Antibacterial type inorganic whisker functional composite as well as preparation method and application thereof

A technology of functional composite materials and inorganic whiskers, applied in dental preparations, medical science, dentistry, etc., to achieve excellent antibacterial properties, improve the bonding force of organic-inorganic interfaces, and improve the effects of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

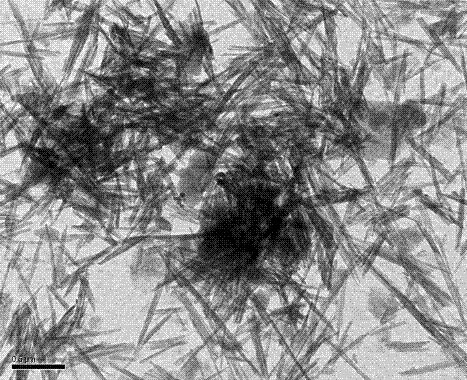

[0036] (1) Add 5 g of attapulgite whisker particles to 100 mL of deionized water and disperse them ultrasonically for 60 minutes to obtain a suspension of inorganic whisker particles; mix 0.5 g of cetyltrimethylammonium bromide and 0.5 g of γ-formazol Acryloyloxypropyltrimethoxysilane was dissolved in 20mL of absolute ethanol; the dispersed attapulgite whisker particle suspension was stirred, and the surfactant alcohol solution was added dropwise, the temperature was kept at 80°C, and the reaction 4 hours. Suction filtration, washing, drying and grinding to obtain modified inorganic whisker particles.

[0037] (2) Combine 5.0 g of the modified inorganic whisker particles obtained in step (1) and 400 mL of silver nitrate solution (0.03 mol / L) at 40°C for 8 hours under magnetic agitation, filter with suction, wash, dry, and grind to obtain antibacterial type inorganic whisker particles.

[0038] (3) Add 5.0g of antibacterial inorganic whisker particles prepared in step (2) int...

Embodiment 2

[0042] (1) Add 5 g of attapulgite whisker particles to 100 mL of deionized water, and disperse them ultrasonically for 60 minutes to obtain a suspension of inorganic whisker particles; add 0.3 g of cetyltrimethylammonium bromide, 0.2 g of Tetraalkyltrimethylammonium and 0.6g γ-methacryloxypropyltrimethoxysilane were dissolved in 20mL of absolute ethanol; the dispersed attapulgite whisker particle suspension was stirred and added dropwise Surfactant alcohol solution, the temperature was kept at 80°C, and reacted for 4 hours. Suction filtration, washing, drying and grinding to obtain modified inorganic whisker particles.

[0043] (2) Mix 5.0 g of the modified inorganic whisker particles obtained in step (1) with 400 mL of [Ag(NH 3 ) 2 ] Cl solution (0.01mol / L) was stirred at 50° C. for 7 hours by magnetic force to prepare the antibacterial agent. Suction filtration, washing, drying and grinding to obtain the inorganic whisker antibacterial agent.

[0044] (3) Add 5.0g of the...

Embodiment 3

[0048] (1) Add 5 g of attapulgite whisker particles to 100 mL of deionized water and disperse them ultrasonically for 30 minutes to obtain a suspension of inorganic whisker particles; mix 0.5 g of tetradecyltrimethylammonium chloride and 0.8 g of γ-formazol Acryloyloxypropyltrimethoxysilane was dissolved in 20mL of absolute ethanol; the dispersed attapulgite whisker particle suspension was stirred, and the surfactant alcohol solution was added dropwise, and the temperature was kept at 80°C. React for 4 hours. Suction filtration, washing, drying and grinding to obtain modified inorganic whisker particles.

[0049] (2) 5.0 g of the modified inorganic whisker particles obtained in step (1) and 300 mL of copper nitrate solution (0.01 mol / L) were magnetically stirred at 50° C. for 9 hours to prepare an antibacterial agent. Suction filtration, washing, drying and grinding to obtain the inorganic whisker antibacterial agent.

[0050] (3) Add 5.0g of antibacterial inorganic whisker ...

PUM

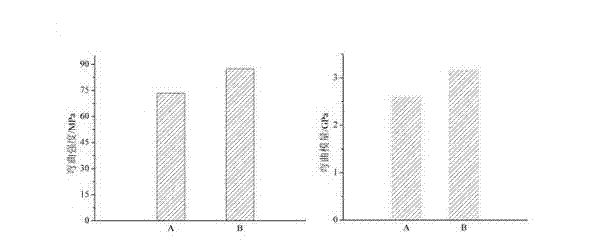

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com