Method for phosphogypsum harmless treatment and conversion into regeneration gypsum resource

A technology of harmless treatment and phosphogypsum, applied in the field of phosphogypsum treatment, can solve the problems of increasing production cost and one-time investment of production enterprises, high secondary pollution and pretreatment cost, affecting discharge and utilization, etc., and achieves low treatment cost. , the effect of protecting the environment and less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Configure phosphogypsum modifier, including a specific surface area of 500m 2 / kg of superfine cement clinker powder, the specific surface area is 500m 2 The calcium carbonate micropowder of / kg and the alum solution of 50% concentration; The quality of described alum solution accounts for 3% of phosphogypsum modifier; The mass ratio of described superfine cement clinker micropowder, calcium carbonate micropowder is 3: 7.

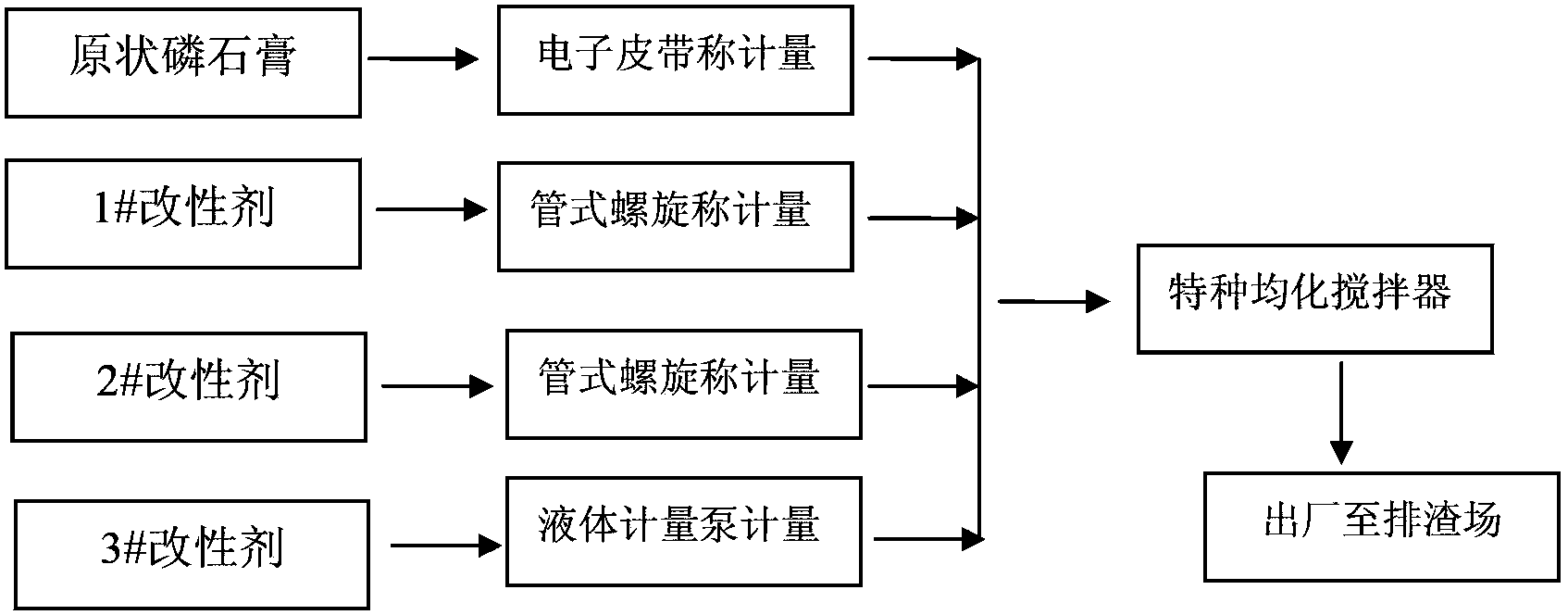

[0022] Install a special homogenizing mixer at the phosphogypsum discharge outlet. The special homogenizing agitator includes a cylinder body provided with a material inlet and a material outlet, a vibrating sleeve arranged in the cylinder body, a mixing mechanism arranged in the sleeve, and a mixing mechanism corresponding to the mixing mechanism. The connected drive mechanism, the electronic control device connected to this drive mechanism.

[0023] The phosphogypsum modifier and the freshly discharged original phosphogypsum are mixed in a mass...

Embodiment 2

[0040] Configure phosphogypsum modifier, including a specific surface area of 300m 2 / kg ultra-fine cement clinker powder, the specific surface area is 300m 2 The calcium carbonate micropowder of / kg and the alum solution of 50% concentration; The quality of described alum solution accounts for 5% of phosphogypsum modifier; The mass ratio of described ultrafine cement clinker micropowder, calcium carbonate micropowder is 1.

[0041] Install a special homogenizing mixer at the phosphogypsum discharge outlet. The special homogenizing agitator includes a cylinder body provided with a material inlet and a material outlet, a vibrating sleeve arranged in the cylinder body, a mixing mechanism arranged in the sleeve, and a mixing mechanism corresponding to the mixing mechanism. The connected drive mechanism, the electronic control device connected to this drive mechanism.

[0042] The phosphogypsum modifier and the freshly discharged original phosphogypsum are mixed in a mass rati...

Embodiment 3

[0045] Install a special homogenizing mixer at the phosphogypsum discharge outlet. The special homogenizing agitator includes a cylinder body provided with a material inlet and a material outlet, a vibrating sleeve arranged in the cylinder body, a mixing mechanism arranged in the sleeve, and a mixing mechanism corresponding to the mixing mechanism. The connected drive mechanism, the electronic control device connected to this drive mechanism.

