Horse bone protein powder rich in active calcium and preparation method thereof

A technology of active calcium and protein powder, used in food preparation, protein food processing, protein food ingredients and other directions, can solve the problems of calcium deficiency, unable to find calcium source, pollute the environment, etc., achieve good processing characteristics, promote human absorption, The effect of high water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment one: the preparation of rich active calcium horse bone protein powder

[0031] The preparation method of active calcium-rich horse bone protein powder, the specific preparation method steps are as follows:

[0032] (1) The fleshless raw horse bone is crushed to 10cm, soaked to remove blood, and dried at 50°C to obtain massive horse bone;

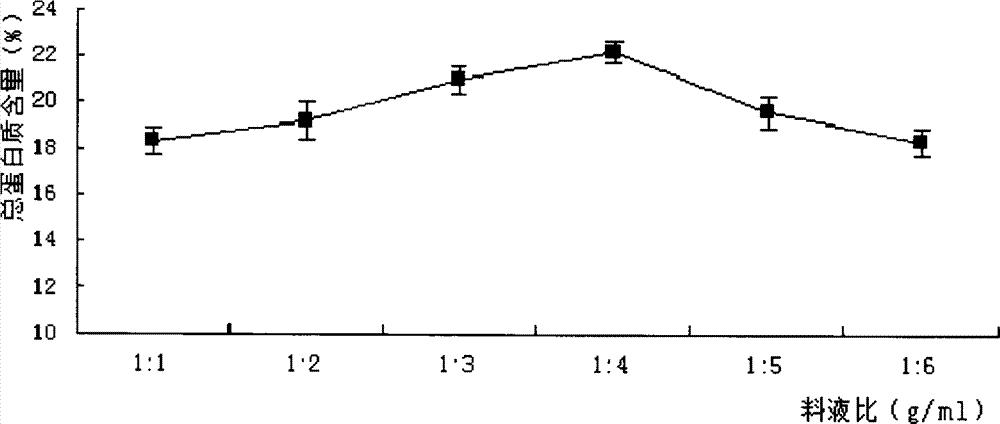

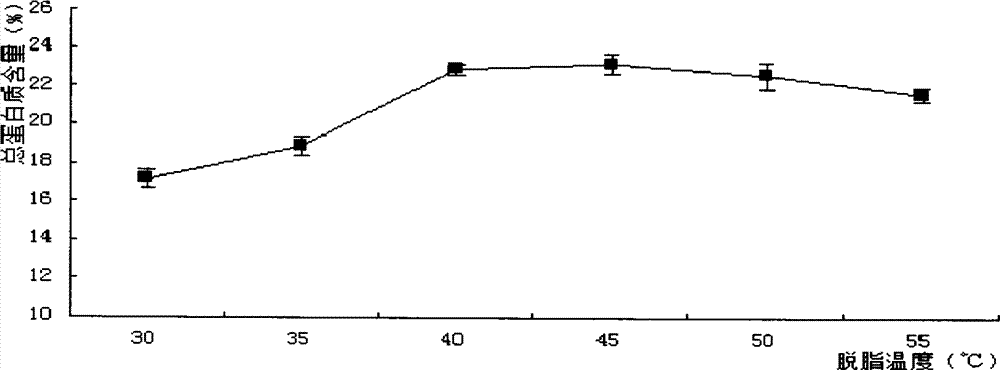

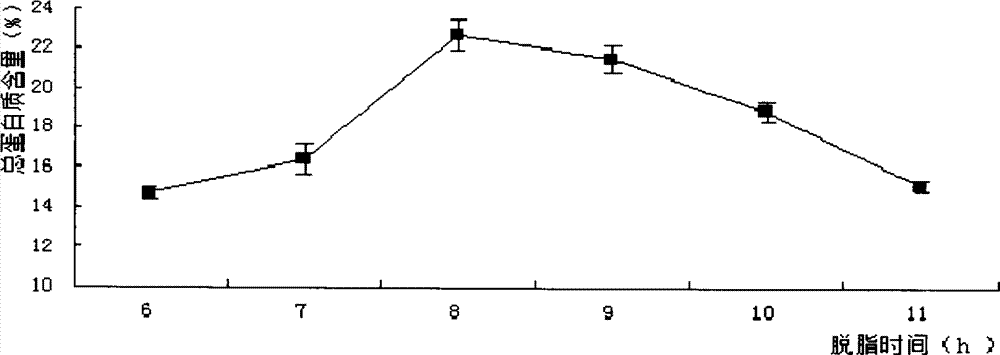

[0033] (2) Preparation of degreasing horse bone: using n-hexane as the degreasing reagent and total protein content as the index, select the solid-liquid ratio of massive horse bone and n-hexane as 1:5g / mL, degreasing temperature at 40°C, and degreasing time for 8h to obtain degreasing horse bone;

[0034] (3) Preparation of horse bone powder hydrolyzate: pulverize the defatted horse bone prepared in the above step (2), and sieve through 120 mesh to obtain bone powder; select alkaline protease, enzymolysis temperature is 45°C, and the concentration of bone powder aqueous solution is in m / m 8%, the enzymolysis pH value is ...

Embodiment 2

[0037] Embodiment two: the preparation of rich active calcium horse bone protein powder

[0038] The preparation method of active calcium-rich horse bone protein powder, the specific preparation method steps are as follows:

[0039] (1) The fleshless raw horse bone is broken to 10cm, soaked to remove blood, and dried at 55°C to obtain massive horse bone;

[0040] (2) Preparation of degreasing horse bone: using n-hexane as the degreasing reagent and total protein content as the index, select the solid-liquid ratio of massive horse bone and n-hexane as 1:4g / mL, degreasing temperature at 45°C, and degreasing time for 10h to obtain degreasing horse bone;

[0041] (3) Preparation of horse bone powder hydrolyzate: the degreased horse bone prepared in the above step (2) is pulverized and sieved with 120 mesh to obtain bone powder; alkaline protease is selected, the enzymolysis temperature is 55°C, and the concentration of the bone powder aqueous solution is m / m 10%, the enzymolysis...

Embodiment 3

[0043] Embodiment three: the preparation of active calcium horse bone protein powder

[0044] The preparation method of active calcium-rich horse bone protein powder, the specific preparation method steps are as follows:

[0045] (1) The fleshless raw horse bone is crushed to 10cm, soaked to remove blood, and dried at 50°C to obtain massive horse bone;

[0046] (2) Preparation of degreasing horse bone: using n-hexane as the degreasing reagent and total protein content as the index, select the solid-liquid ratio of massive horse bone and n-hexane as 1:3g / mL, degreasing temperature at 43°C, and degreasing time for 9h to obtain degreasing horse bone;

[0047] (3) Preparation of horse bone powder hydrolyzate: the degreased horse bone prepared in the above step (2) is pulverized and sieved with 120 mesh to obtain bone powder; alkaline protease is selected, the enzymolysis temperature is 50°C, and the concentration of the bone powder aqueous solution is m / m 9%, the enzymolysis pH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com