Water paper paper-making wastewater efficient treatment and comprehensive recycling method and device

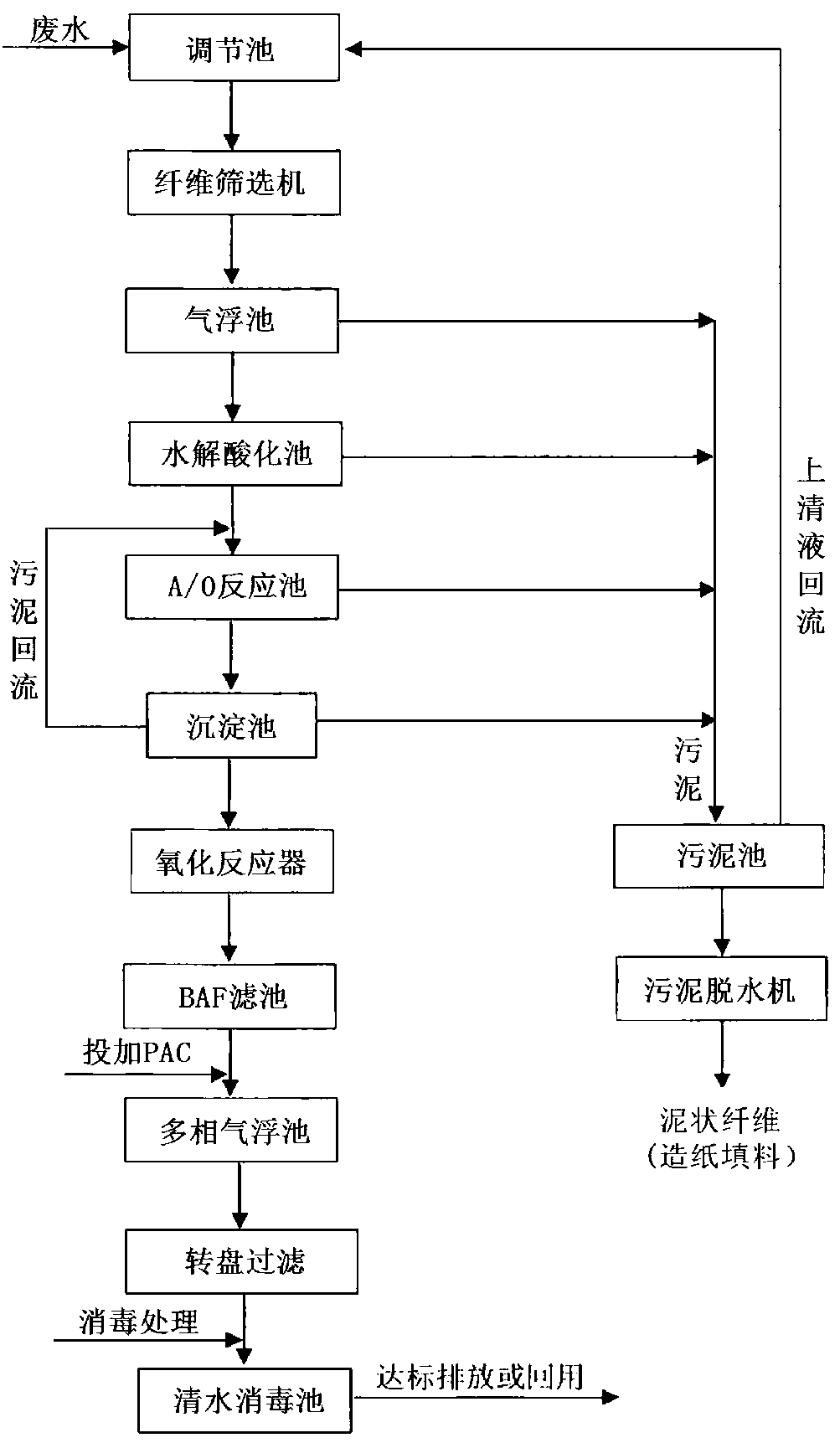

A technology for papermaking and wastewater from waste paper, which is applied in the process of wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. In order to improve the comprehensive treatment effect and reduce the emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

