Tourmaline electret polylactic acid melt-blown non-woven cloth and manufacture method

A technology of melt-blown nonwovens and polylactic acid, which is applied in the direction of nonwovens, textiles and papermaking, and single-component polyester rayon, which can solve the problem of reduced stability of surface charge dissipation and filtration performance, and material electret effect Poor, difficult processing and other problems, to achieve the effect of easy operation, improved filterability, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Place the polylactic acid masterbatch in a vacuum drying oven, dry at 90°C for at least 8 hours, add tourmaline with a mass ratio of 1% polylactic acid content, and add a coupling agent with a mass ratio of 3% tourmaline content and account for the mass of tourmaline 1% dispersant and diluent 3 times the mass of coupling agent. The coupling agent is preferably titanate, the dispersant is preferably PE wax, and the diluent is preferably glycerol. The tourmaline-modified polylactic acid slice 1# was prepared according to the above-mentioned pre-blending and melt-blending methods, ready for use.

Embodiment 2

[0025]Place the polylactic acid masterbatch in a vacuum drying oven, dry at 90°C for at least 8 hours, add tourmaline with a mass ratio of 2% polylactic acid content, and add a coupling agent with a mass ratio of 3% tourmaline content and a mass ratio of Dispersant with 2% tourmaline content and diluent with 3 times mass of coupling agent. The coupling agent is preferably titanate, the dispersant is preferably PE wax, and the diluent is preferably glycerol. The tourmaline-modified polylactic acid chip 2# was prepared according to the above-mentioned pre-blending and melt-blending methods and was ready for use.

Embodiment 3

[0027] Place the polylactic acid masterbatch in a vacuum drying oven, dry at 90°C for at least 8 hours, add tourmaline with a mass ratio of 3% polylactic acid content, and add a coupling agent with a mass ratio of 2% tourmaline content and a mass ratio of The content of tourmaline is 3% dispersant and diluent 3 times the mass of coupling agent. The coupling agent is preferably titanate, the dispersant is preferably PE wax, and the diluent is preferably glycerol. The tourmaline-modified polylactic acid chip 3# was prepared by the above-mentioned pre-blending and melt-blending methods and was ready for use.

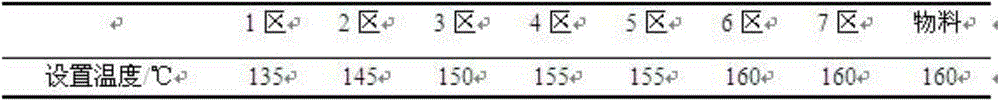

[0028] The raw materials mixed by the high-speed mixer are melt-blended with a twin-screw extruder. The temperature settings of each section of the twin-screw extruder are shown in Table 1.

[0029] Table 1 Temperature settings in each zone of the screw extruder

[0030]

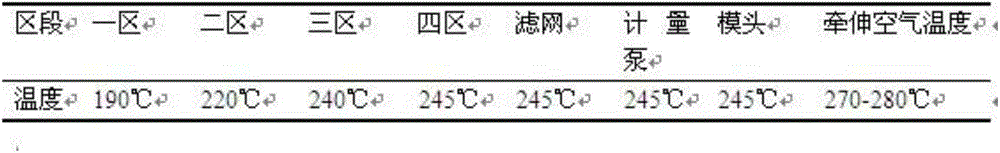

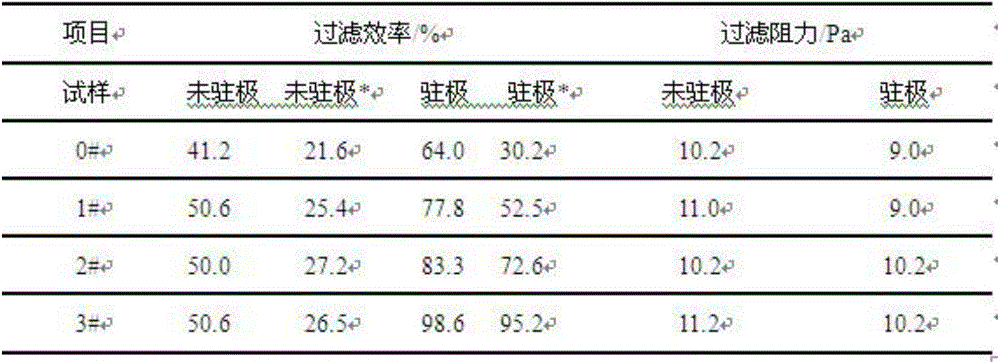

[0031] The tourmaline-modified polylactic acid chips prepared above were used to prepare melt-bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber diameter | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com