Method for preparing anti-adhesive membrane for surgeries

An anti-adhesion film, surgical technology, applied in the direction of surgery, medical science, etc., to achieve the effect of stable structure, wide application range and no immunogenicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

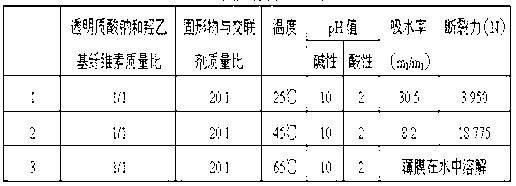

Embodiment 1

[0028] (1) Dissolve sodium hyaluronate with a molecular weight of 3000 kD and hydroxyethyl cellulose with a molecular weight of 90 kD in deionized water to prepare a solution with a concentration of 1.0% of sodium hyaluronate and hydroxyethyl cellulose, and use hydrogen The sodium oxide solution adjusts the pH value to 10 to obtain an alkaline solution;

[0029] (2) Add 1,4-butanediol diglycidyl ether to the alkaline solution, the mass ratio of it to solid matter is 1:20, stir evenly, and react at 25°C, 45°C, and 65°C respectively. The time is 2 hours;

[0030] (3) Add acetic acid to adjust the pH value of the solution to 2, stir well and evenly degas, pour it into a mold for casting, react at 25°C, 45°C, and 65°C respectively, and dry to form a film.

[0031] (4) The membrane was purified in deionized water for 8 h, and dried to constant weight at 37°C to obtain a double cross-linked sodium hyaluronate membrane.

[0032] The double-crosslinked film obtained by reacting at 2...

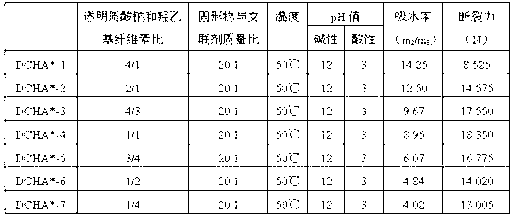

Embodiment 2

[0037] (1) Sodium hyaluronate with a molecular weight of 1700 kD and hydroxyethyl cellulose with a molecular weight of 200 kD were dissolved in deionized water to prepare a solution with a mass concentration of 1.0% of sodium hyaluronate and hydroxyethyl cellulose. Sodium hydroxide solution adjusts the pH value to 11 to obtain an alkaline solution;

[0038] (2) Add 1,4-butanediol diglycidyl ether to the alkaline solution, see Table 2 for the amount added, stir evenly, and react at 45°C for 2 hours;

[0039] (3) Add acetic acid to adjust the pH value of the solution to 4, stir well and evenly degas, pour it into a mold for casting, react at 45°C, and dry to form a film.

[0040](4) The membrane was purified in deionized water for 8 h, and dried to constant weight at 37°C to obtain a double cross-linked sodium hyaluronate membrane.

[0041] When the mass ratio of solids to crosslinking agent is 20:1, the obtained film has the best physical properties, with suitable water absorp...

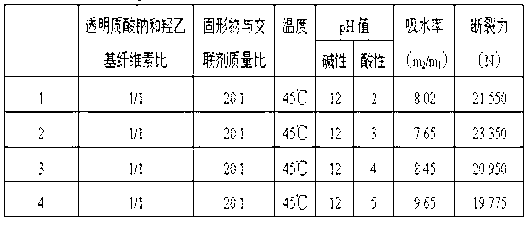

Embodiment 3

[0046] (1) Sodium hyaluronate with a molecular weight of 1500 kD and hydroxyethyl cellulose with a molecular weight of 90 kD were dissolved in deionized water to prepare sodium hyaluronate with a mass concentration of 1.0% and hydroxyethyl cellulose with a mass concentration of 0.25% ~4.0% solution, use sodium hydroxide solution to adjust the pH value to 12 to obtain an alkaline solution;

[0047] (2) Add epoxy compound cross-linking agent 1,4-butanediol diglycidyl ether to the alkaline solution, the mass ratio of it to solid matter is 1:20, stir evenly, react at 45°C, and the reaction time is 2 hours;

[0048] (3) Add acetic acid to adjust the pH value of the solution to 3, stir well and evenly degas, pour it into a mold for casting, react at 45°C, and dry until a film is formed.

[0049] (4) The membrane was purified in deionized water for 10 h, and dried to constant weight at room temperature to obtain a double cross-linked sodium hyaluronate membrane.

[0050] With the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com