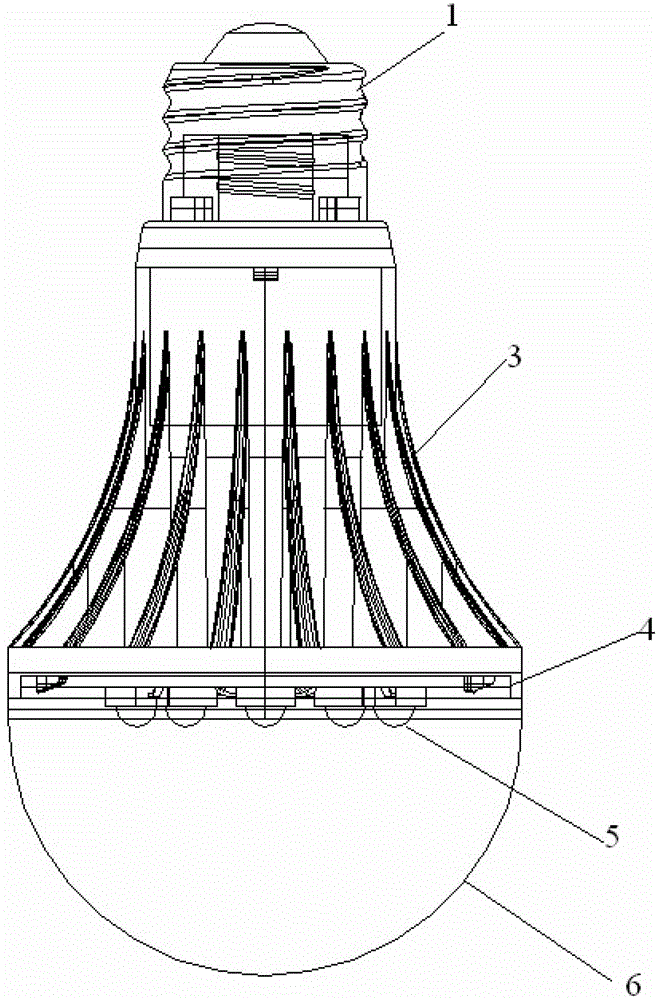

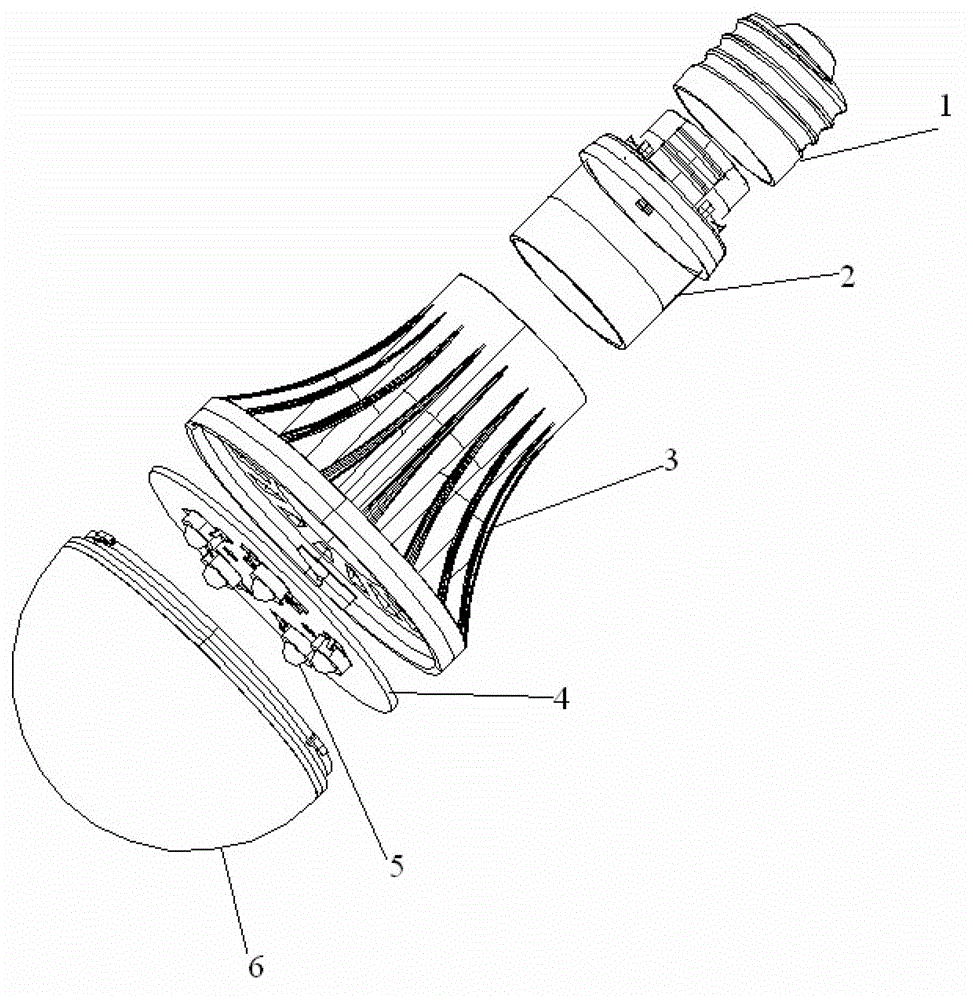

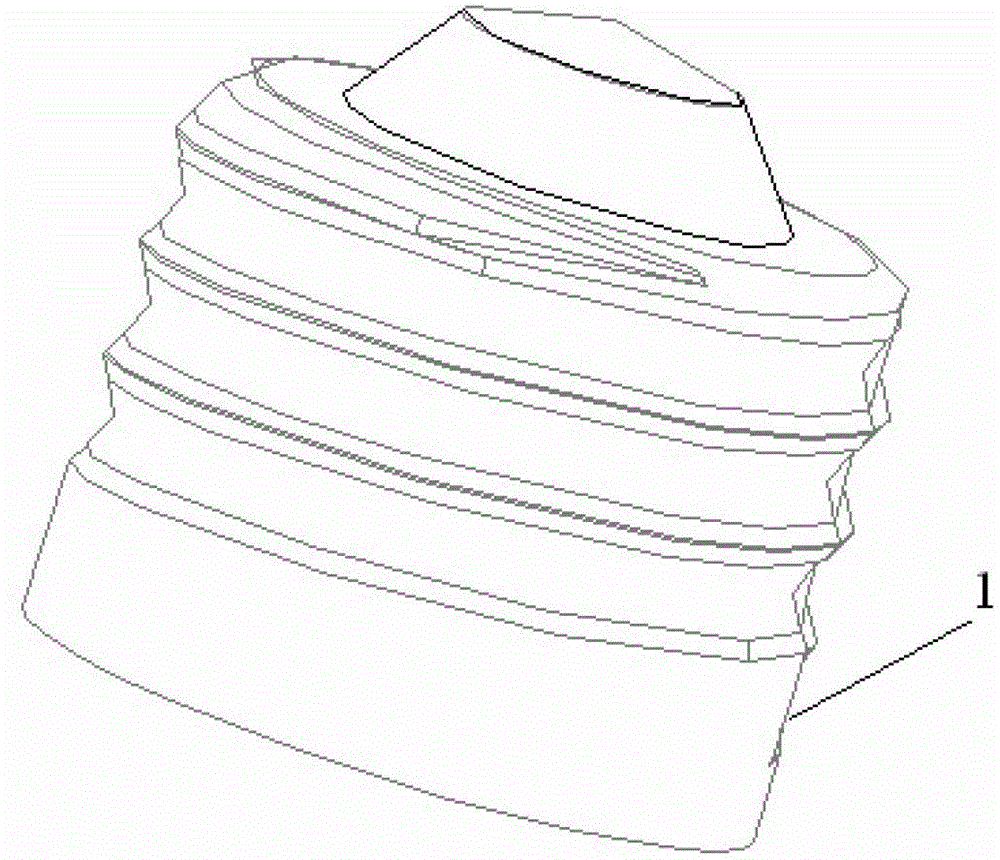

Light-emitting diode (LED) lamp bulb and installing method thereof

A technology for LED bulbs and LED lamp beads, which is applied in lighting devices, lighting device parts, lighting device cooling/heating devices, etc. The effect of improving efficiency, high production efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Embodiment 1: The ABS used in the embodiment of the present invention is a terpolymer of acrylonitrile, butadiene and styrene, A represents acrylonitrile, B represents butadiene, and S represents styrene; wherein, acrylonitrile accounts for 25% ~30%, butadiene accounts for 16%~28%, and styrene accounts for 45%~60%.

[0074] The nano high thermal conductivity composite plastic of the present invention, the filler included in the preparation raw material is one or more of the following compounds (or mixtures): MgO, Al 2 o 3 、Si 3 N 4 , BN, high-purity carbon powder, AlN, CuO, KAl(SO 4 ) 2 12H 2 O (alum), Al 2 o 3 -2SiO2 2 -2H 2 O (kaolin).

Embodiment 2

[0075] Embodiment 2: The MgO used in the embodiment of the present invention is nano MgO particles.

[0076] The industrial production process of nano powder materials requires simple preparation methods, suitable production costs, good repeatability, uniform powder particle size, high product purity and low agglomeration degree. There are many methods for synthesizing nano-magnesia in the prior art, but few of them can actually be applied to industrial production. One is because of problems such as equipment, cost, raw materials, scale, and investment; the other is that some processes are still in the laboratory research stage, and it is difficult to realize industrialized production, and some are even impossible to realize industrialized production.

[0077] In this example, MgO particles were prepared by a solid-phase method at room temperature.

[0078] The room-temperature solid-phase synthesis method of the present invention overcomes the agglomeration problem existing ...

Embodiment 3-1

[0080] Embodiment 3-1: Si used in the embodiment of the present invention 3 N4 It is nano-silicon nitride particles and meets the following indicators:

[0081]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com