[0046] Set the specific surface area to 400m 2 / kg ultra-fine cement clinker powder and freshly discharged original phosphogypsum are mixed in a mass ratio of 2:8, sent to a special homogenizer for homogenization and mixing, and then sent to a phosphogypsum slag yard for stacking after compression molding.

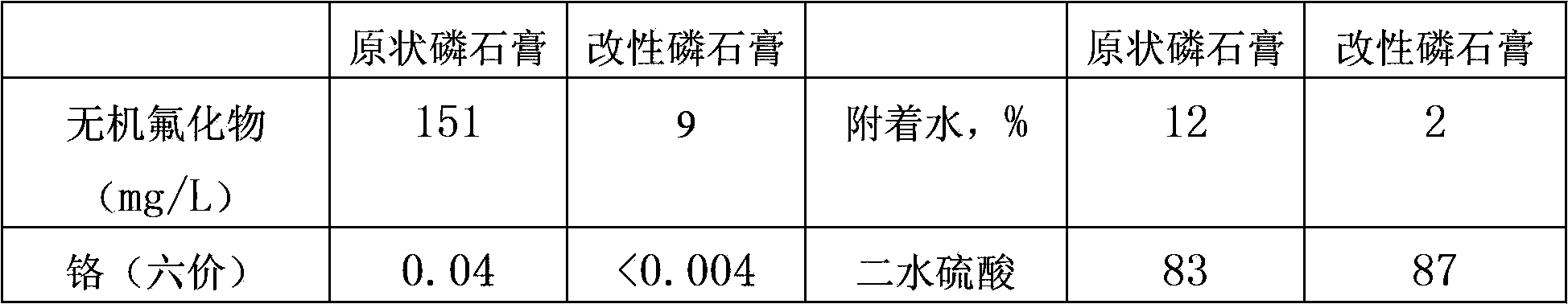

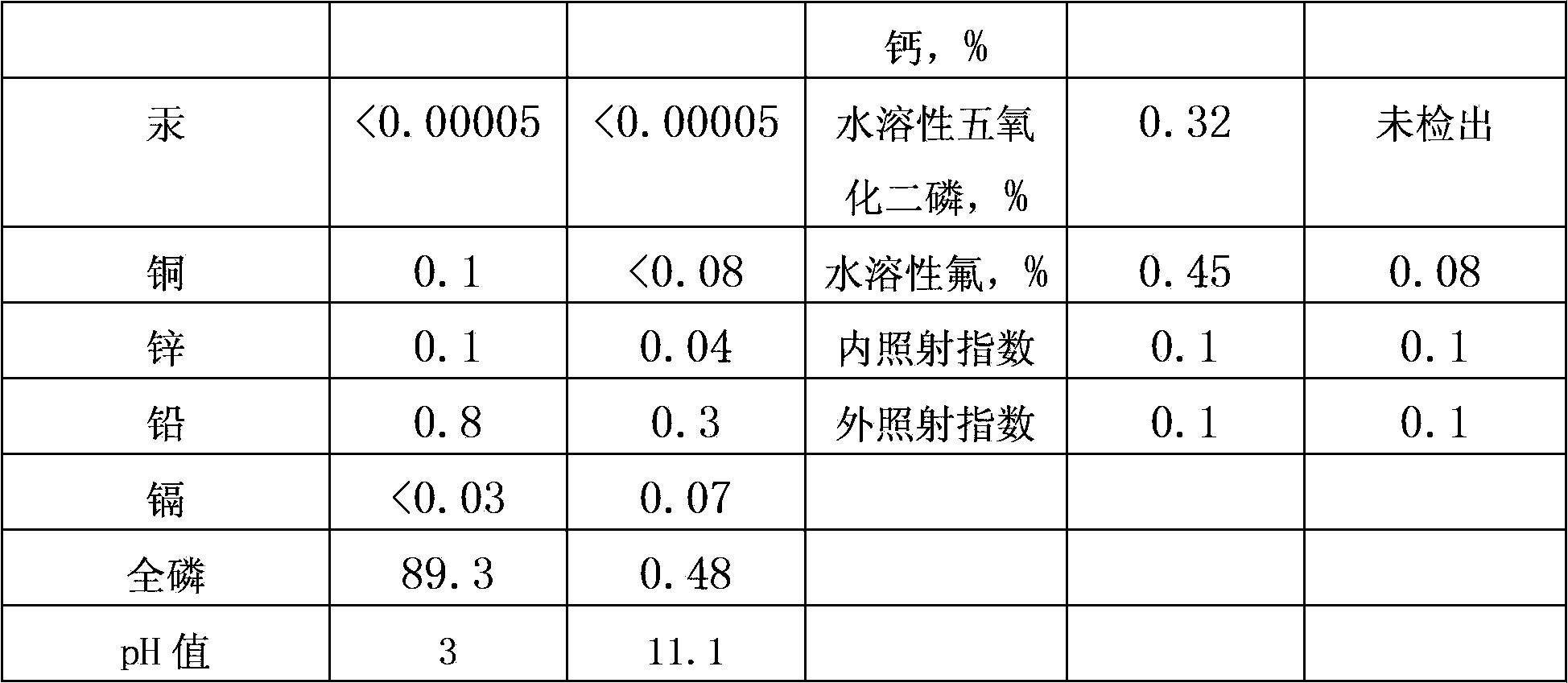

[0047] The performance indexes of the modified phosphogypsum are better than those of the original phosphogypsum, and it has reached the emission standard stipulated by the state.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com