Preparation method of MCM-22 molecular sieve

A technology of MCM-22 and molecular sieve, which is applied in the field of preparation of MCM-22 molecular sieve, can solve problems such as long crystallization time and narrow range of silicon-aluminum ratio, so as to improve production efficiency, broaden the range of silicon-aluminum ratio, and shorten the crystallization reaction the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

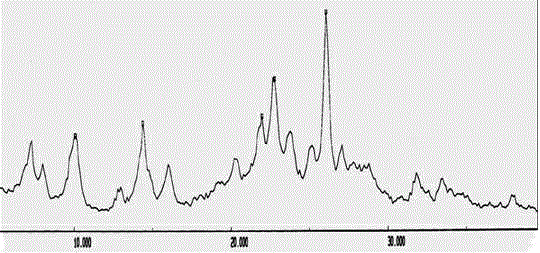

Image

Examples

Embodiment 1

[0023] Take the original powder of MCM-22 (prepared by hydrothermal method, sodium type), the particle size is about 6 μm, SiO 2 / Al 2 O 3 The molar ratio is 20, according to the mass ratio H 2 The ratio of O / MCM-22=40, mix it with distilled water, and then disperse it with 20KHZ ultrasonic wave for 2 hours. Afterwards, the dispersed MCM-22 molecular sieve suspension was placed in a 100 mL measuring cylinder and allowed to settle naturally for 5 hours at room temperature. Take out the upper layer suspension, analyze the content of small grain MCM-22 molecular sieve and water in the suspension, and use it as a part of raw material, then according to SiO 2 / Al 2 O 3 =25、OH - / SiO 2 =0.12,H 2 O / SiO 2 =28 molar ratio, add the above suspension, sodium hydroxide, water, silicic acid, sodium aluminate to make initial sol, wherein the amount of suspension is 1.3% of the initial sol weight based on MCM-22 molecular sieve. When the sol formed a gel, the gel was aged at room te...

Embodiment 2

[0026] Prepare MCM-22 raw powder (hydrogen type) by hydrothermal method, the particle size is about 2 μm, SiO 2 / Al 2 O 3 The molar ratio is 30, according to the mass ratio H 2The ratio of O / MCM-22=70, mix it with distilled water, and then disperse it with 40KHZ ultrasonic wave for 1.5 hours. Afterwards, the dispersed MCM-22 molecular sieve suspension was placed in a 100 mL graduated cylinder at room temperature and allowed to settle naturally for 10 hours. Take out the upper layer suspension, analyze the content of small grain MCM-22 molecular sieve and water in the suspension, and use it as a part of raw material, then according to SiO 2 / Al 2 o 3 =40、OH - / SiO 2 =0.15,H 2 O / SiO 2 =30 molar ratio, add the suspension, sodium hydroxide, water, silica sol, and sodium aluminate to make the initial sol, wherein the amount of the suspension is calculated based on MCM-22 molecular sieve and accounts for 2.5% of the weight of the initial sol. After the sol forms a gel, th...

Embodiment 3

[0029] The sodium type small-grain MCM-22 raw powder prepared by the hydrothermal method has a particle size of about 700nm, and its SiO 2 / Al 2 o 3 The molar ratio is 30, according to the mass ratio H 2 The ratio of O / MCM-22=95, mix it with distilled water, and then disperse it with 80KHZ ultrasonic waves for 0.5 hours. Afterwards, the dispersed MCM-22 molecular sieve suspension was placed in a 100 mL graduated cylinder at room temperature and allowed to settle naturally for 15 hours. Take out the upper layer suspension, analyze the content of small grain MCM-22 molecular sieve and water in the suspension, and use it as a part of raw material, then according to SiO 2 / Al 2 o 3 =80,OH - / SiO 2 =0.17,H 2 O / SiO 2 = 40 molar ratio to add the suspension, sodium hydroxide, water, silicic acid, sodium aluminate to make the initial sol, wherein the amount of the suspension is calculated based on MCM-22 molecular sieve accounted for 4.8% of the weight of the initial sol. Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com