Extractive distillation method of butadiene

A technology of extractive distillation and butadiene, applied in the direction of distillation purification/separation, organic chemistry, etc., to achieve the effects of reducing the amount of extractant, saving energy consumption, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

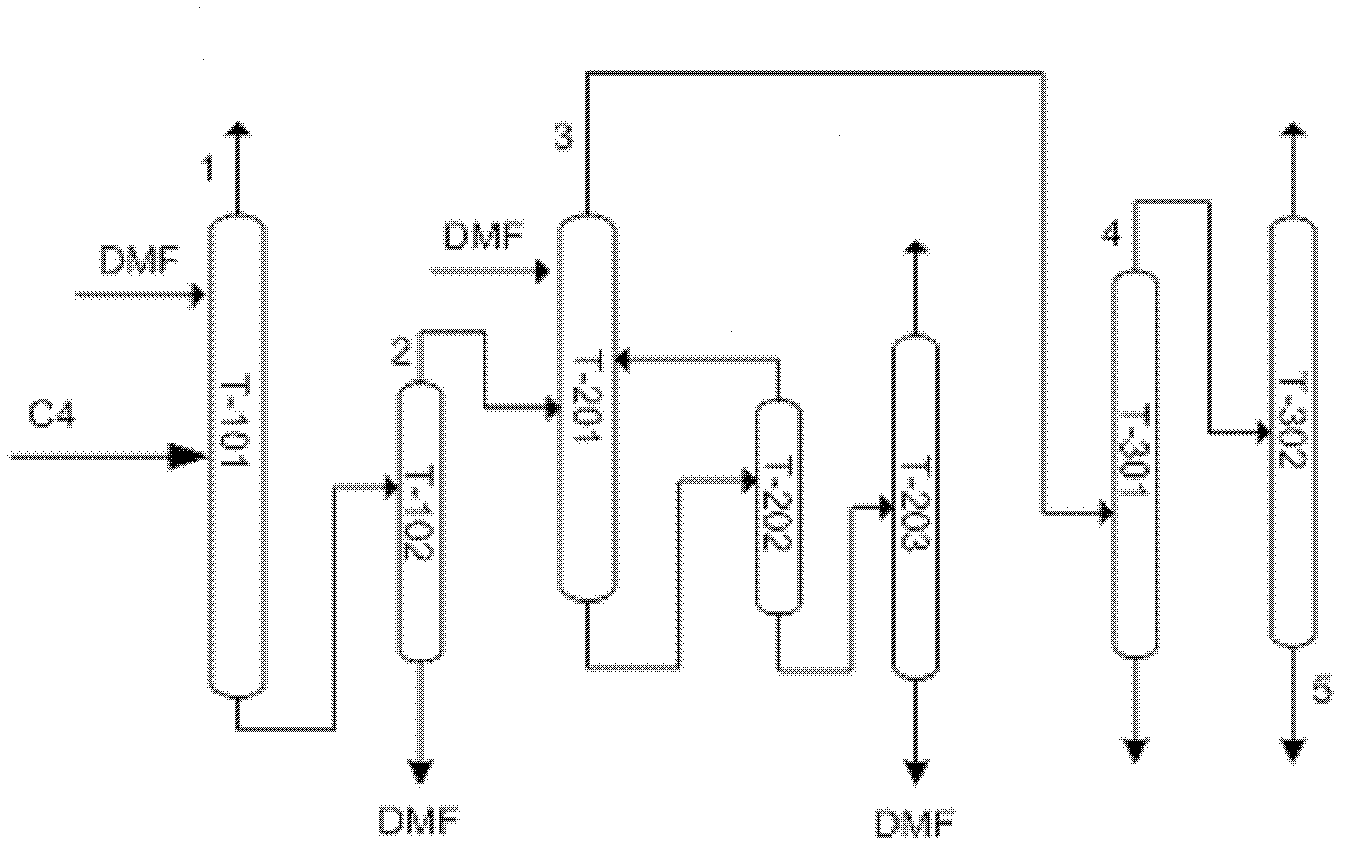

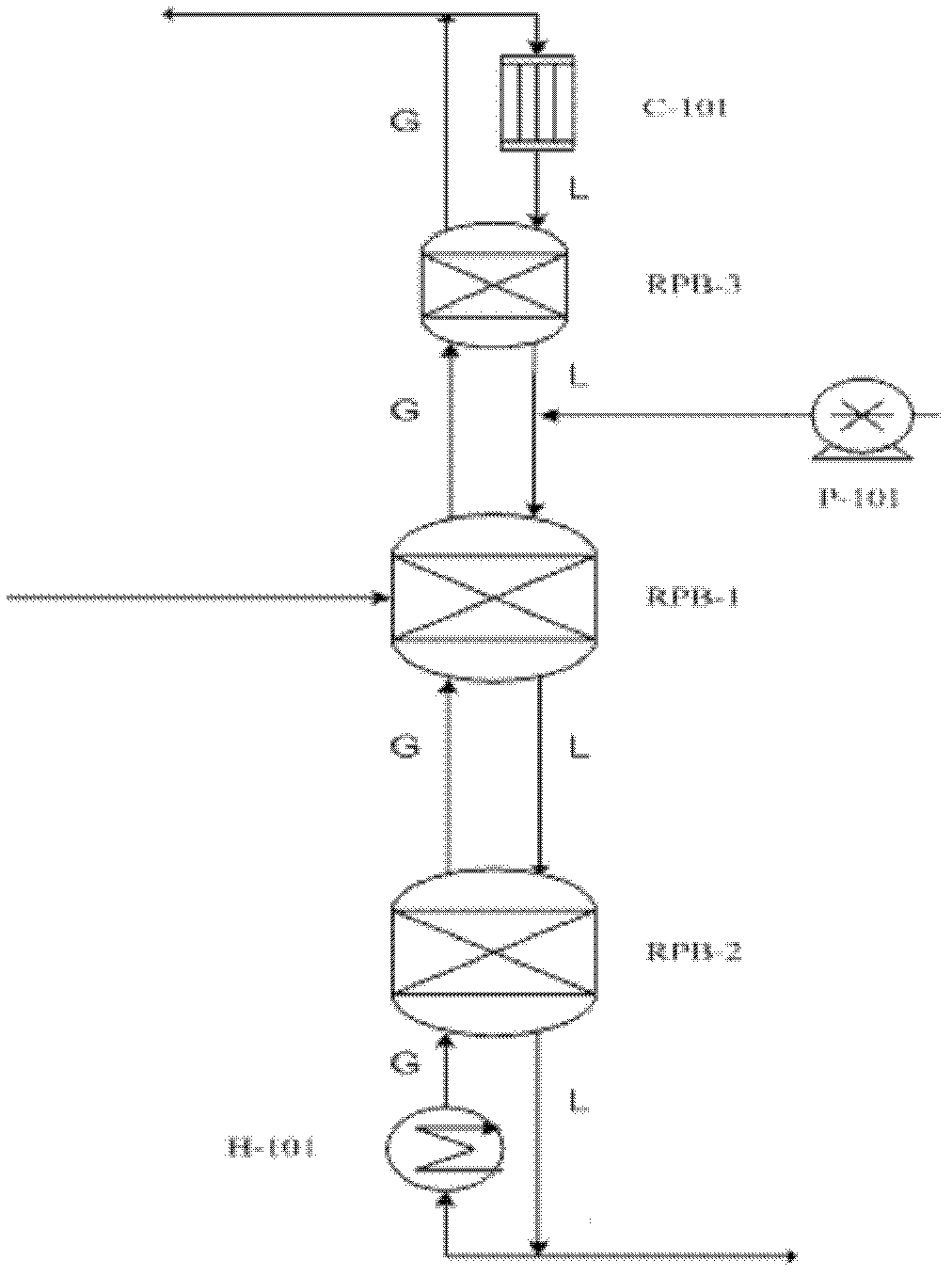

[0044] With DMF extractant,

[0045] Gas-phase carbon four raw materials (mainly composed of n-butane 4.89%, isobutane 2.76%, n-butene 13.42%, isobutene 13.65%, trans-2-butene 5.76%, cis-2-butene 6.04%, 1,3 -butadiene 48.02%, 1,2-butadiene 2.38%, methyl acetylene 0.21%, ethyl acetylene 1.13%, vinyl acetylene 1.59%, carbon five and above heavy components 0.06%) first enter the supergravity extraction The first stage of the distillation unit, the butane and butene components are removed from the gas outlet of the high-gravity rectification section, and the solvent-rich liquid containing butadiene after extractive distillation is extracted from the extractive distillation unit and enters the first stripping unit T- 102 resolves the C4 fraction.

[0046] The reflux ratio of controlling extractive distillation is 1.1, and solvent ratio is 7: 1, and (one section of supergravity extractive distillation device) plate number is 220, and operating pressure is 0.38MPa, and the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com