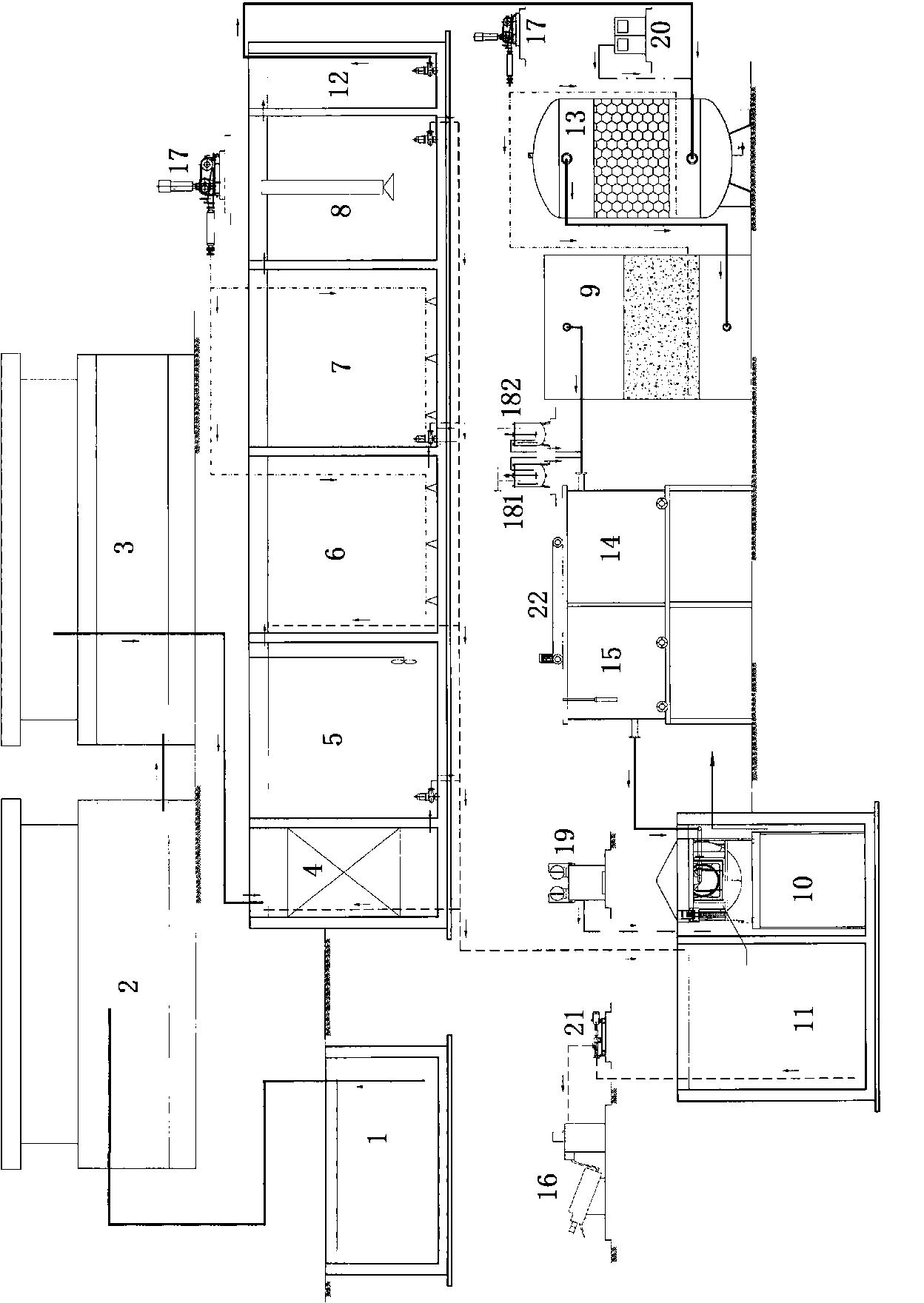

[0048] The waste water is collected into the adjustment tank 1, and after the water quality and quantity are adjusted, the lifting pump is used to lift it to the screening device 2 to remove the fibers in it, and then inject it into the air flotation tank 3 for air flotation treatment. The scum enters the sludge tank 11, and the effluent flows into the hydrolysis acidification tank 4 Carry out hydrolysis, then the effluent enters the anaerobic tank 5 and stays for reaction for 8 hours, then enters the front aerobic tank 6 and the rear aerobic tank 7 and stays for 16 hours, performs anaerobic-aerobic treatment, and the effluent enters the sedimentation tank 8 for precipitation treatment, The settled sludge is regularly discharged into the sludge tank 11, and the supernatant is discharged into the intermediate tank 12 to adjust the water quantity and quality; the effluent from the intermediate tank 12 is injected into the oxidation reactor 13, and the ozone generated by the oxidat...

Embodiment 2

[0050] The waste water is lifted by the lifting pump to the screening device 2 to remove the fibers therein, and then injected into the air flotation tank 3 for air flotation treatment, the scum enters the sludge tank 11, the effluent flows into the hydrolysis acidification tank 4 for hydrolysis, and then the effluent enters the anaerobic tank 5 to stay React for 19 hours, then enter the front aerobic tank 6 and the rear aerobic tank 7 to stay for 53 hours, perform anaerobic-aerobic treatment, the effluent enters the sedimentation tank 8 for sedimentation treatment, and the settled sludge is regularly discharged to the sludge tank 11 , the supernatant is discharged into the intermediate pool 12 to mix the water volume and water quality; the intermediate pool 12 effluent is injected into the advanced oxidation reactor 13, and the ozone generated by the oxidation generator 20 is passed into the wastewater in the oxidation reactor 13 for oxidative decomposition for 12 hours, and th...

Embodiment 3

[0052] The waste water is lifted by the lifting pump to the screening device 2 to remove the fibers therein, and then injected into the air flotation tank 3 for air flotation treatment, the scum enters the sludge tank 11, the effluent flows into the hydrolysis acidification tank 4 for hydrolysis, and then the effluent enters the anaerobic tank 5 to stay React for 15 hours, then enter the front aerobic tank 6 and the rear aerobic tank 7 to stay for 35 hours, perform anaerobic-aerobic treatment, the effluent enters the sedimentation tank 8 for sedimentation treatment, and the settled sludge is regularly discharged to the sludge tank 11 , the supernatant is discharged into the intermediate pool 12 to adjust the water volume and water quality; the intermediate pool 12 effluent is injected into the oxidation reactor 13, and the ozone generated by the oxidation generator 20 is passed into the wastewater in the oxidation reactor 13 for oxidative decomposition for 2 hours, and the efflu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com