Method for determining arsenic content of plants

A measurement method and plant technology, applied in the field of determination of content, can solve the problems of high experimental conditions, long time consumption, pollution of the environment, etc., and achieve the effect of improving the digestion process, short time required, and low NO2 amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

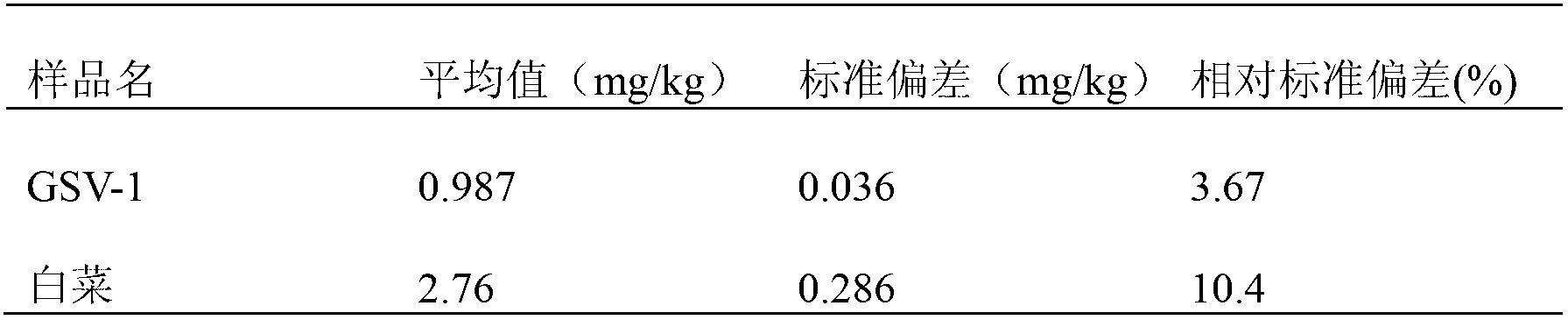

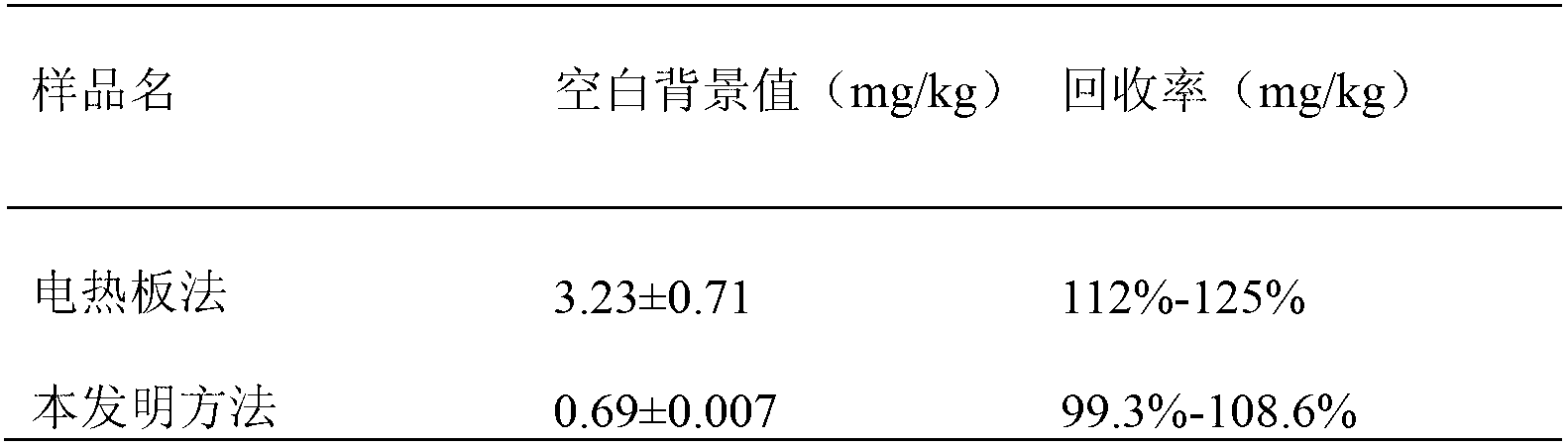

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with embodiments. Although the present invention will be described in conjunction with preferred embodiments, it should be understood that this does not mean that the present invention is limited to the embodiments. On the contrary, the present invention will cover alternatives, improvements, and equivalents that can be included within the scope of the present invention as defined by the appended claims.

[0012] Plant sample preparation: The plant sample is dried, crushed and passed through a 100-mesh sieve.

[0013] Sample digestion: Weigh 0.5g of a plant sample with 100 meshes and place it in a 50mL graduated glass colorimetric tube with stopper, add 5mL premium grade pure concentrated nitric acid 5mL, cover and soak overnight, and make a sample-free reagent blank. The next day, sterilize in a water bath at 100°C for 2 hours.

[0014] Sample to drive acid: Take out the colorimetric tube from the water ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com