Method for improving yeast beta-D-glucan water-solubility

A dextran and water-soluble technology, which is applied in the field of improving the water solubility of yeast β-glucan by using ionic liquids, can solve the problems of high production cost, damage, and low yield of soluble glucan, and achieve industrial scale production , The effect of simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

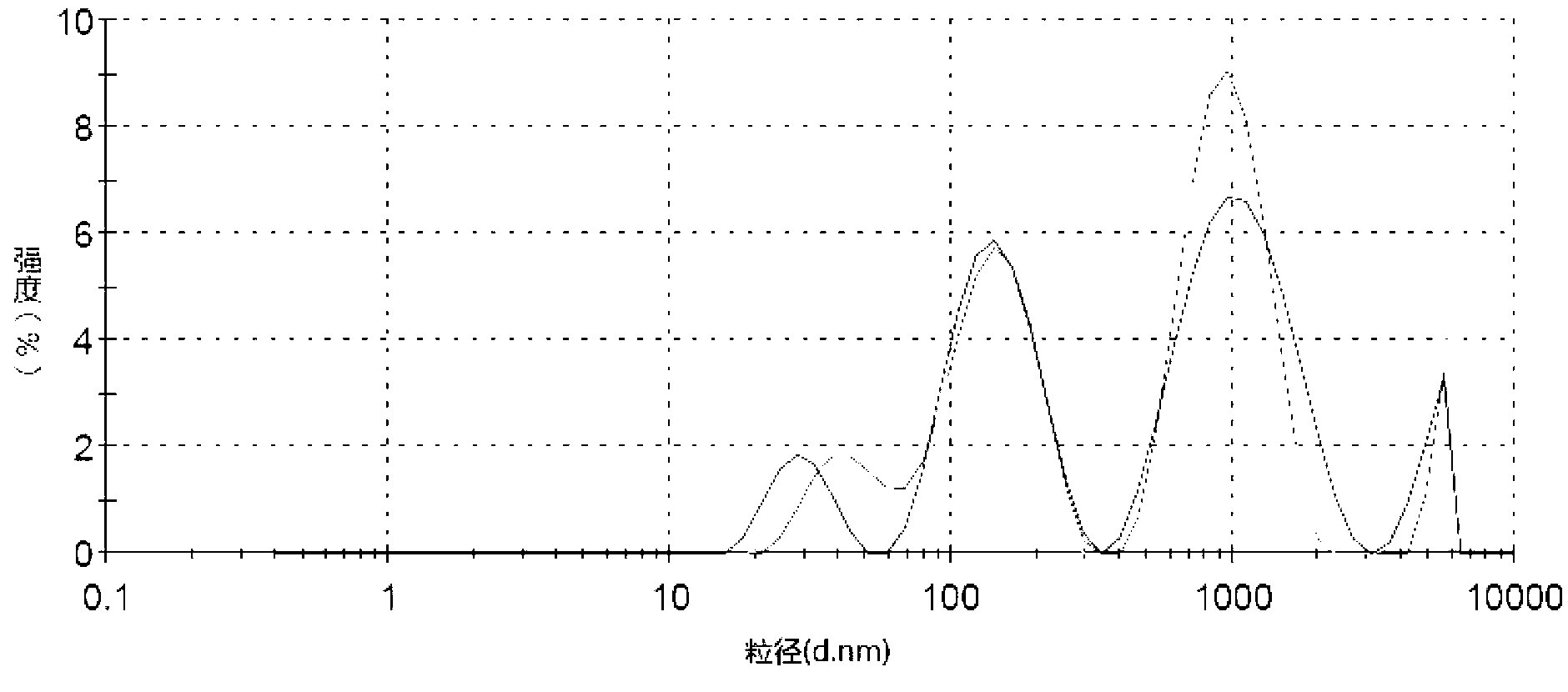

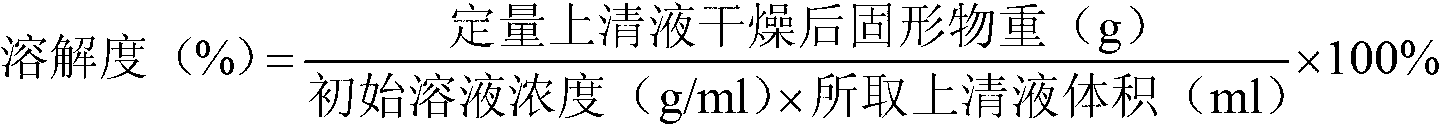

[0033] Example 1. Modified solubilized yeast β-D-glucan

[0034] (1) Add yeast β-D-glucan to 1-ethyl-3-methylimidazole acetate ionic liquid, and heat to 85°C until yeast β-D-glucan is completely dissolved in the ionic liquid , To obtain a glucan-ionic liquid mixed solution, in which the mass percentage of yeast β-glucan is 0.5%;

