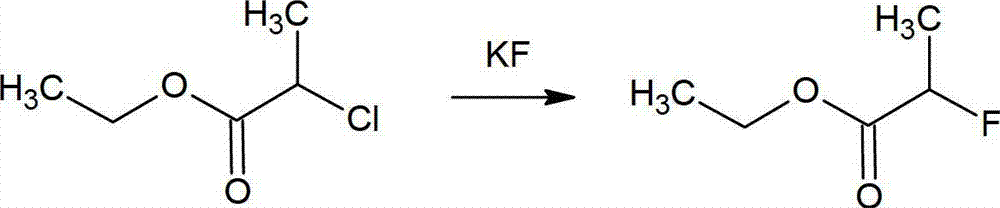

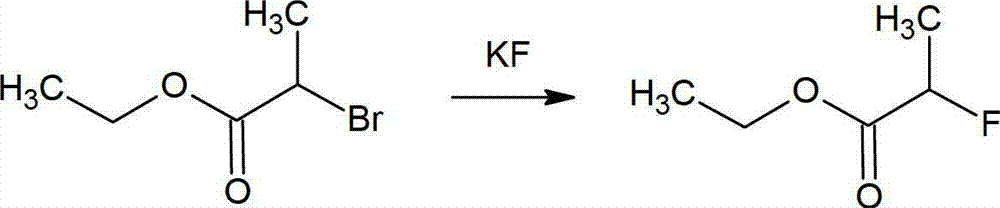

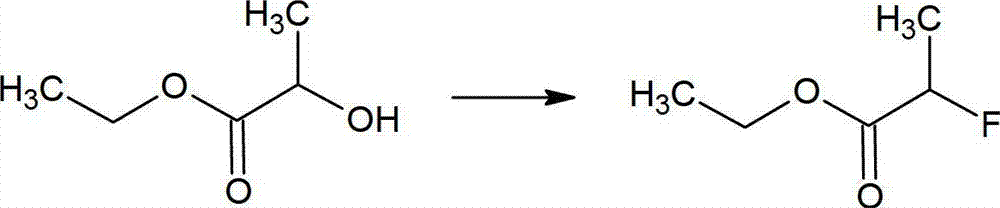

Method for preparing 2-fluoropropionate

A technology of fluoropropionate and chloropropionate, which is applied in the field of preparation of 2-fluoropropionate, can solve the problems of unavailable reaction raw materials and high production cost, and achieve low production of three wastes, low production cost and high product selection sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In a stainless steel reaction kettle, add 100g ethyl 2-chloropropionate, 120g hydrogen fluoride and 2.0g titanium tetrachloride, stir and react at a temperature of 60°C for 24h, then pour the reaction solution into ice water, fully stir and mix, and use The crude product of ethyl 2-fluoropropionate was separated by separating funnel, and the crude product was rectified under reduced pressure to obtain 68.5g of ethyl 2-fluoropropionate product, the reaction yield was 77.7%, the product selectivity was 87.0%, and the content determined by GC was 98.2 %.

Embodiment 2

[0029] In a stainless steel reaction kettle, add 100g of ethyl 2-chloropropionate, 120g of hydrogen fluoride and 1.0g of tin tetrachloride, and after stirring for a reaction time of 30h at a temperature of 180°C, the reaction solution is poured into ice water, fully stirred and mixed, Separate the crude product of ethyl 2-fluoropropionate with a separating funnel, and rectify the crude product under reduced pressure to obtain 70.5g of ethyl 2-fluoropropionate product, the reaction yield is 80.0%, the product selectivity is 84.2%, and the content measured by GC is 98.5%.

Embodiment 3

[0031] In a stainless steel reaction kettle, add 100g methyl 2-chloropropionate, 130g hydrogen fluoride and 2.0g tin tetrachloride, stir and react at 80°C for 26h, then pour the reaction solution into ice water, fully stir and mix, divide The liquid funnel separated the oil phase to obtain the crude product of methyl 2-fluoropropionate. The crude product was rectified under reduced pressure to obtain 71.9 g of methyl 2-fluoropropionate. The reaction yield was 83.2%, and the product selectivity was 87.5%. The content was determined by GC 98.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com