Ytterbium-doped fluorphosphate glass with large emission section and preparation method of ytterbium-doped fluorphosphate glass

A technology of ytterbium fluorophosphate and glass, which is applied in the field of large emission cross-section ytterbium-doped fluorophosphate glass and its preparation, to achieve the effects of improving low-temperature viscosity, large gain coefficient, and high stimulated emission cross-section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

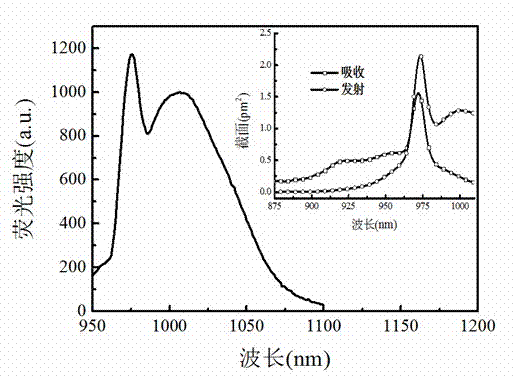

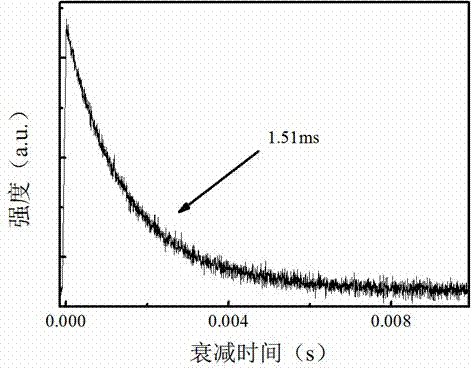

Image

Examples

Embodiment 1

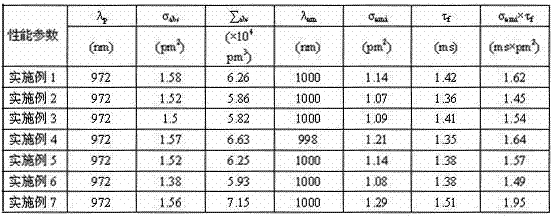

[0031] Embodiment 1~7 component designs are as table 1 (unit is mol%, Yb 2 o 3 Doping amount is 1wt%):

[0032] Table 1 Distribution ratio of glass components

[0033] Element Example 1 Example 2 Example 3 Example 4 Example 5 Example 6 Example 7 BaO 6 6 6 6 6 6 6 al 2 o 3 2 2 2 2 2 2 2 P 2 o 5 20 15 15 15 12.5 10 15 ZrF 4 17 17 17 17 17 17 17 CaF 2 9.5 9.5 9.5 9.5 9.5 9.5 0 SrF 2 12.5 12.5 12.5 12.5 12.5 12.5 18.5 BaF 2 14.5 14.5 14.5 14.5 14.5 14.5 16 PbF 2 18.5 18.5 18.5 18.5 18.5 18.5 20.5 Nb 2 o 5 5 Bi 2 o 3 5 TeO 2 5 7.5 10 5

[0034] Embodiment 1~7 adopts identical preparation method, and step is as follows:

[0035] First, weigh the raw material according to the formula, mix it well and add it into the graphite crucible; then, put the graphite crucible in the quar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com