A method and device for enriching and enriching stable isotopes 2h, 18o, 13c

A stable isotope and isotope technology, which is applied in the separation of different isotopic elements, separation methods, chemical instruments and methods, etc., can solve the problems of long system balance time, large investment, and difficult amplification, etc., and achieve system balance time. The effect of small liquid volume and easy operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

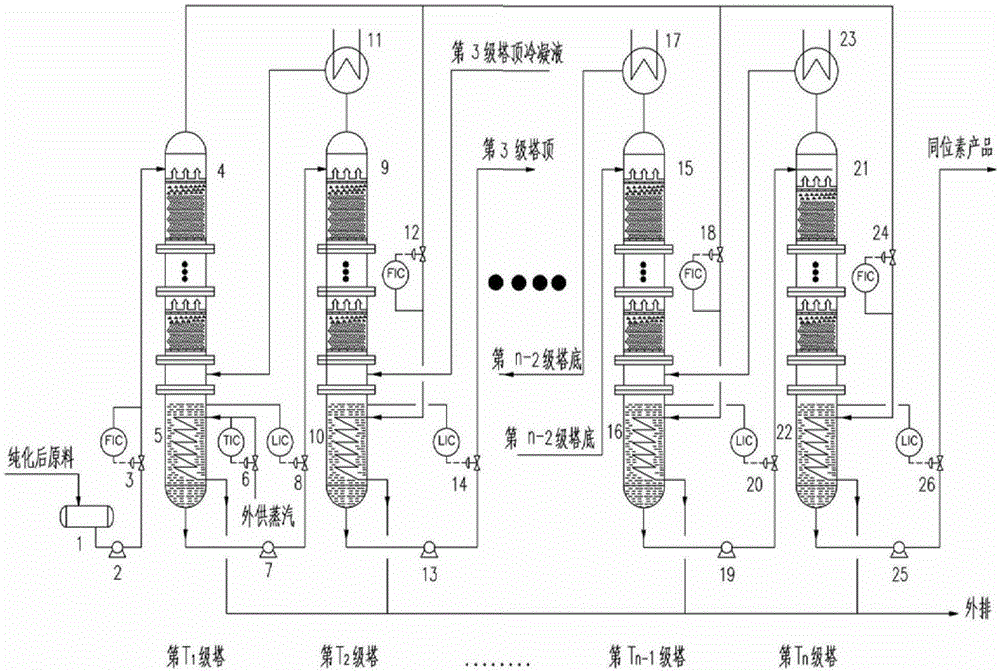

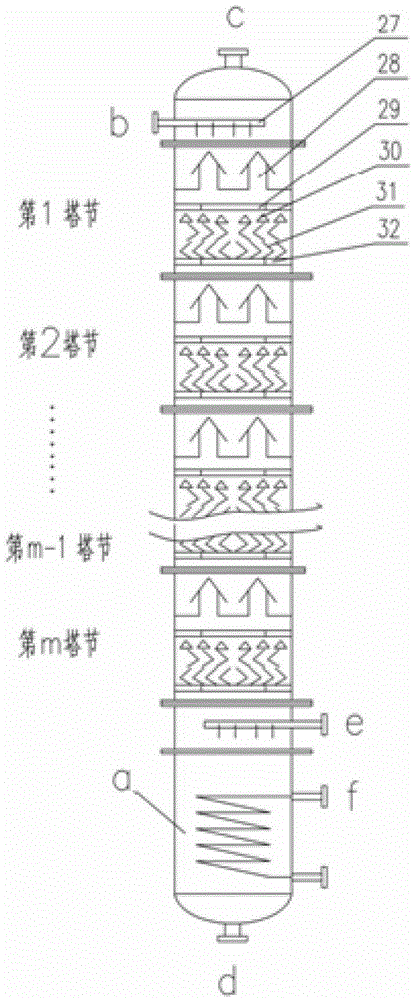

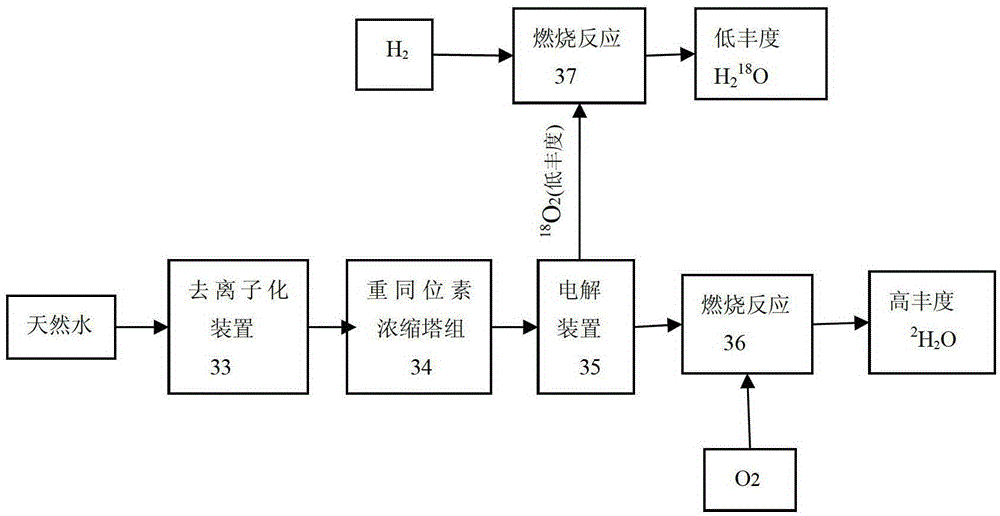

[0031] Such as image 3 As shown, the natural water is purified through the deionization device 33 and enters the heavy isotope enrichment tower group 34. The heavy isotope enrichment tower group is composed of two stages of vapor-liquid mass transfer towers connected in series, and each vapor-liquid mass transfer tower consists of 6 sections Tower section composition (ie n=2, m=6). heavy isotope 2 After H(D) is concentrated to 99%, it enters the electrolysis device 35, and the high-abundance 99% 2 h 2 The gas is input O with the outside world in the combustion reaction device 36 2 Combined, eventually cooled to a normalized 99% high abundance 2 h 2 O; low abundance from the electrolysis unit 18 o 2 In the combustion reaction device 37, with the external high-purity H 2 Combined, after cooling, the low-abundance by-product H is finally formed 2 18 O products.

Embodiment 2

