Natural bamboo fiber shirt fabric and manufacture method thereof

A technology of tencel fiber and tencel bamboo is applied in the field of shirt fabrics, which can solve the problems of easy deformation and light resistance of fabrics, rough and hard texture of fabrics, etc., and achieve the effects of good drape, preventing mutual staining and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

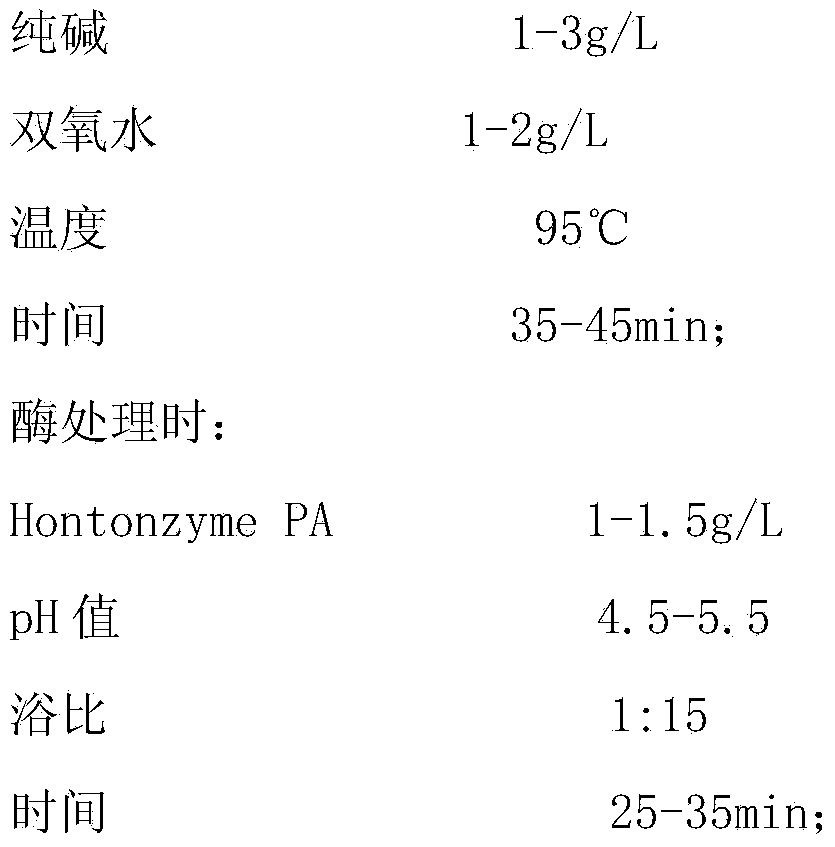

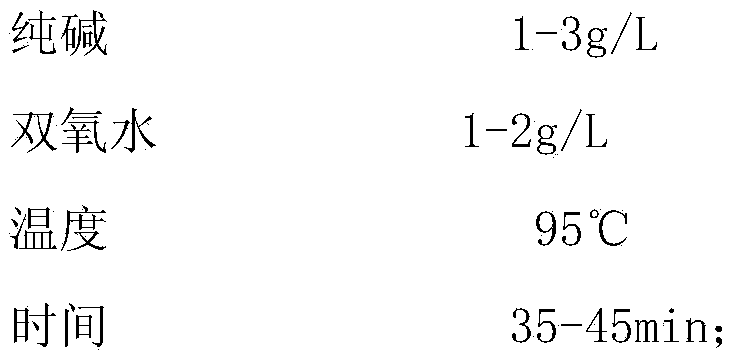

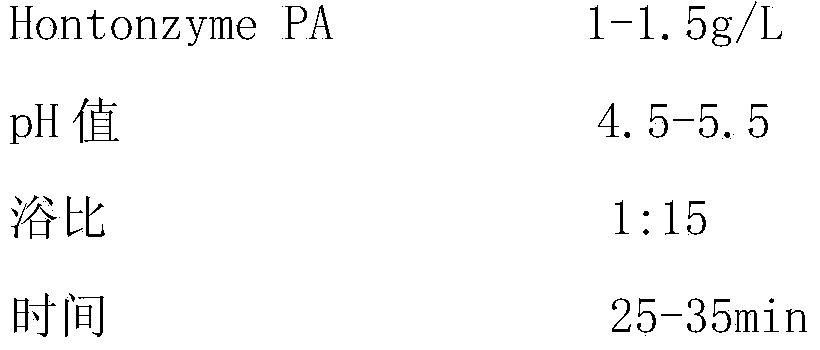

Method used

Image

Examples

Embodiment Construction

[0042] 1. Prepare Tencel / Bamboo Viscose Blended Shirt Fabric. The Tencel Bamboo Viscose Blended Shirt Fabric is made of Tencel and Bamboo Viscose Fiber. Glue fiber 5014.8tex.

[0043] Finished product: 147cm CF Tencel 50 / Bamboo Viscose 5014.8tex×CF Tencel 50 / Bamboo Viscose 5014.8tex512 / 10cm×338.5 / 10cm Tencel Bamboo Viscose Blended Shirt Fabric

[0044] Gray fabric: 160cm CF Tencel 50 / Bamboo Viscose Fiber 5014.8tex×CF Tencel 50 / Bamboo Viscose Fiber 5014.8tex472 / 10cm×338.5 / 10cm Tencel Bamboo Viscose Blended Shirt Fabric

[0045] Fabric weave: 3 / 1+1 / 1

[0046] 2. Technological process

[0047] 1. Spinning process

[0048] Warp and weft: CF Tencel 50 / Bamboo Viscose 50, 14.8tex (40s)

[0049] A002D disc bale machine→A035E mixed cotton opener→FA106 cotton opener→A092A oscillating cotton feeder→A076E lapping machine→A186F carding machine→FA306A drawing frame (head paralleling)→FA306A drawing frame (two paralleling) )→FA306A (finishing)→JWF1415 roving frame→DTM129 spinning frame→...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com