Preparation method of precious metal nano-particles

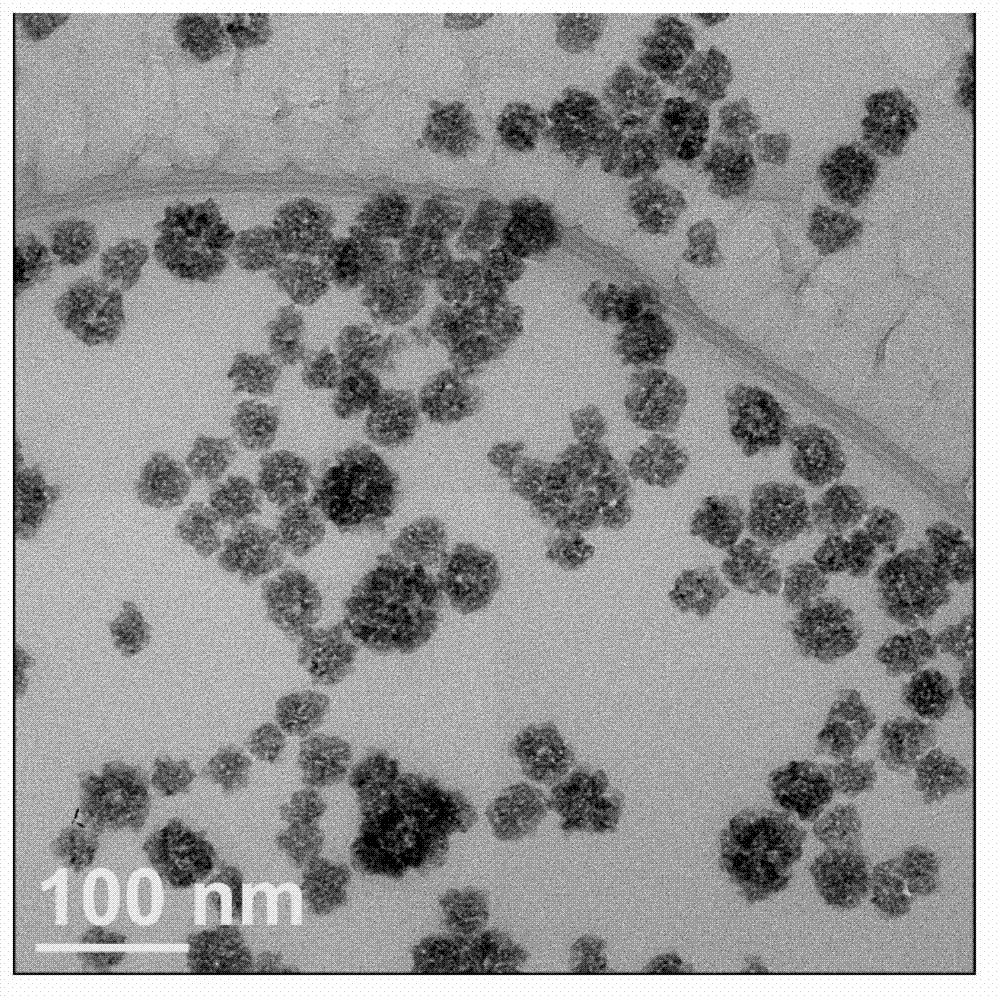

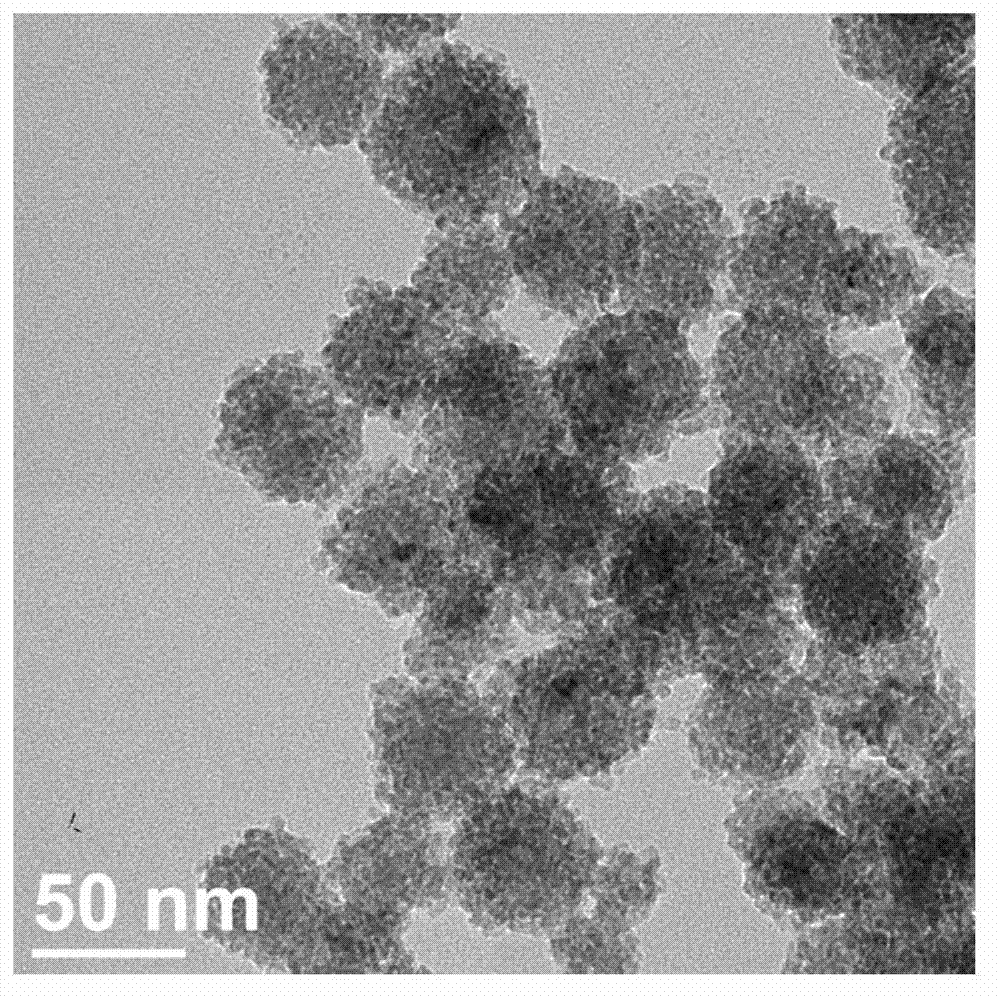

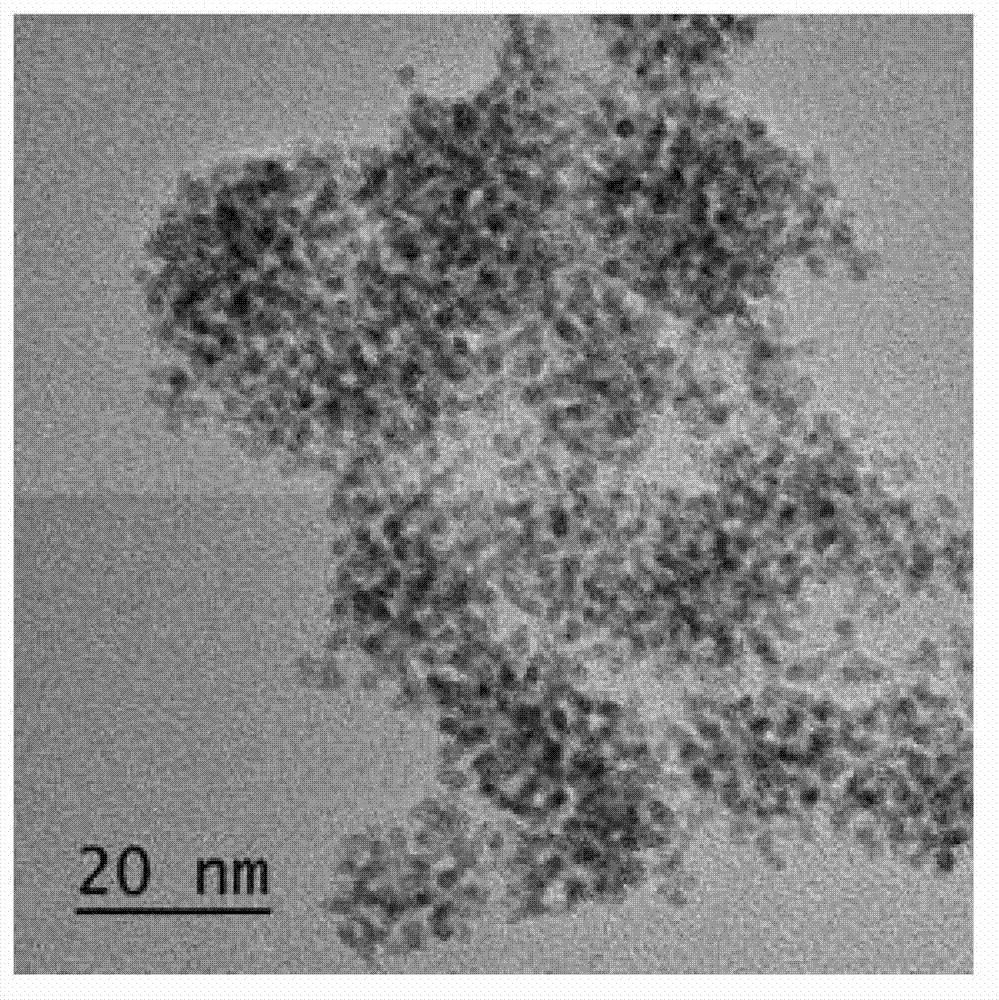

A nanoparticle and precious metal technology, applied in the field of nanoparticle preparation, can solve the problems of uncontrollable nanoparticle size and affect the functionality of nanoparticles, and achieve good surface-enhanced Raman effect, high current density, and uniform particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0035] Specific embodiment 1: In this embodiment, a method for preparing noble metal nanoparticles is specifically prepared according to the following steps:

[0036] 1. Preparation of cuprous oxide nanoparticles: Add surfactant and copper salt solution into ultrapure water, stir evenly, then add sodium hydroxide solution, keep for 10min~12min, then add ascorbic acid solution, keep for 30min~40min, get product solution, and then centrifuge the product solution at a speed of 8000rpm~15000rpm for 5min~10min, and then wash the obtained solid phase with deionized water for 3~5 times to obtain cuprous oxide nanoparticles; wherein, the copper salt solution The concentration of sodium hydroxide solution is 0.01mol / L~1mol / L, the concentration of sodium hydroxide solution is 0.1mol / L~6.1mol / L, the concentration of ascorbic acid solution is 0.1mol / L~2mol / L; the quality of surfactant and copper The ratio of the amount of salt is (3g~3.33g): 0.1mmol, the ratio of the mass of surfactant to...

specific Embodiment approach 2

[0039] Embodiment 2: This embodiment is different from Embodiment 1 in that the surfactant in step 1 is polyvinyl alcohol or polyvinylpyrrolidone. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0040] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the copper salt solution in step 1 is copper acetate solution, copper chloride solution, copper nitrate solution or copper sulfate solution. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com