High-solid-content photocuring fluorinated polyurethane-acrylate (PFUA) coating and preparation method thereof

A polyacrylate and acrylate technology, used in polyurea/polyurethane coatings, coatings, etc., can solve the problems of inability to water-based, slow curing speed, difficult photocuring efficiency, etc., and achieve small molecular weight distribution and moderate molecular weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

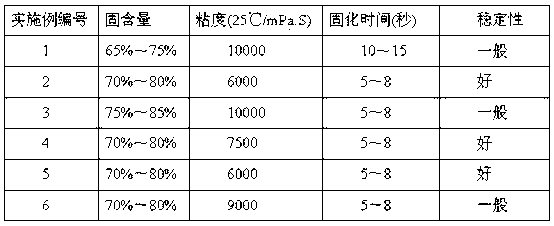

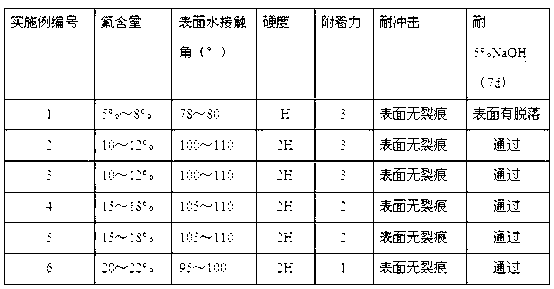

Examples

Embodiment 1

[0033] A high-solid light-curing fluorine-containing polyurethane-polyacrylate coating (PFUA) and a preparation method thereof provided in Example 1 of the present invention include the following steps:

[0034] S1. Preparation of hydroxy fluorinated polyacrylate resin

[0035] In parts by weight, place 2 parts azobisisobutyronitrile, 18 parts methyl methacrylate, 5 parts butyl acrylate, 11 parts hexafluorobutyl methacrylate and 13 parts hydroxyethyl methacrylate The beaker is evenly mixed and transferred to a constant pressure funnel.

[0036] Place 20 parts of butyl acetate solution in a four-necked flask, infuse with nitrogen protection, heat the temperature to 120℃ through a heating mantle to ensure the solvent reflux, turn on the stirring; through the constant pressure funnel, slowly and continuously add the uniformly mixed monomer, 1 The dripping is completed within hours. After the dripping is completed, the reaction temperature is maintained, and the reaction is continued f...

Embodiment 2

[0044] A high-solid light-curing fluorine-containing polyurethane-polyacrylate coating (PFUA) and a preparation method thereof, including the following steps:

[0045] S1. Preparation of hydroxy fluorinated polyacrylate resin

[0046] In parts by weight, mix 2 parts of initiator azobisisobutyronitrile, 10 parts of butyl acrylate, 12 parts of hexafluorobutyl methacrylate, 12 parts of dodecafluoroheptyl methacrylate and 13 parts of methacrylic acid Place the hydroxyethyl ester in a beaker and mix well and transfer it into a constant pressure funnel.

[0047] Put 15 parts of solvent (butyl acetate) in a four-necked flask, pass nitrogen protection, heat the temperature to 110℃~120℃ through a heating mantle to ensure the solvent reflux, turn on the stirring; through the constant pressure funnel, slowly and continuously add dropwise and mix well The monomer is added dropwise in 1 hour. After the dropwise addition is complete, keep the reaction temperature and continue the reaction for 3 h...

Embodiment 3

[0055] A high-solid light-curing fluorine-containing polyurethane-polyacrylate coating (PFUA) and a preparation method thereof, including the following steps:

[0056] S1. Preparation of hydroxy fluorinated polyacrylate resin

[0057] In parts by weight, combine 2 parts of initiator azobisisobutyronitrile and 2 parts of initiator benzoyl peroxide, 10 parts of butyl acrylate, 24 parts of dodecafluoroheptyl methacrylate and 10 parts of hydroxyethyl acrylate Place the ester in a beaker and mix well and transfer it to a constant pressure funnel.

[0058] Place 10 parts of solvent (butyl acetate) in a four-necked flask, pass nitrogen protection, use a heating mantle to heat the temperature to 120℃ to ensure the solvent reflux, turn on the stirring; through the constant pressure funnel, slowly and continuously add the uniform monomer dropwise , The dripping is complete in 1 hour. After the dripping is complete, keep the reaction temperature and continue the reaction for 2 hours; stop heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com