Capric acid gel solid-solid phase change material and method thereof

A technology of solid-solid phase change material and capric acid, which is applied in the field of capric acid gel solid-solid phase change material, can solve problems such as leakage, and achieve the effect of simple process flow and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Process and steps in the present embodiment are as follows:

[0018] Weigh a certain amount of capric acid and put it into a container, heat the container in a 70°C water bath to dissolve all the capric acid; add the radiation sensitizer trimethylolpropane trimethacrylate (TMPTMA) In the dissolved capric acid solution, the content of trimethylolpropane trimethacrylate is 5% of the capric acid amount. Put the container into an ultrasonic cleaner with a water temperature of 70°C-80°C, and oscillate ultrasonically for 15 minutes, so that the two liquids of capric acid and trimethylolpropane trimethacrylate are fully miscible to obtain trimethylolpropane The decanoic acid solution of trimethacrylate; continue to keep the trimethylolpropane trimethacrylate decanoic acid system in a liquid state (at a temperature of 70°C), flush nitrogen into the liquid in the container for 15 minutes, and remove the oxygen in the container Drain, seal container. Under roo...

Embodiment 2

[0022] Change following conditions, other conditions are with embodiment 1.

[0023] Add the radiation sensitizer triethylene glycol dimethacrylate (TMPTMA) into the dissolved capric acid solution, wherein the content of triethylene glycol dimethacrylate is 1% of the amount of capric acid %—9%, the irradiation dose is 120kGy.

[0024] Put the irradiated samples into an oven at 70°C for 1 hour to keep warm. Observe the samples. It is found that except for the samples without radiation sensitizer which are transparent liquids, other irradiated samples have white solids. Taking the capric acid system with 3% radiation sensitizer as an example, the irradiation dose was 120 kGy. The irradiated sample was extracted by Soxhlet extractor, and the gel content of the sample was calculated to be 7.9%.

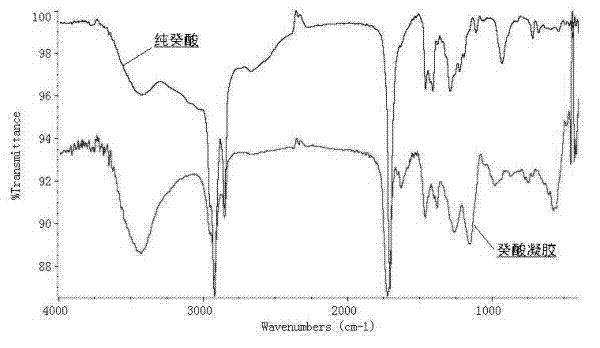

[0025] The invention adopts the electron beam irradiation technology, and by adding a radiation sensitizer, the decanoic acid molecule containing long-chain hydrocarbons undergoes hydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com