Multi-page rolled type film contactor for removing resolvable gases in water

A roll-type membrane and contactor technology, applied in the direction of degassed water/sewage treatment, etc., can solve the problems of difficult to obtain hollow fiber membrane contactor, complicated equipment operation, long separation time, etc., and achieve compact structure design, large circulation volume Small, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

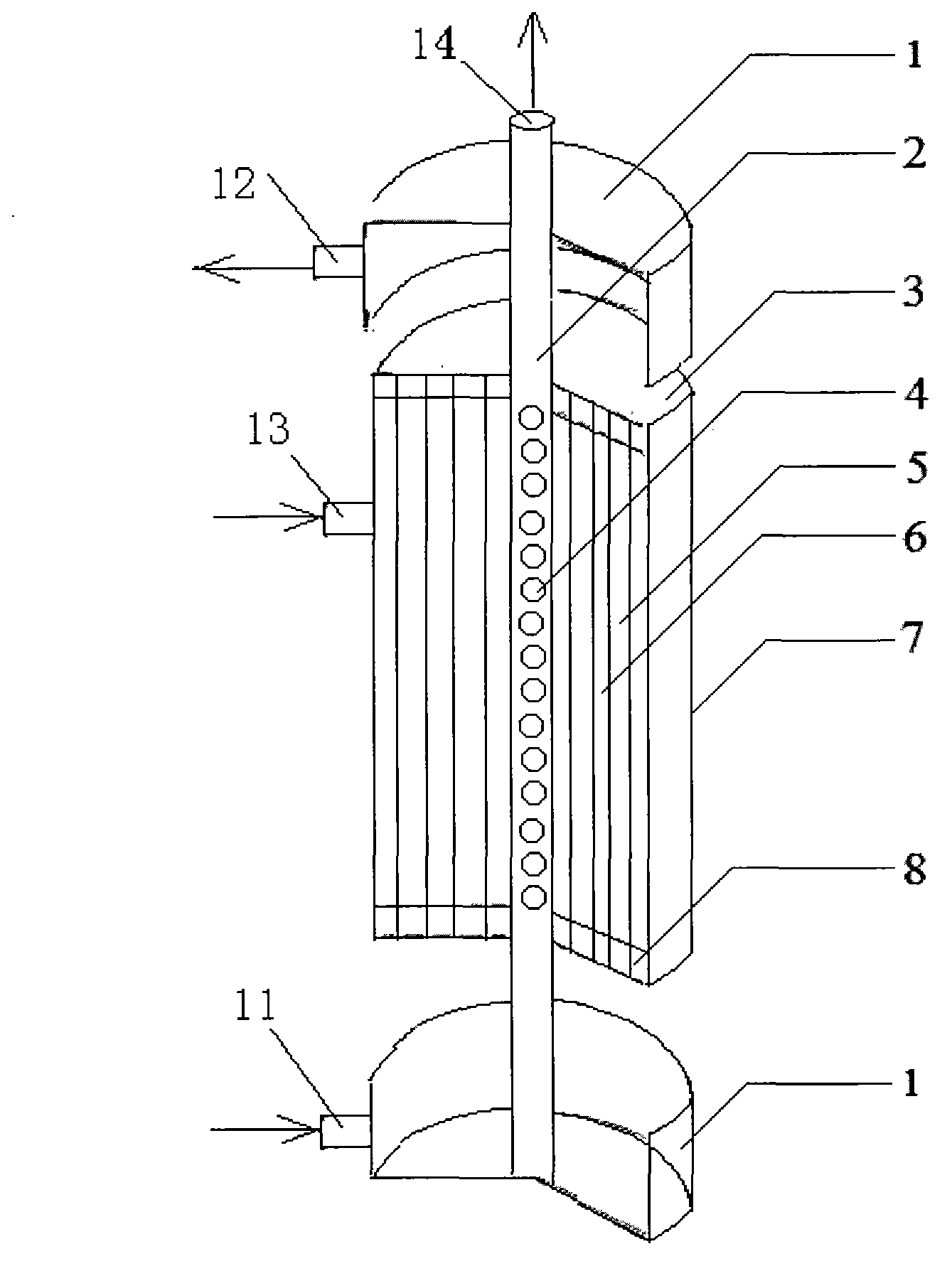

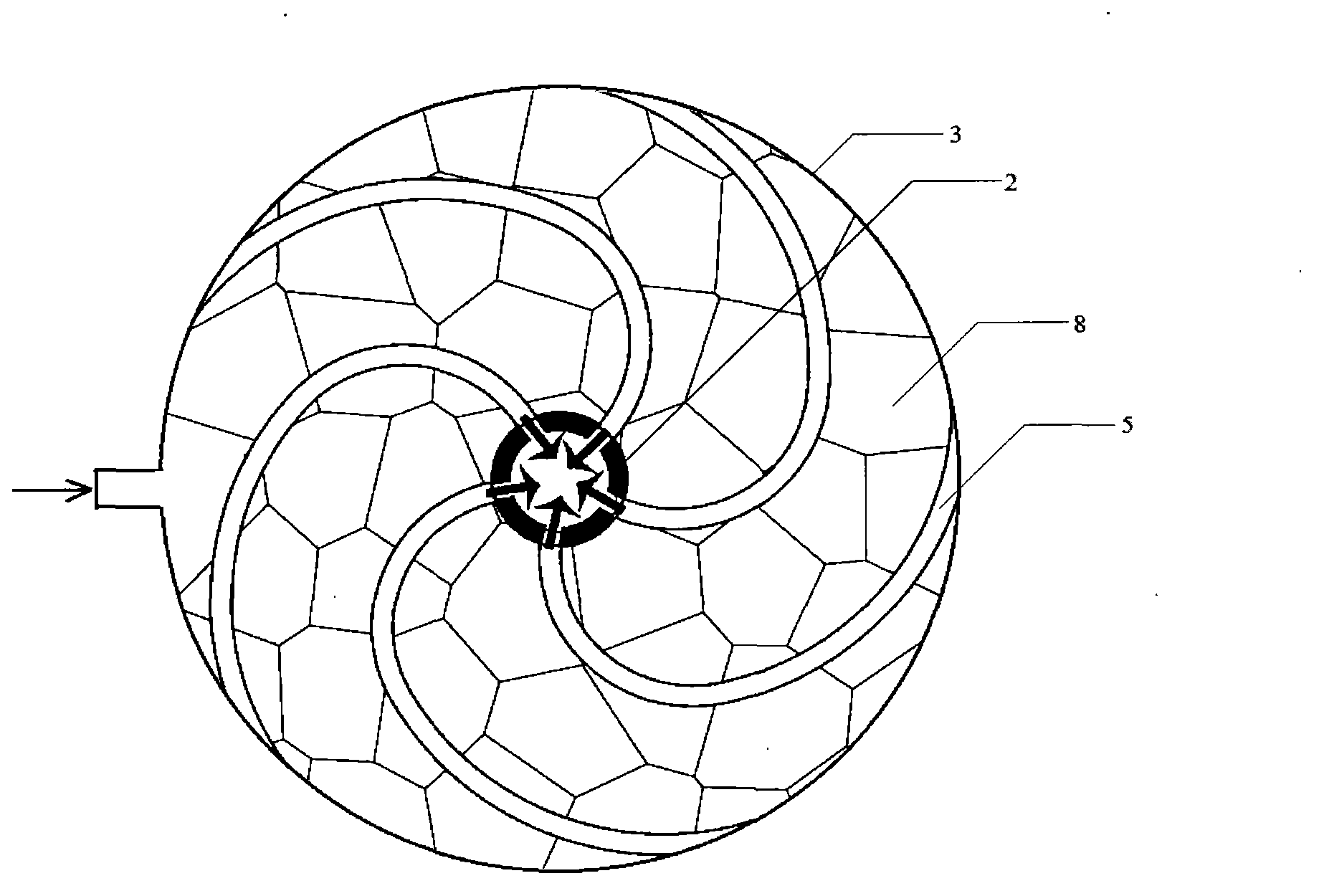

