Cross-linking type polybenzimidazole porous separation membrane and preparation method and application thereof

A polybenzimidazole, porous separation membrane technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology and other directions, to achieve good application prospects and markets, excellent solvent resistance, excellent chemical stability and mechanical stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The preparation method of the cross-linked polybenzimidazole porous separation membrane of the present invention, the steps are as follows:

[0060] (1) Dissolve polybenzimidazole in one or more mixed solvents of DMSO, DMF and DMAC with THF or n-hexane to form a polymer solution with a concentration of 5-40 wt%; the solvents in the mixed solvent are in any proportion or equal proportions;

[0061] (2) Coat the polymer solution on a glass plate or non-woven fabric, volatilize the coated solution in the air for 0-20 minutes, and then immerse in water for 1-60 minutes to form a polybenzimidazole porous separation membrane with a thickness of 20 -1000um;

[0062] (3) Soak the polybenzimidazole porous separation membrane in a solution containing a cross-linking agent at 25-100 o Under the condition of C, soak for 0.5-200 hours to obtain a cross-linked polybenzimidazole porous separation membrane.

[0063] Wherein the cross-linking agent in the solution containing the cro...

Embodiment 1

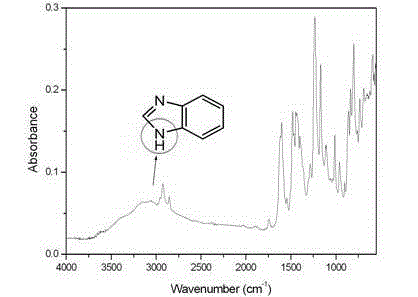

[0068] 10 g of polybenzimidazole (weight average molecular weight about 50,000) having the following structure was dissolved in 50 ml of N, N-dimethylacetamide to prepare a 20% polymer solution. The solution was cast onto a glass plate and flattened with a casting knife. Then quickly immersed in 5L of water, solidified for 5 minutes to form a porous separation membrane to obtain a porous membrane of polybenzimidazole. The porous separation membrane of polybenzimidazole was cross-linked in 5% methanol solution of p-dichlorobenzylbenzene for 24 hours to obtain a solvent-resistant nanofiltration membrane.

[0069]

[0070] In this embodiment, n represents the number of structural units of the polymer, and 10≤n≤200.

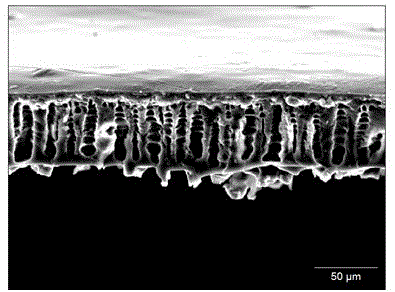

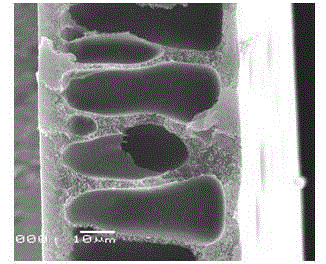

[0071] in figure 1 The cross-sectional electron microscope picture of the solvent-resistant nanofiltration membrane prepared in Example 1 is given. The membrane material shows a traditional finger-like pore structure. The membrane material is used to separate dy...

Embodiment 2

[0078] Dissolve 3.4 grams of phosphorus pentoxide in 34 grams of polyphosphoric acid, add it to a 500 ml three-necked flask, heat up and stir to form a clear solution, then add 6 mmol of biphenyltetramine, 6 mmol of 4,4'-dicarboxy Diphenyl ether, stir and heat up to 200 degrees, after 20 hours of reaction, cool down, pour into 5% sodium hydroxide solution. After standing for 24 hours, wash well with water until the solution is neutral. Filter and dry. The prepared polymer was dissolved in DMAC to prepare a 15wt% solution, and the solution was cast onto a glass plate and flattened with a casting knife. Then quickly immersed in 5L of water, solidified for 5 minutes to form a porous separation membrane to obtain a porous membrane of polybenzimidazole. The porous separation membrane of polybenzimidazole was cross-linked in 5% methanol solution of p-dichlorobenzylbenzene for 24 hours to obtain a solvent-resistant nanofiltration membrane with the following chemical structure.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com