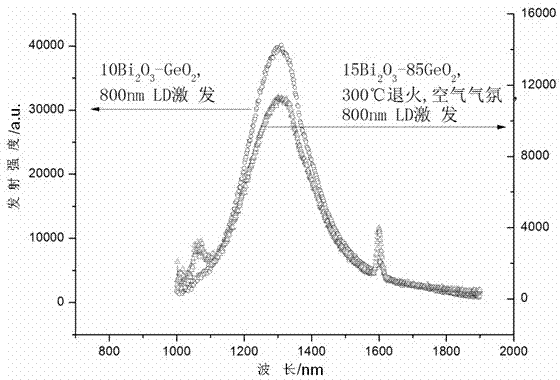

Bi2O3/GeO2 glass with ultra-wideband near infrared luminescence function and fabrication method

A near-infrared and ultra-broadband technology, applied in the field of broadband near-infrared luminescent glass, can solve the problem of low Bi ion doping concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

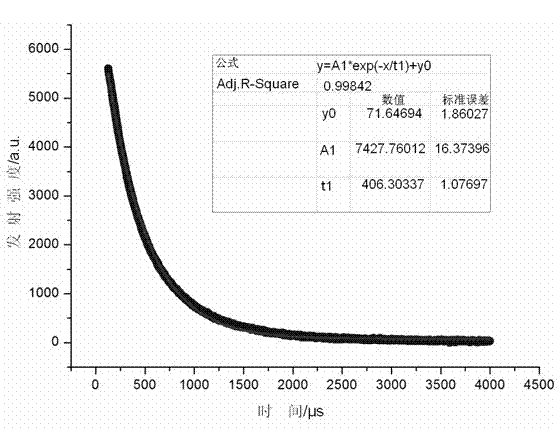

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Preparation of 10Bi by Melting and Quenching 2 o 3 / 90GeO 2 Glass

[0025] Step 1, using Bi 2 o 3 and GeO 2 As a raw material, according to the molar ratio Bi 2 o 3 : GeO 2 =1 : 9 Make the ingredients, mix them evenly and press them into blocks, then put them into a platinum crucible with a platinum sheet as a cover.

[0026] Step 2: Put the platinum crucible filled with raw materials into the furnace. The heating element of the muffle furnace is a silicon carbide rod. The heating rate is 120°C / h, the temperature of the chemical material is 1150°C, and the holding time is 30 minutes.

[0027] Step 3: Pour the melted raw material in the crucible into a preheated metal copper mold, and cool it to room temperature by air to prepare a glass sample.

[0028] In step 4, the prepared glass sample is annealed, the annealing temperature is 500° C., the annealing time is 10 h, and the annealing atmosphere is air.

Embodiment 2

[0029] Example 2: Preparation of 15Bi by Melting and Quenching 2 o 3 / 85GeO 2 Glass

[0030] Step 1, using Bi 2 o 3 and GeO 2 As a raw material, according to the molar ratio Bi 2 o 3 : GeO 2 =1.5 : 8.5 Prepare the ingredients, mix them evenly and press them into blocks, then put them into a platinum crucible with a platinum sheet as a cover.

[0031] Step 2: Put the platinum crucible filled with raw materials into the furnace. The heating element of the muffle furnace is a silicon carbide rod. The heating rate is 150°C / h, the temperature of the chemical material is 1100°C, and the holding time is 25 minutes.

[0032] Step 3: Pour the melted raw material in the crucible into a preheated metal copper mold, and air cool to room temperature to prepare a glass sample.

Embodiment 3

[0033] Example 3: Preparation of 20Bi by Melting and Quenching 2 o 3 / 80GeO 2 Glass

[0034] Step 1, using Bi 2 o 3 and GeO 2 As a raw material, according to the molar ratio Bi 2 o 3 : GeO2=2 : 8 Make the ingredients, mix them evenly and press them into blocks, then put them into an alumina crucible with an alumina sheet as a cover.

[0035] Step 2: Put the alumina crucible filled with raw materials into the furnace. The heating element of the muffle furnace is a silicon carbide rod. The heating rate is 100°C / h, the temperature of the chemical material is 1100°C, and the holding time is 30 minutes.

[0036]Step 3: Pour the melted raw materials in the crucible into a preheated platinum mold, and air cool to room temperature to prepare a glass sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com