[0033] Such as Figure 4 As shown, the natural water is purified through the deionization device 38 and enters the heavy isotope enrichment tower group 39. The heavy isotope enrichment tower group is composed of 4 stages of vapor-liquid mass transfer towers connected in series, and each stage of vapor-liquid mass transfer towers consists of 6 sections Tower section composition (ie n=4, m=6). heavy isotope 18 After O is concentrated to 98%, it enters the electrolysis device 40, and the high-abundance (98%) 18 o 2 The gas enters H in the combustion reaction device 42 and the outside world 2 combined, and finally cooled to a normalized 98% high-abundance H 2 18 O; low abundance from the electrolysis unit 2 h 2 (also known as D 2 ) in the combustion reaction device 41, with the external high-purity O 2 Combined, cooled to form low-abundance by-products 2 h 2 O (also known as D 2 o) Products.

Embodiment 3

[0035] Such as Figure 5 shown, taking natural methane CH 4 The raw material is dried and purified in the drying and dehydrating device 43, and then enters the heavy isotope enrichment tower group 44. The heavy isotope enrichment tower group is composed of 6 stages of vapor-liquid mass transfer towers connected in series, and each stage of vapor-liquid mass transfer tower consists of 6 Section tower section composition (ie n=6, m=6). heavy isotope 13 After C is concentrated to an abundance of more than 99%, it enters the combustion reaction device 45 and combines with high-purity O2 from the outside. After cooling, the gas phase part is a product with a high abundance of 99%. 13 CO 2 , the liquid phase is a by-product of low abundance 2 h 2 O (also known as D 2 o) Products.

[0036] The following table is three implementation cases of the present invention, but the scope of the present invention is not limited to embodiment:

[0037]

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com