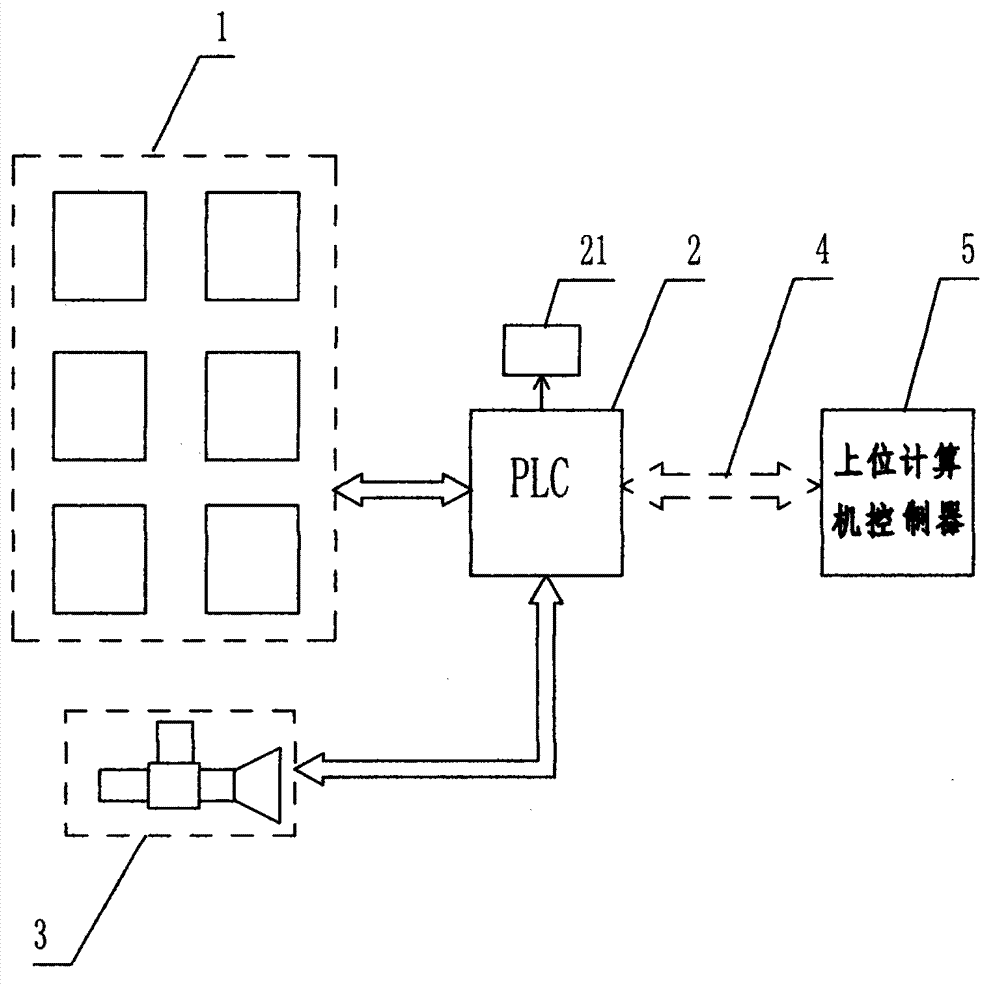

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. Embodiment: Referring to the figure, the safety control system for sludge thermal drying dry silo is characterized in that: an online instrument group 1 is provided, and the online instrument group includes: an online temperature sensor, an online pressure transmitter, an online oxygen content probe, An online carbon monoxide detection probe, a guided wave radar level gauge for measuring the height of the material level in the dry silo, and an online material level switch. There are 4 temperature sensors, which are evenly distributed on the side wall of the dry silo, and the height of each probe is 5 meters apart. The number of temperature sensors can be added or subtracted according to user needs and the size of the dry silo; there is a PLC control unit 2, which is equipped with an online The processing circuit module of the detection data of the instr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com