Method for preparing acylated casein by taking yak milk casein as raw material

A technology for milk casein and casein, which is applied in the field of preparing acylated casein, can solve the problems of the physicochemical, sensory, emulsifying, gelling, stability and other functional properties of tyra casein products, and can meet different industrial processing requirements. Demand, increase in hydrophilicity, and the effect of expanding the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

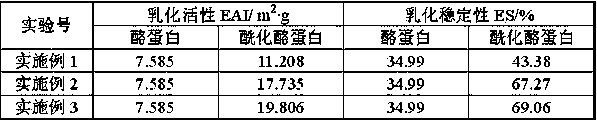

Embodiment 1

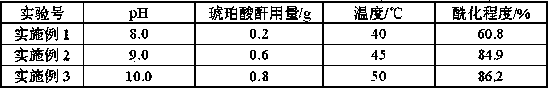

[0024] Example 1 A method for preparing acylated casein from yak milk casein, comprising the following steps:

[0025] ⑴Preparation of casein solution: Dissolve casein in deionized water at a mass-to-volume ratio (g / mL) of 1:50, stir magnetically at 30°C until casein is completely dissolved, and pass 1.0mol L -1 The sodium hydroxide solution adjusts the pH value to stabilize it at 6.5 to obtain a casein solution.

[0026] (2) Acylation: through 1.0mol·L -1 sodium hydroxide solution to adjust the pH value of the casein solution to 8.0, add solid succinic anhydride several times, carry out succinylation at 40°C with constant temperature magnetic stirring, and continue to stir for 50 minutes after all the succinic anhydride is added to make it fully React to obtain acylated casein solution; the mass ratio (g / g) of succinic anhydride to casein is 0.2:1.

[0027] (3) Acylated casein products: use 1.0 mol L -1 hydrochloric acid solution to adjust the pH value of the acylated case...

Embodiment 2

[0028] Example 2 A method for preparing acylated casein from yak milk casein, comprising the following steps:

[0029] ⑴Preparation of casein solution: Dissolve casein in deionized water at a material-to-liquid mass-volume ratio (g / mL) of 1:150, stir magnetically at 40°C until the casein is completely dissolved, and pass through 1.0mol L -1 The sodium hydroxide solution adjusts the pH value to stabilize it at 7.5 to obtain a casein solution.

[0030] (2) Acylation: through 1.0mol·L -1 sodium hydroxide solution to adjust the pH value of the casein solution to 10.0, add solid succinic anhydride several times, carry out succinylation at 50°C with constant temperature magnetic stirring, and continue stirring for 30 minutes after all the succinic anhydride is added to make it fully reaction to obtain acylated casein solution; the mass ratio (g / g) of succinic anhydride to casein is 0.8:1.

[0031] (3) Acylated casein products: use 1.0 mol L -1 hydrochloric acid solution to adjust...

Embodiment 3

[0032] Example 3 A method for preparing acylated casein from yak milk casein, comprising the following steps:

[0033] ⑴Preparation of casein solution: Dissolve casein in deionized water at a mass-to-volume ratio (g / mL) of 1:100, stir magnetically at 35°C until casein is completely dissolved, and pass 1.0mol L -1 The sodium hydroxide solution was used to adjust the pH value to stabilize it at 7.0 to obtain a casein solution.

[0034] (2) Acylation: through 1.0mol·L -1sodium hydroxide solution to adjust the pH value of the casein solution to 9.0, add solid succinic anhydride several times, carry out succinylation at 45°C with constant temperature magnetic stirring, and continue stirring for 40 minutes after all the succinic anhydride is added to make it fully React to obtain acylated casein solution; the mass ratio (g / g) of succinic anhydride to casein is 0.6:1.

[0035] (3) Acylated casein products: use 1.0 mol L -1 hydrochloric acid solution to adjust the pH value of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com