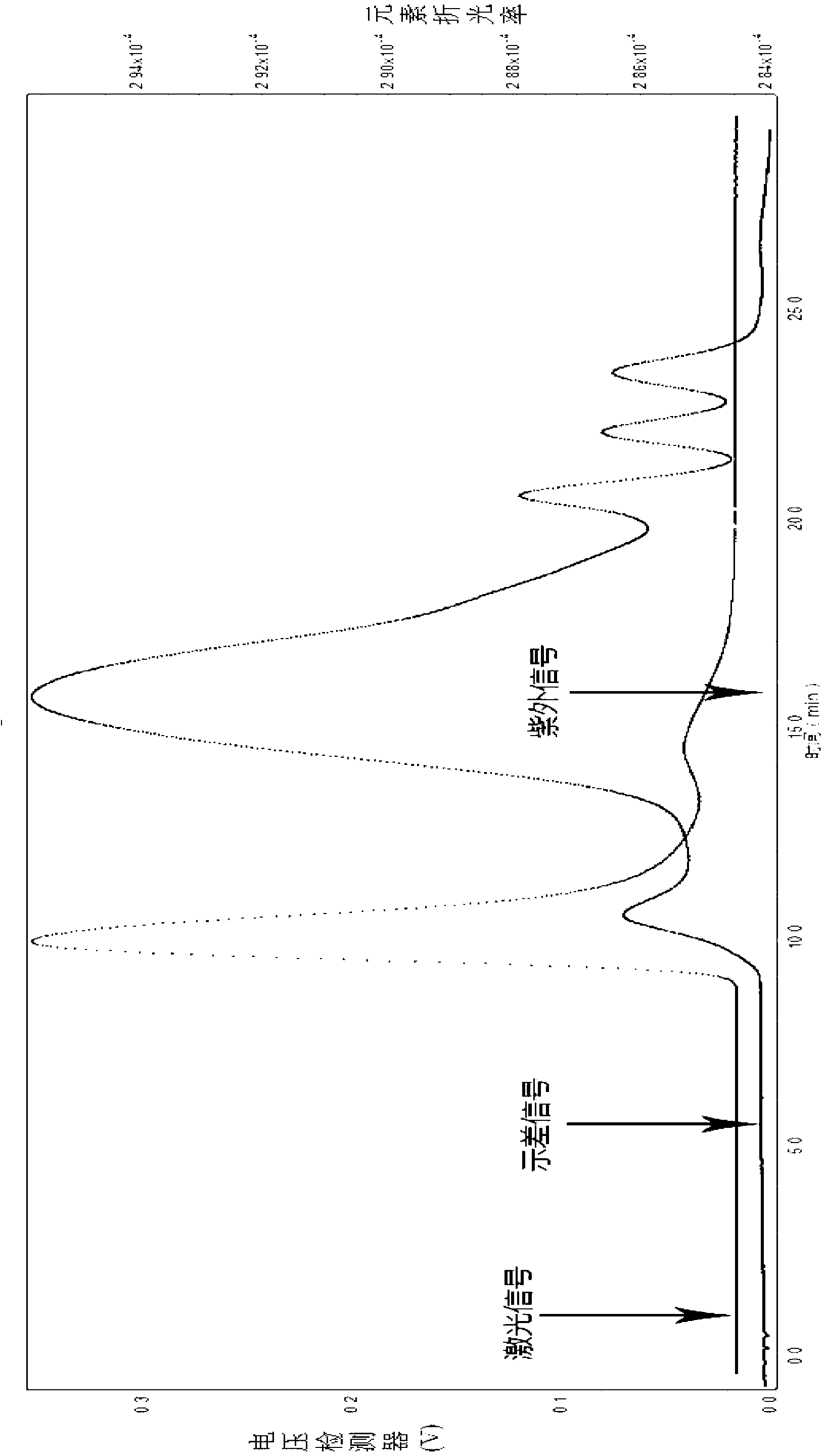

[0035] (2) The dextran-ionic liquid mixed solution obtained in step (1) is subjected to micro-jet homogenization treatment with a high-pressure micro-jet homogenizer, and the pressure of the micro-jet homogenization treatment is controlled to 170 MPa and the treatment flow rate is 22 mL / min;

[0036] (3) Precipitate the dextran in the dextran-ionic liquid mixed solution after the high-pressure micro-jet homogenization treatment in step (2) with ethanol, and the volumetric amount of ethanol is that of the dextran-ionic liquid mixed solution Precipitate at 4°C for 24h, then centrifuge and evaporate to remove the ethanol in the supernatant, and then heat and ...

Embodiment 2

[0044] Example 2: Modified solubilized yeast β-glucan

[0045] (1) Add yeast β-D-glucan to 1-ethyl-3-methylimidazole acetate ionic liquid, and heat to 85°C until yeast β-D-glucan is completely dissolved in the ionic liquid , To obtain a glucan-ionic liquid mixed solution, in which the mass percentage of yeast β-glucan is 1.0%;

[0046] (2) The dextran-ionic liquid mixed solution obtained in step (1) is subjected to micro-jet homogenization treatment with a high-pressure micro-jet homogenizer, and the pressure of the micro-jet homogenization treatment is controlled to be 140 MPa and the treatment flow rate is 30 mL / min;

[0047] (3) Precipitate the dextran in the dextran-ionic liquid mixed solution after the homogenization of the high-pressure micro-jet in step (2) with ethanol, and the volumetric amount of ethanol is that of the dextran-ionic liquid mixed solution 3 times, precipitate at 25°C for 5h, then centrifuge, rotary evaporate to remove the ethanol in the supernatant, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com