Method and device for removing heavy metals in industrial sewage by electromagnetic stirring paddle

An industrial wastewater, electromagnetic stirring technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. nZVI recycling and other issues, to achieve the effect of low cost, low energy consumption and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

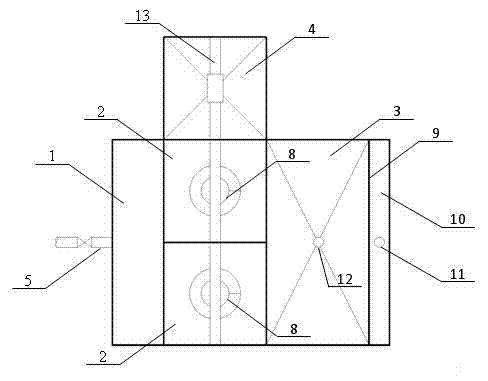

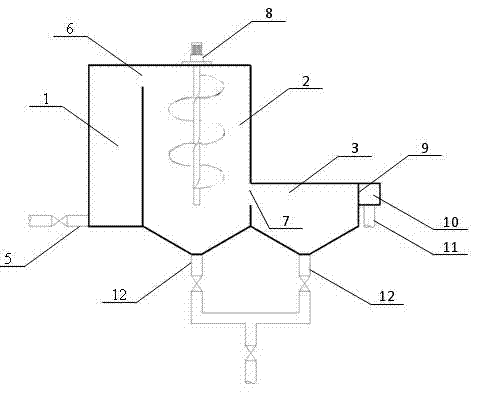

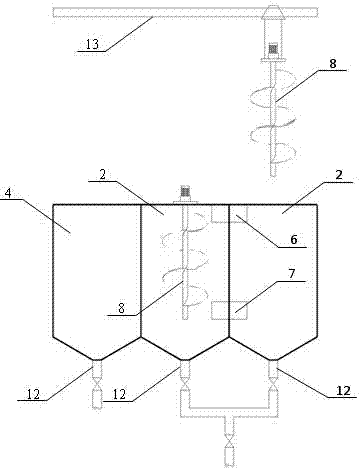

[0036] Such as Figure 1-Figure 7 As shown, the device includes a diversion area 1, a reaction area 2, a precipitation area 3 and a recovery area 4, industrial waste water enters the diversion area 1 through a water inlet pipe 5, and the diversion area 1 communicates with the reaction area 2 through a diversion port 6 , the reaction zone 2 communicates with the precipitation zone 3 through the water outlet 7 . The removal process of heavy metals and the solid-liquid separation process of nZVI mainly take place in the reaction zone 2, wherein: the electromagnetic stirring paddle 8 is the main component of the reaction zone 2, and the effluent of the precipitation zone 3 flows into the overflow type sump 10 through the zigzag weir 9 Finally, the device is discharged through the water outlet pipe 11. When the device needs to be drained for maintenance or nZVI is recovered, the water or nZVI is discharged from the device through the drain port 12, and the electromagnetic stirring ...

Embodiment 2

[0039] The electroplating wastewater stock solution at the outlet of the electroplating workshop of an electroplating factory is taken, and the electroplating wastewater stock solution is firstly pretreated by adding flocculant, so that the suspended impurities in the electroplating wastewater stock solution are removed with the formation of flocculant precipitation, thereby obtaining clarified electroplating wastewater. Pretreated electroplating wastewater containing Cu 2+ 300-800 mg / L, pH value between 7-8.5. In this study, a certain amount of nZVI is added to the pretreated electroplating wastewater in batches. After the pretreated clarified electroplating wastewater enters the reaction area through the diversion port in the diversion area, the diversion port and the water outlet pass through the baffle at the same time. The area is sealed, and under the rapid stirring of the stirring paddle, it can fully contact and react with nZVI for 0.5-2.0 h, so as to realize the remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com