Dual-purpose tool as drill stem and well completion sieve tube

A drill string and screen technology, applied in drill pipes, drilling equipment, drill pipes, etc., can solve the problems of many hidden dangers, stuck drilling, economic losses, etc., to shorten the drilling and completion cycle, improve strength, and reduce accidents. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiment of the present invention is described below in conjunction with accompanying drawing:

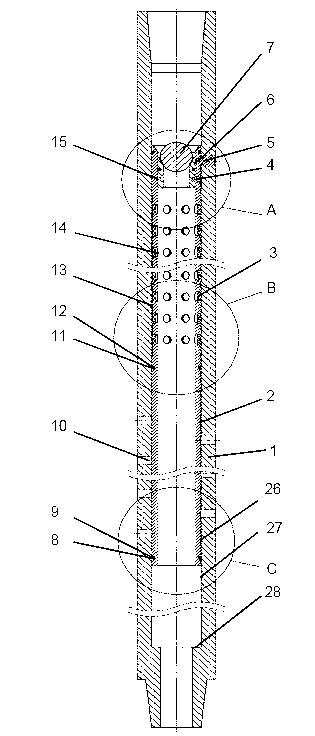

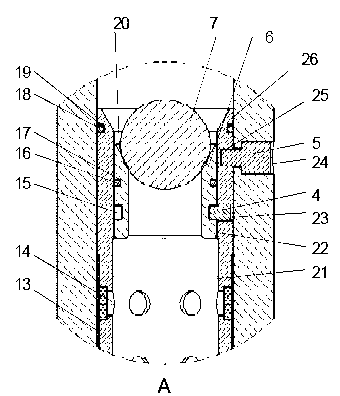

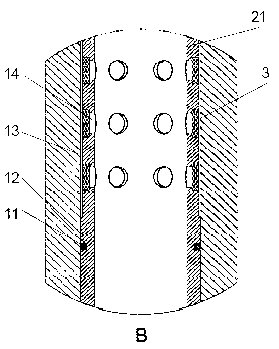

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a drill string and completion screen dual-purpose tool of the present invention mainly consists of a drill string body 1, a screen body 2, a screen 3, a second-stage shear pin 4, a first-stage shear pin 5, The valve seat body 6 and the ball valve 7 are composed.

[0023] Such as figure 1 , Figure 4 and Figure 6 As shown, the drill string body 1 is composed of a drill string hole 10, a first-stage pin hole 24 of the drill string body, a primary inner diameter 26 of the drill string body, a secondary inner diameter 27 of the drill string body and an inner shoulder 28 of the drill string body; The drill string hole 10 is made up of a series of radial spiral holes on the drill string body 1; the secondary internal diameter 27 of the drill string body is slight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com