Method for preparing methyl silicate and aluminum fluoride from silicon tetrafluoride and methanol

A technology of silicon tetrafluoride and methyl silicate, applied in the chemical industry, can solve problems such as unreasonable utilization of silicon tetrafluoride, achieve high environmental value and economic value, simple steps, and economical and reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

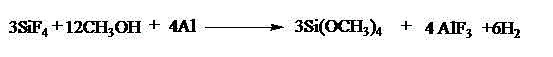

Image

Examples

Embodiment 1

[0020] 1040 g of silicon tetrafluoride methanol solution with a mass fraction of 10% and 50 g of aluminum powder with a particle size of 75 microns were added to the synthesis reactor, and the temperature was gradually raised to 30 °C for 6 hours of reaction. After the reaction was completed, the product was subjected to vacuum filtration to obtain a solid and a filtrate. The solid was washed with anhydrous methanol to obtain the target product anhydrous aluminum fluoride. The excess methanol was distilled off from the filtrate to obtain methyl silicate with a high boiling point.

Embodiment 2

[0022] 434 g of silicon tetrafluoride methanol solution with a mass fraction of 24% and 50 g of aluminum powder with a particle size of 13 microns were added to the synthesis reactor, and the temperature was gradually raised to 30 °C for 1 h of reaction. After the reaction was completed, the product was subjected to vacuum filtration to obtain a solid and a filtrate. The solid was washed with anhydrous methanol to obtain the target product anhydrous aluminum fluoride. The excess methanol was distilled off from the filtrate to obtain methyl silicate with a high boiling point.

Embodiment 3

[0024] 743 g of silicon tetrafluoride methanol solution with a mass fraction of 14% and 50 g of aluminum powder with a particle size of 75 microns were added to the synthesis reactor, and the temperature was gradually raised to 30 °C for 6 hours of reaction. After the reaction was completed, the product was subjected to vacuum filtration to obtain a solid and a filtrate. The solid was washed with anhydrous methanol to obtain the target product anhydrous aluminum fluoride. The excess methanol was distilled off from the filtrate to obtain methyl silicate with a high boiling point.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com