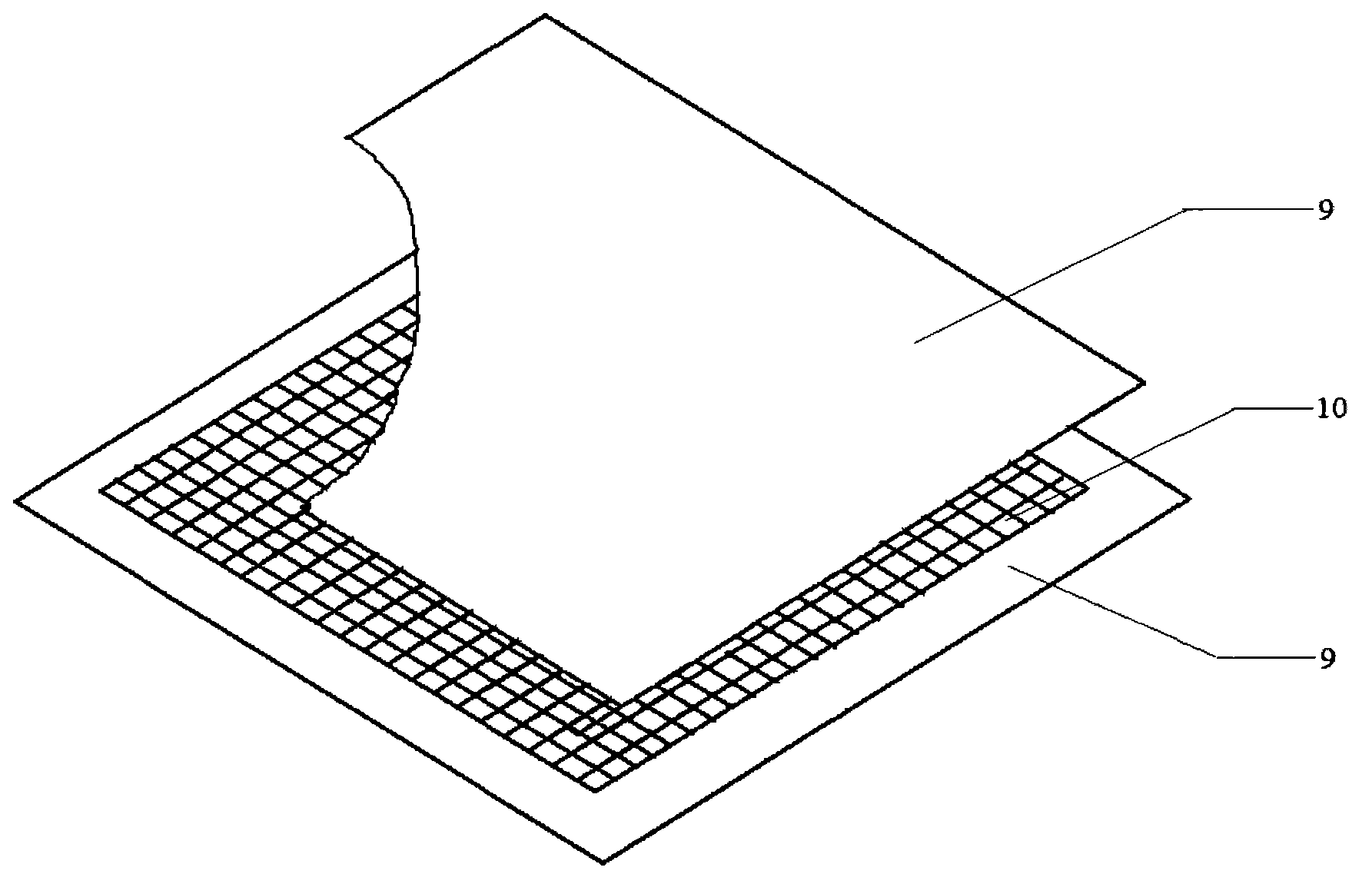

[0019] Embodiment 1: The multi-sheet roll-type membrane contactor involved in the present invention has a cylindrical structure and includes three parts: the membrane core 3 , the tube shell 7 and the shell cover 1 . The membrane core 3 is placed in the tube shell 7 and connected with the tube shell 7 by casting. Shell cover 1 is sewn on pipe shell 7 two ends. The membrane core 3 is formed by rolling a membrane bag 8 around the central tube 2. The membrane bag 8 is formed by superimposing two layers of plate-type microporous membranes 9 and a layer of spacer 10 placed between the two layers of microporous membranes. The length of the net 10 is slightly less than the length of the microporous membrane 9 , and the plate microporous membrane 9 is connected with the surroundings of the partition net 10 . There is an outer layer of mesh between the membrane bag 8 and the membrane bag 8. The inner cavity 6 and the outer cavity 5 are formed inside and outside the membrane bag 8. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com